3-sync non-OD with the lever mounted on the drive shaft tube:

3-sync OD with the lever mounted on a longer 'remote control' housing on top of the gearbox: (The Classic Cars Journal)

Comparison of 3-sync non-OD (left) and OD (right): (Clausager)

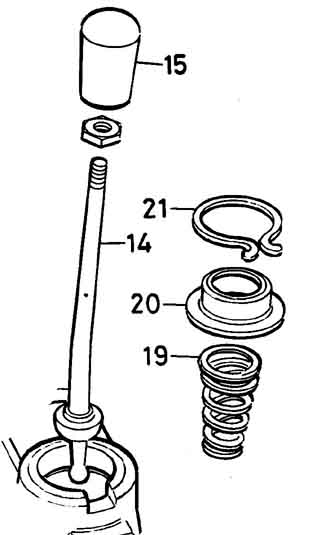

Mounting arrangement - spring (19) pushes the lever (14) into the socket, cover (20) compresses the spring, and circlip (21) locks the cover in position: (WSM)

4-synch - non-OD and OD using the same 'remote control' housing: (Clausager)

Mounting arrangement - the retaining plate is secured with three special bolts and Thackery washers into the remote control housing:

Shouldered bolt and Thackery washer. The bolt tightens through the retaining pate and washer onto the gearbox casing, compressing the spring of the washer, which presses the retaining plate down onto the large ball of the gear-lever, pressing it into the socket in the casing:

Anti-rattle bush, with the slit arrowed:

An original bush on the left with a significant chamfer to aid insertion into the gearbox shaft socket, once the bush has been fitted to the ball-end of the cabin lever. The bush on the right is a replacement with virtually no chamfer and was impossible to fit, until I cut more of a chamfer. I tried fitting this to the gearbox first but when fitting the lever it just pushed it straight out, fortunately to fall on the floor and be retrieved. However Bill Etter was able to fit the bush to the gearbox before fitting the lever:

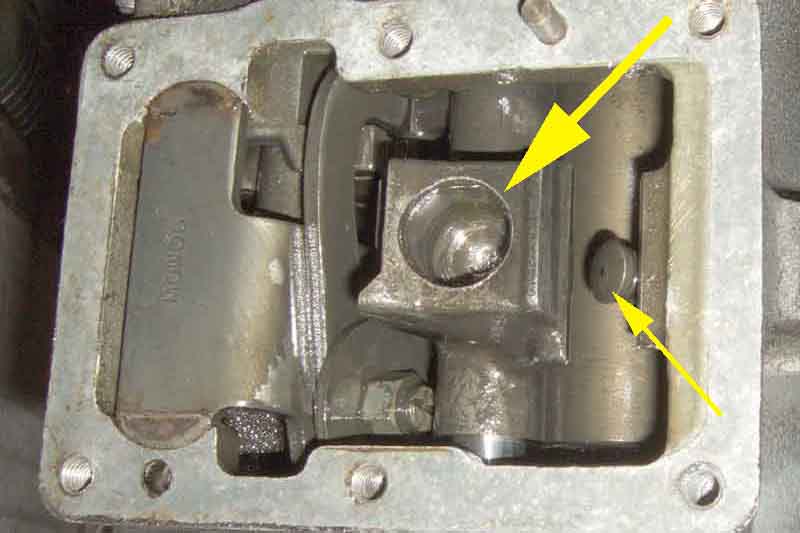

There is an identical bush on the other end of that gearbox shaft (large arrow). Also shown is the overdrive switch plunger (small arrow), with a chamfered head where there is OD on 4th only i.e. this V8, also later North American spec 4-cylinder:

The socket for the bush in the gearbox selector shaft (large arrow). Also shown is the reverse light switch plunger (small arrow):

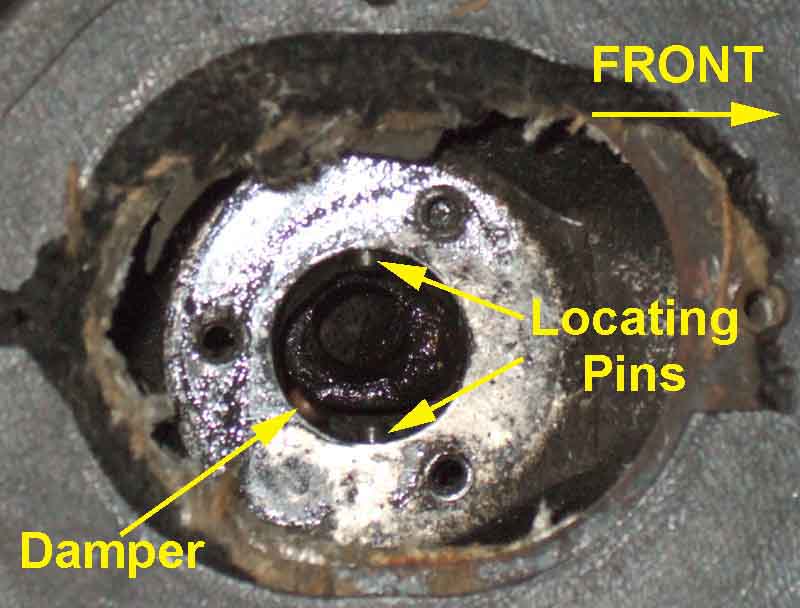

Two locating pins and damper on a pre-77 4-synch, 77 and later only have one slot in the ball and hence only one locating pin:

4-synch gear lever with a rearwards kink ...

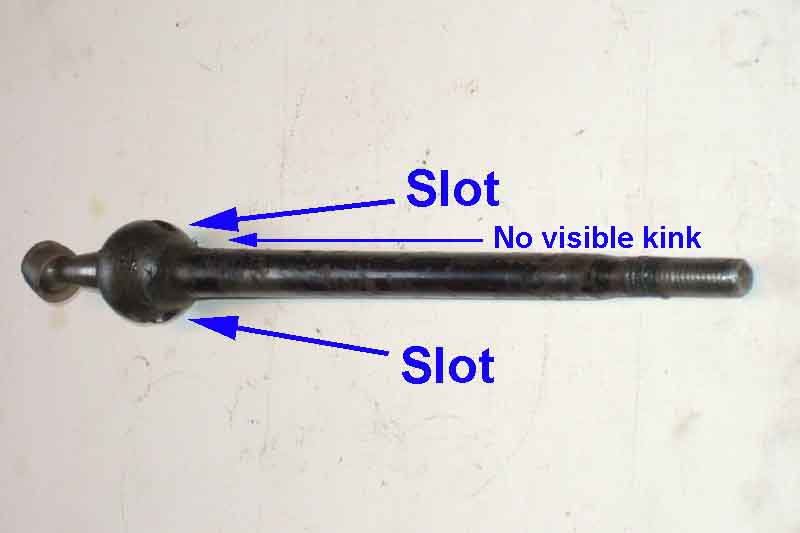

... but no sideways kink, and two guide slots ... which means the gear lever could be installed the wrong way round:

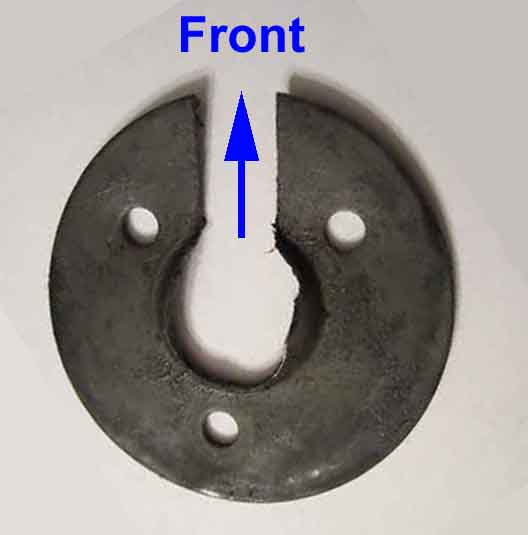

Orientation of lever seating plate 22B524 on a 4-synch

Raised portion on the left:

1977 and later manual switch on the gear knob: (Upgrades4MGs and WorthPoint)

Lever with thickened section, said to be a harmonic damper, but there are still complaints that this knob buzzes. Guide pin slot on one side only (not visible here) so the lever can only installed in the correct position. It may be that this is a 'steel-rubber-steel' sandwich so there may be the risk of twisting the upper part of the lever relative to the lower part if you apply too much force to the knob nuts:

The retaining plate DAM2576 for the above lever:

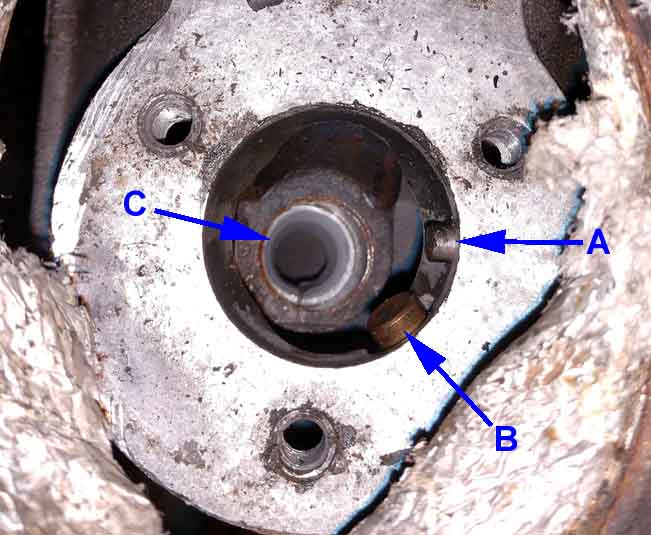

77 and later housing with single locating pin (A) which together with only one slot in the ball of the lever ensures the lever can only fit in the gearbox one way round, unlike earlier. Also showing the damper (B) and bush (C). In this case the gear lever could be fitted and removed with the bush already in the gearbox shaft: (Bill Etter)

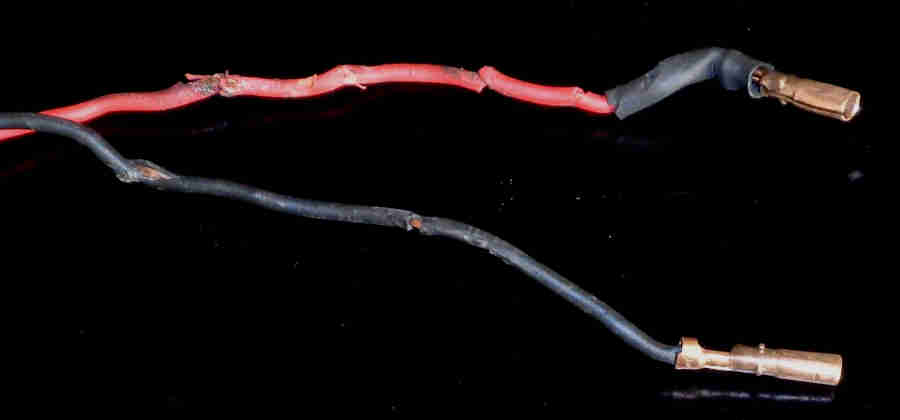

A good indication of why the OD circuit especially for this manual switch should be fused - single-insulated wires passing through the earthed gear lever. Red and black here implying one 'live' and one earth, replacements are brown and blue implying 'live' and 'neutral', but both wires carry 12v when the manual switch is on:

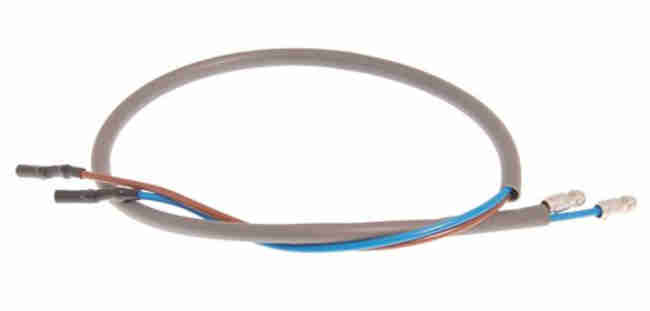

Gear-lever sub-harness 153726 with bullets to connect to the gearbox sub-harness and 'sleeve' connections to the switch. Get one like this with a 'loose' sleeve' that can be slid towards the switch connections so protecting the wires where they are in the slot in the gear-lever, not one with a tight sleeve (like 2-wire lighting cable):

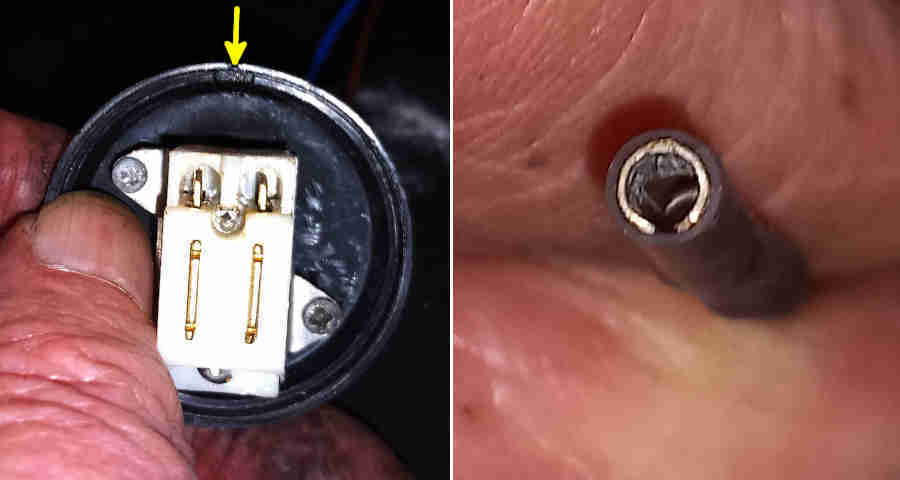

The sub-harness connections to the switch are cylindrical but the switch (520999a) terminals themselves are not pins but flat blades. The cylinders are slit lengthwise and this slit slides over the blades on the switch. If loose pinch them up carefully to close up the slit, don't flatten them. Note the location tab on the cap arrowed:

Ring-nut C30623 goes inside the knob and chrome nut C30505A goes under the knob to secure it. The ring-nut can be lightly screwed on with a suitable implement then the chrome nut tightened with a 5/8" spanner (it has flats) from below to secure the knob: (Moss Europe)

Gear lever with chrome nut screwed on and sub-harness passing up the slot, sleeving extending up above the slot (foam sheet behind for clarity):

The knob has a 'key' that fits in the lever slot so the knob can only fit in one orientation and not twist round:

Knob fitted, slotted nut inside, cap locating tab slot arrowed:

Oddly the knob has a wide slot for a locating tab on the cap and a narrower slot at the rear whereas the cap only has a narrow tab at the front (see above). The result is that the narrow cab tab in the wide knob slot allows the cap to swivel a bit, and it's not a tight fit. The knob can only go on the lever in one orientation because of the slot in the lever and the 'key' in the knob, and the lever can only go in the gearbox in one orientation because of the single locating pin in the gearbox ('A' above).

A replacement cap was a very poor fit anyway, loose instead of the ridge inside the cap clicking into position over a corresponding ridge on the outside of the knob at the top. Also the wires do not go straight up from the lever to the switch but take a dog-leg, and a new sub-harness was pushing the new cap up at an angle. Eventually three layers of insulating tape were needed round the recessed part of the knob before the cap would fit firmly and stay in place.