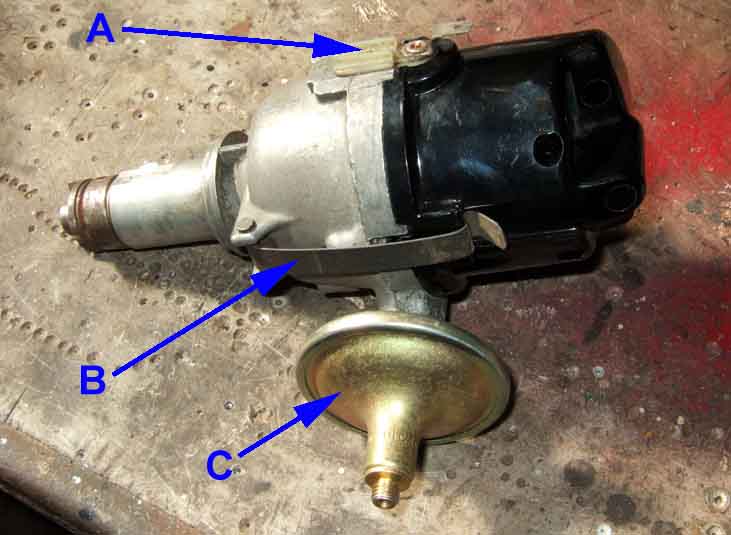

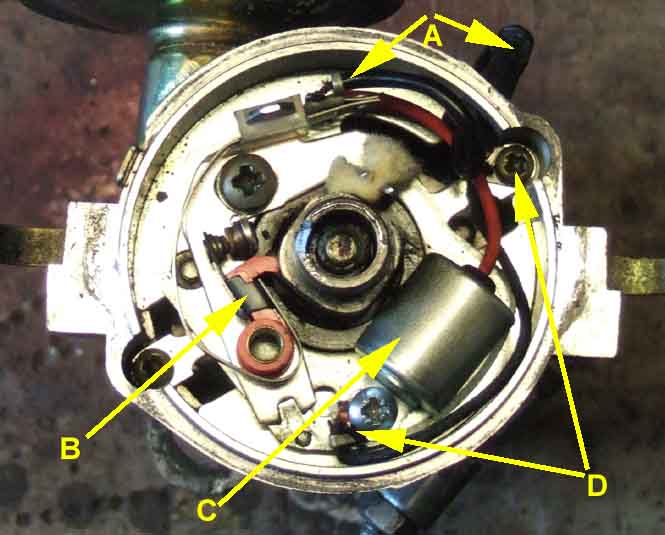

25D4 distributor: 'A' spade terminal for the points connection on the side; 'B' long, almost flat clips; and 'C' vacuum advance capsule. This early capsule has a screwed connection for a copper vacuum pipe, later versions have a push-on fitting for plastic tube:

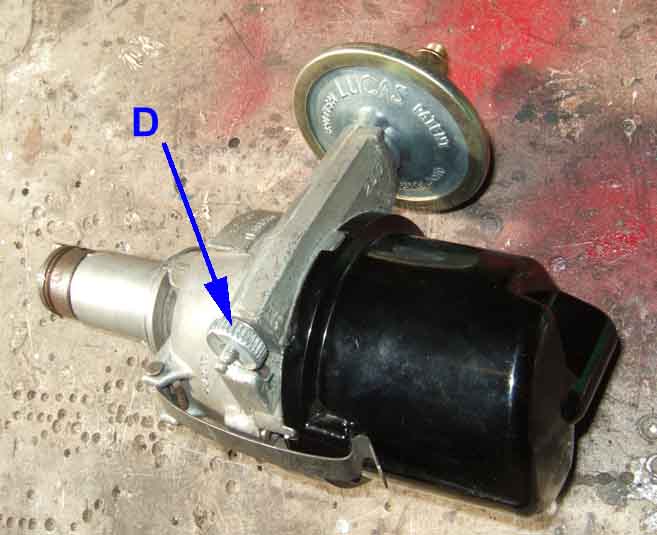

The vacuum advance capsule passes through a moulding on the side of the distributor body and has a knurled adjustment wheel 'D' at the far end:

'Side-entry' cap, which positions the HT leads well clear of the RHD steering column and UJ, unlike top-entry caps. Cut ends of the leads push into the holes:

... and are secured with screws:

'Top-entry' cap, these silicone-cored leads have crimped metal terminals that push into connector sockets inside the cap:

Nothing inside the cap except the five connections, the centre one being a spring-loaded 'carbon' or graphite rod:

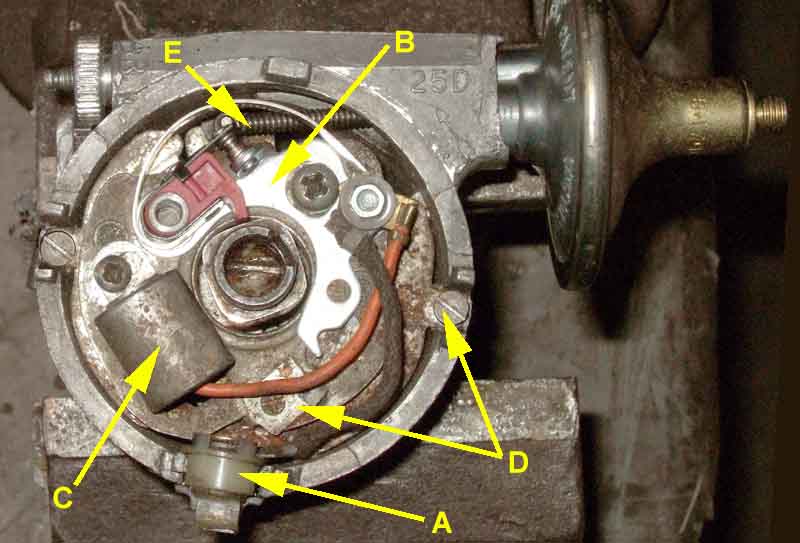

Under the cap: 'A' the points/coil terminal with a cloth insulated wire to the points terminal stud; 'B' points; 'C' condenser with wire to the points terminal stud; 'D' there should be a cloth-insulated earth wire from a riveted terminal on the points plate to a fixing screw, 'E' the vacuum advance actuator on a pin on the points plate:

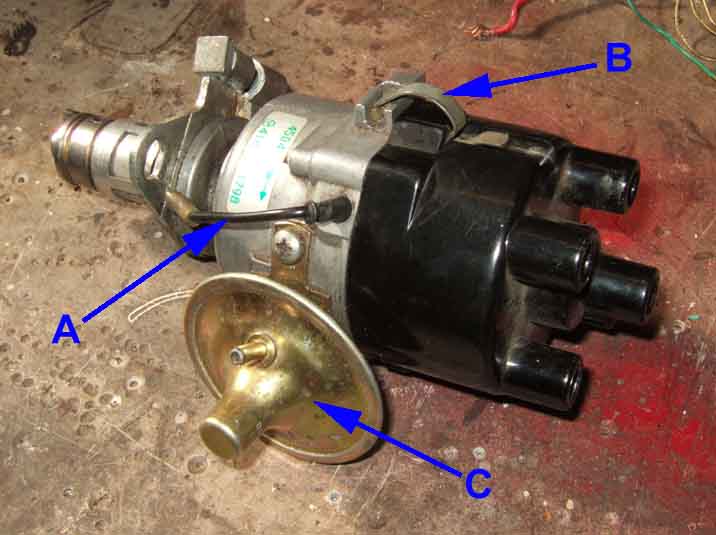

45D4 distributor: 'A' the points wire passing out through a hole on the side of the body terminated with a male spade; 'B' short curved clips; and the vacuum capsule with a push-fit connection. 'Top-entry' cap, there do seem to be side entry caps but they are screw-down not clip on used on the original Mini:

'D' the vacuum capsule goes into the body and is screwed to the outside of it;

Cap removed: 'A' points/coil wire entering through a hole in the distributor body; 'B' points; 'C' condenser, the condenser and the points wire have a common connection that slides under a clip on the points spring; 'D' earth wire from condenser screw to points-plate screw:

'Top-entry' cap, with connector sockets for push-in leads with connector plugs:

Again nothing inside except the five connections:

Clamp Plate: Both distributors are attached to the block using a clamp plate. This has a bolt and nut that clamps the plate to the distributor body, it's important not to overtighten this as it can distort the alloy body of the distributor which can then jump out when the engine is running. There are two styles - one as here with a square-headed bolt (trapped bolt) where the hex nut torque is 2.5 ft.lb. and the other with a square nut (trapped nut) and hex-head bolt where the bolt torque is 4.16 (!) ft.lb.:

It has two holes for screws into the block, these are elongated so as to give a certain amount of scope for adjusting the timing without slackening the clamp nut. If you need more adjustment than that then you may need to slacken one of the block screws as well as the clamp nut before the distributor will turn: