Plastic fans

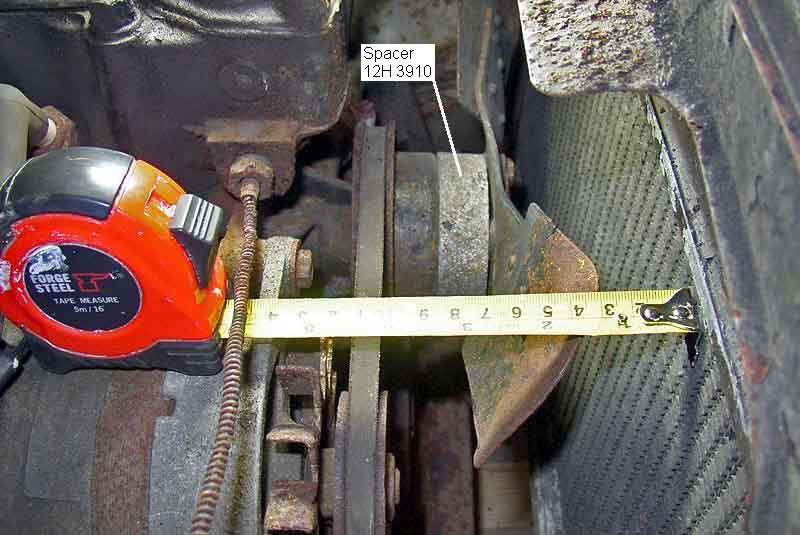

Mechanical: A general view of my mechanical fan, installed the wrong way round, in relation to the pump, alternator and radiator. The free end of the measure is against the back of the radiator core, and taken to the closest part of the blade is about 1 3/4"

Electric fans

Radiator packing strips

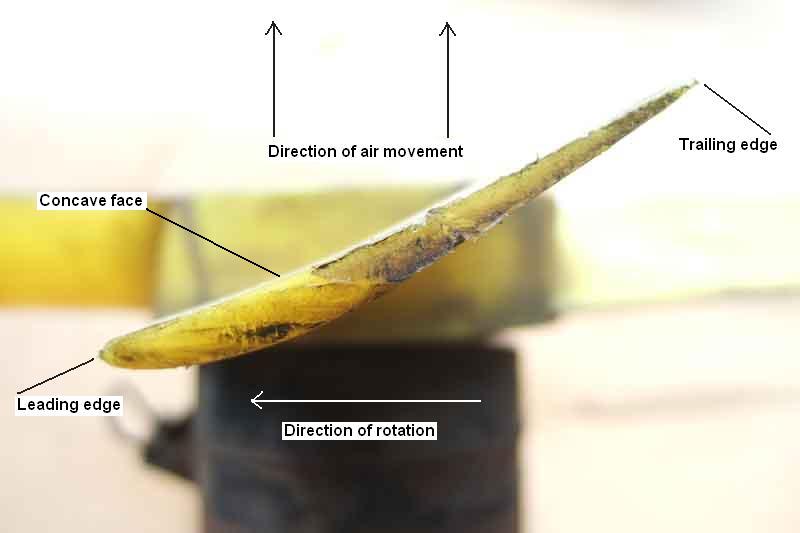

Logically this should be the side of the fan that faces the engine, with the concave and smoothest surface best able to push the air towards the engine i.e. pull it through the radiator.

This should be the side that faces the radiator. Note how much higher the central boss is off the ground, which alters the relative distances between blades, engine and radiator according to which way round the fan is mounted.

Steve Loft's engine clearly showing the spacer mine lacks, and the blades the correct way round, with a clearance of 1 1/4" to the core.

2nd-hand spacer. Not pretty but serviceable.

It is 7/8" thick, and has tapered sides being 3 1/8" across the flat face and 3 1/16" across the recessed face. Presumably it will be obvious which way round it goes from the relative diameters of the pulley and fan faces, but in the Parts Catalogue it is shown with the flat (wider) face forwards.

Spacer cleaned up and fitted, fan repainted, and now the right way round, but still 1 3/4" clearance to the core, compared to Steve's 1 1/4". We both have 4" to the edge of the fan belt, but the blades on my fan seem to be angled away from the rad compared to Steve's. Whether that is how they have always been, or whether whoever fitted it the wrong way round bent them that way either to clear the engine or get closer to the rad, I'll never know. As Bee's cooling is fine it's not worth doing anything about it.

David Bolton's 6-blade fan on a UK 72 shown for comparison, also about 1 1/4" clearance to the core. Note the long-nose pump and pulley, and hence no spacer and short bolts (however it could be a short-nosed pump with the spacer inside the deep pulley). Note all these fans rotate clockwise when viewed from the front of the car.

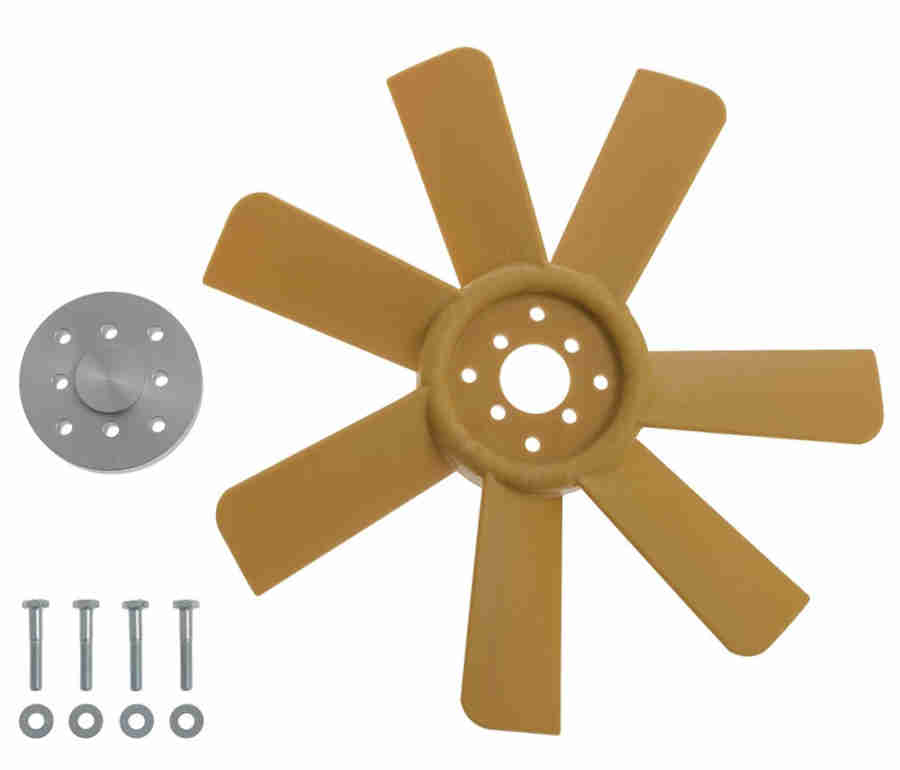

Plastic fans: Note that according to this BL bulletin 7-blade plastic fans cannot be used with the long-nosed pump, but see this Moss version.

7-blade plastic fan correctly orientated, with the deep dish facing away from the engine, and the slightly curved leading edge of the blades for clock-wise rotation.

Fan the wrong way round, blades fouling engine parts.

Correctly fitted, blades well clear of thermostat housing, alternator etc.

Moss 7-blade plastic - a different design to the original 7-blade plastic. This has to be fitted with the deep recess facing the engine instead of facing the radiator, and short-nose pumps need the original spacer as used with metal fans, and long screws. This fan can be used on long-nosed pumps without the spacer, and short screws.

The original 7-blade from 1974 with metal insert: (English Parts)

Arrow showing direction of rotation, anti-clockwise when viewed from the front of the car.

Showing clearly defined blunt leading and tapered trailing edges.

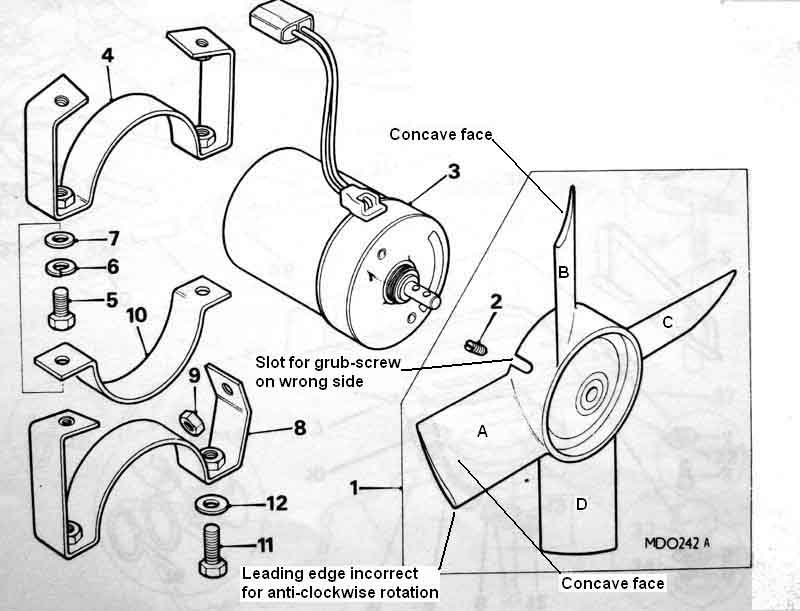

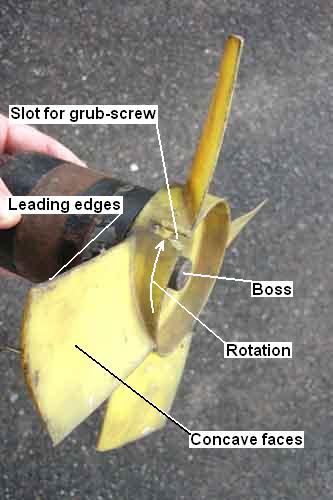

Note this drawing is from the Leyland Parts Catalogue and has several errors. The slot for the grub-screw and hence the boss should be facing away from the motor, the leading edges are on the wrong side for anti-clockwise rotation, and three of the concave faces (B, C and D) are facing the motor and one (A) facing the other way! With the exception of the concave face on A all the other aspects would be correct if the fan was turned round.

Note also that the upper brackets 4 (right-hand) and 8 (left-hand, V8 and North America) must be positioned the right way round or the fan blades will not be square to the radiator.

Fans as fitted to my V8:

Faulty motor and fan as removed from my V8, as an assembly as I wasn't able to remove the grub-screw:

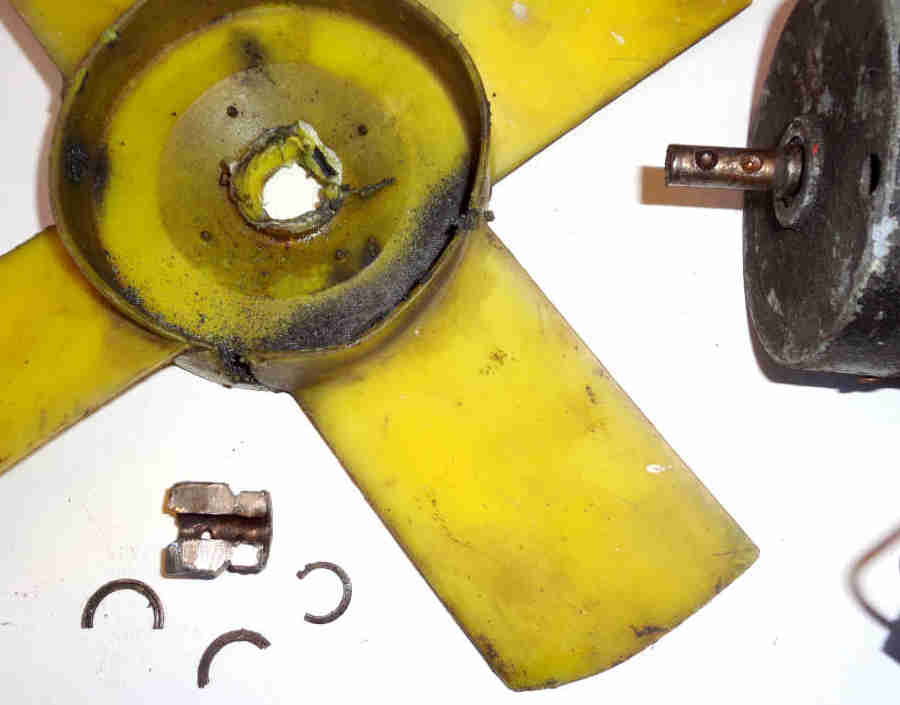

I had to replace both as I was still unable to remove the grub screw off the car. I had several attempts at drilling the grub-screw out at various times but still couldn't part them. Years later when someone found his blades the wrong way round on his motor, the grub-screw broke when trying to unscrew it, so I had yet another go at mine. This time with angle-grinder, chisels, wedges and a big hammer I finally managed it!

As you can see the motor shaft has two indentations for the grub screw so the blades can be fitted either way round, according to application. For both 4-cylinder and V8 MGBs with the motor and fan in front of the radiator the indentation nearest the end of the motor shaft is the one to use, and the end of the shaft should be flush with the face of the fan boss.