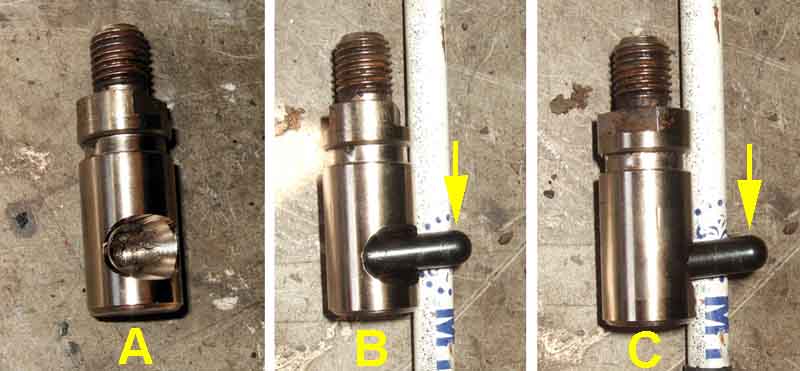

A: The handbrake lever 'cam' with a slot in the side. B: The push-rod retracted. C: The push-rod pushed out - note the distance of the edges of the domed end from the white pencil (arrowed) in B compared to C.

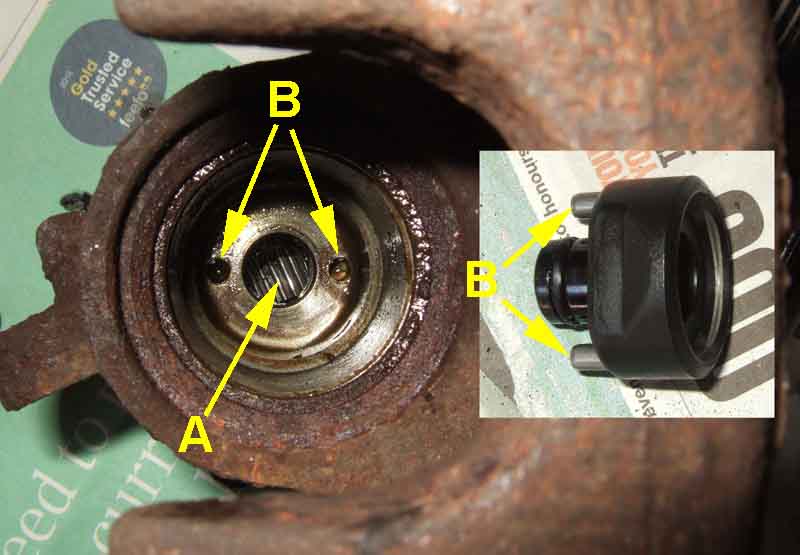

The socket for the handbrake lever cam with the hole for the push-rod to project into the piston chamber (A), and a 'three-quarter' needle roller bearing i.e. with a gap for the push-rod (B).

The bottom of the piston chamber with the hole for the push-rod (A) through which can be seen the needle rollers, and sockets for the pins on the 'adjusting bolt piston' (B). These pins mean that the push-rod can only push B back and fore, it can't rotate it.

The 'adjusting bolt' (A) with a coarse right-hand thread. The head is circular so can rotate relative to the 'adjusting bolt piston' (B) on the left. Although there are O-rings on the head of the bolt and the narrow end of B, which would seem to be the to prevent fluid leakage into the handbrake lever cam area, there is a small hole through the centre of B. Maybe they are just there to stop them rattling. Both the pressure port and the bleed port come through to the main part of the caliper cylinder.

From left to right the 'adjusting bolt piston' with adjusting bolt inserted, a ball-race, spring seat, spring, spring cover and circlip. The circlip locks into a groove in the cylinder wall compressing the spring onto the spring seat, ball-race and adjusting bolt. The ball-race implies the bolt may rotate wrt the other parts, but how and when I don't know, there is going to be a fair amount of friction between the bolt and the 'adjusting bolt piston' from the O-ring on the bolt if nothing else. When the handbrake is operated the 'adjusting bolt piston' and bolt are pushed out against the spring compressing it, towards the piston, making the spring a 'handbrake retractor' i.e. pushing the bolt, 'adjusting bolt piston' and push-rod back to turn the cam to move the lever to push the handbrake cable back.

The piston components from left to right: Circlip, washer, spring, and threaded insert.

The head of the threaded insert is square, slightly domed with cross-cuts, and the inside of the cylinder is more or less a matching shape. This reminds me of the MGB rear brake adjuster which has four angled flats, and drops into one of four positions 90 degrees apart as it is turned. The insert will turn relative to the piston, but it has to be retracted about 4mm to do so against a stout spring.

The outer face of the piston on the left, and a rewind tool on the right. Strictly speaking you should be able to rotate the piston with pretty-well any flat-bladed tool, but after some years the piston is bound to have stiffened up. This one took a lot of force for dismantling, I have seen some versions of the tool with a screw and plate that clamps the tool between the other side of the caliper and the piston, to prevent it jumping out as mine did several times, but they are a lot more expensive.

We know that as the pads wear the piston moves out, and has to be turned clockwise i.e. screwed back onto the bolt to fully retract it again in order to fit new pads. As the pads wear the bolt must turn relative to the piston insert, but what causes that to happen? Is it the bolt that turns? Or is it the piston insert with or without the piston?

As the handbrake is operated the bolt is pushed towards the piston compressing the bolt spring, and via the threaded insert pushes the piston out to clamp the pads onto the disc. At this stage the piston spring is not affected. Releasing the handbrake allows the bolt spring to push the bolt back, which via the push-rod pushes the caliper lever back and pulls the piston insert back. Potentially this could compress the piston spring, but in practice I can't see that happening because there is nothing stopping the piston coming back other than normal seal friction. What it will do is almost certainly pull the piston back further than a normal caliper piston does, which is solely from distortion of the seal as the piston is pushed out, pulling the piston back. I've operated the handbrake lever on the new caliper several times before installing it and the pistons show no sign of staying out, or inching their way out.

But as the footbrake is applied hydraulic pressure is pushing the piston out directly. On the face of it this will push the piston away from the threaded insert, but needs to compress the strong spring inside the piston. This will try to pull the insert with the piston, which will pull on the bolt, which in turn is being pressed back against the 'adjusting bolt piston' by its own spring. The piston spring is significantly beefier (as shown but putting the two end to end and clamping them up in a vice - the bolt spring flattened whereas the piston spring barely moved) and will tend to pull the bolt out of the 'adjusting bolt piston'. When hydraulic pressure is released, the normal piston seal action will tend to pull the piston, back, but so will the bolt spring if that has been pulled against its spring at all.

So far so good, but what unscrews the bolt from the piston insert? Or is it the piston insert, with or without the piston, that unscrews itself from the bolt? Is it the coarse thread on the piston and insert, with the insert being pulled back and released again with each application of the footbrake, together with clearance in the threads, that does the job? An enquiring mind would like to know.