Remove the radiator:

Remove the fan and pulley, bottom hose and alternator where it connects to the pump:

Remove the pump - unless you have been able to drain the block more coolant will drain out:

Check this bypass hole goes up to the bottom of the thermostat ...

... and this one goes up into the head. Use stiff wire and compare the amount you can insert with the outside afterwards:

Showing the difference between an 18GB block and an 18V block: (Edouard Prioul)

New pump installed, ready to refit the pulley, fan, radiator and bottom hose:

The 'original' bolts as removed (all UNF), barely 1/4" engagement with the block, despite the drilling being about an inch deep:

The originals (left) are supposed to be 1 3/4" and 1", but are about 1/8" shorter than that. The new ones I bought based on confusing and incorrect information on the MGOC web site (since corrected following notification) are way longer, even though they are only supposed to be 1/8" longer:

As fitted to the pump A is the long bolt and slightly too long, B is one of the short screws and way too long. C is an original short screw for comparison:

After cutting 1/8" off the long bolt and 5/16" of the short screws, and with washers under the heads, there is more engagement but still well clear or bottoming:

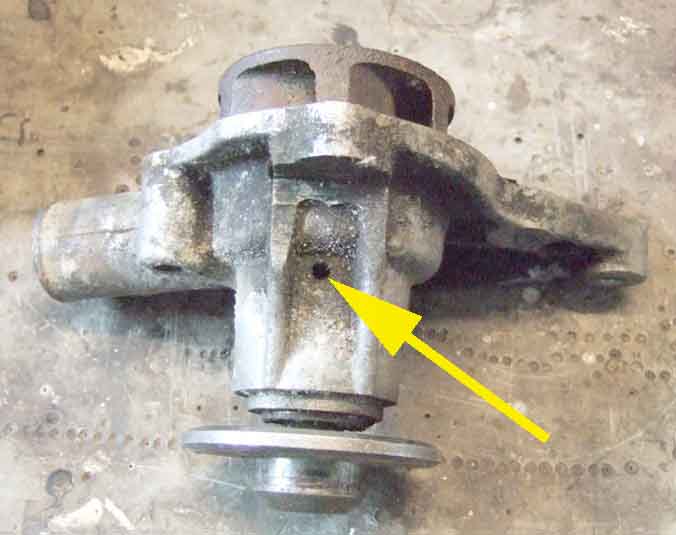

Drain holes: An alloy pump purchased in 1990 that had to be 'modified' to fit. Underneath immediately above the bottom bolt so slightly offset towards the alternator:

Another - cast-iron this time - purchased in 1997 prior to touring in France as the alloy one was weeping during warm-up. However it didn't get any worse and was only replaced with this one in 2014 as part of an investigation into a cooling system problem, but only lasted until 2018 before it started leaking. This hole is larger and more central, slightly offset from the bottom bolt:

This site says it is to allow coolant to escape while the seal is bedding in on a new pump, otherwise it would contaminate the bearings. Some pumps have a reservoir to trap this, which boils off though a vent higher up as the engine warms to prevent mechanics thinking the new pump is faulty. I doubt ours have that but it's still worth running a new pump for a while to see if any slight dripping 'heals up'. The alloy one above seeped very slightly during warm-up for 30 years, then stopped for the remainder of the run, so I let it be.

Avoid pumps with pressed impellers as on the right which are less efficient, also plastic ones which can crack and spin on the shaft at high rpms: (Peter Basher)