The all-chrome (this is a rear with provision for the number-plate light) have a welded bracket with nut inside for a standard bolt that comes through from the other side of the mounting iron: (Moss Europe)

An original rubber-faced rear with long bolt under the facing strip:

Some suppliers have new rubber-faced with the long bolt already fitted: (Sussex Classic Car)

Long bolt BHH877B for the above type: (Sussex Classic Car)

Some sell a kit of parts including the long bolt and facing strip, washers and nut; some needing this long bolt but without it; and some suppliers have the rubber-faced with the earlier welded bracket that takes a shorter standard bolt:

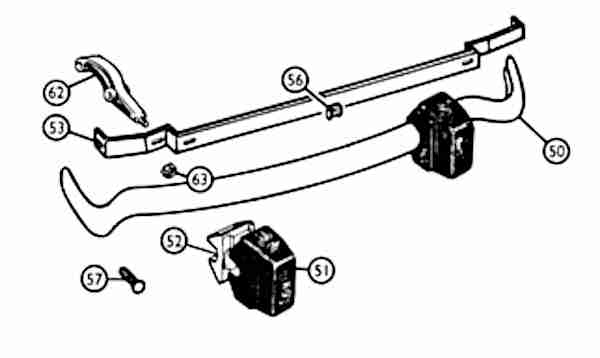

North American 1974 'Sabrina' rubber overriders to pass impact tests had a completely different 'spring' and mounting arrangement. The rubber over-rider with supporting structure (51, 52) bolts to the spring (53) immediately inboard of the mounting point for the spring to the bumper iron (62). 56 is a central distance piece between the spring and the bumper, there are other distance pieces for the over-riders and bumper ends not shown: (Moss.com)

The bumper with three holes across the back instead of four (plus two in the ends as with all chrome rear bumpers). The over-riders bolt through the outer holes to the spring, and there is a single chrome-headed bolt in the middle (with support bracket 56 in the above drawing) bolting the bumper to the spring. Oddly this is from an Australian site but there is no indication (I can find) that these bumpers were used there:

Clausager says that they were moved across to give more clearance to the fuel filler cap, but that doesn't really hold water (I didn't fit the Sabrina style to my roadster of course, it just so happened that the best picture I found of the back was of a car of the same colour):

They do have more clearance, but that is because they are lower, they overlap in the vertical plane almost the same amount by the filler. It's my contention that the move puts the two mounting points on the spring - one for the over-rider and the other for the bumper iron - side-by-side instead of several inches away which will better cope with the impact test. The fact the spring was thicker as well tends to support that.