Front bow fouls the body

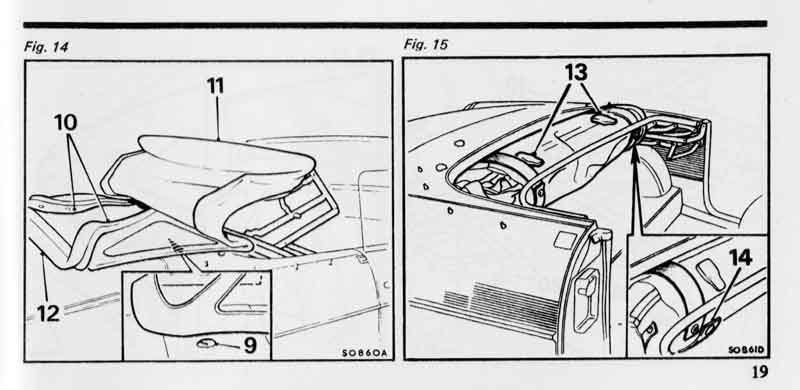

This is one of the illustrations from the Driver's Handbook:

But I don't like draping the material over the rear panel and boot so came up with a modification to the process to avoid that.

Fold the rear section forwards over the top:

Tuck in the quarter-lights (you can see one of the cords that pulls the rear bar into the correct position when the hood is erected):

Lower it into the tonneau space, holding up the rear edge to lift the rear bar and stop it jamming on the wheel arches:

Lay the rear part over the rest of the assembly (closing the catches first). The folds should all be in the material not the windows, and the strips between the rear window and quarter-lights should be lying over the header rail clips:

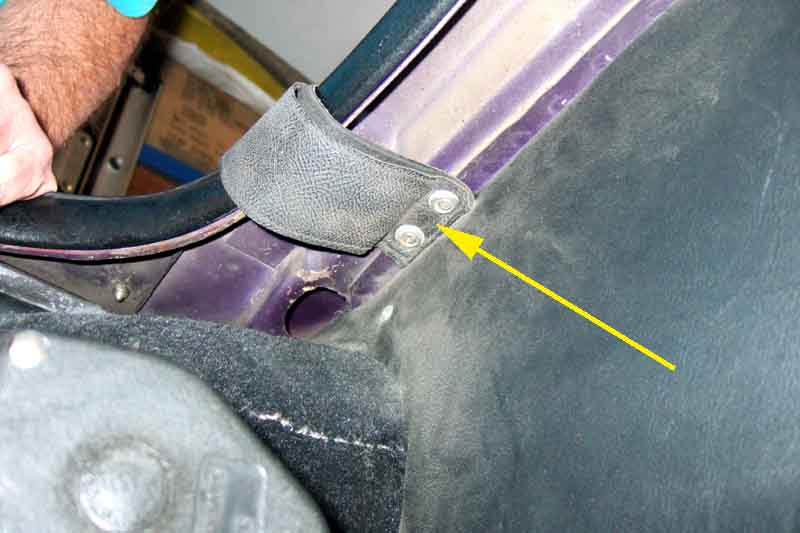

Hood straps in use, although I never bother. With the inertia reels in the lower rear corner as they are, and the belt exiting horizontally, leaving the hood hanging has never impeded belt extension or retraction, and the tonneau cover used as a hood cover hides it all anyway:

Hanging down in the corner between the back panel and the arch:

Attachments:

The folded hood drops down almost completely into the space behind the seats (this space is the 'tonneau', not the cover that goes over it, that is the 'tonneau cover'). Originally it stuck up much higher than this and I couldn't fasten the full-length tonneau cover over it. I took the hood frame off and placed it on the floor and lowered it, and I could see how one strut each side was jamming. By bending those struts a bit more it suddenly collapsed all the way. Unfortunately I can't remember which strut it was!

Now the tonneau cover fits over the hood neatly and clips to the heel-board snaps. However the downside is that I can't now throw the hood back and leave its snaps fastened all the way round in preparation for a quick ... erection, so to speak:

Sticking up: (This and the next three pictures from Martin White)

Although the rear bar rests on the rear arches the remainder of the frame cannot sink right down:

The strut that needs to be adjusted:

The result:

65 with the later Michelotti frame down all the way, as well as still being fastened to the rear panel. It has the rear window zipped out though, so maybe that makes a difference:

With inertia reels fitted in this position ...

... the hood drops down, and it is the frame resting on the arches (see witness mark on the arch carpet above) that stops it going any further, not the inertia reels. I never use the straps to fasten the hood into a bundle, just let it all hang down, but it doesn't affect retraction of the belts:

The most convenient position for the front bow is to point down and slightly back at the same angle as the middle bow ...

... then when folded it points straight forwards and tucks inside the cockpit rail:

If it is pointing too far backwards ...

... it will be pointing straight down when the hood is folded and foul the body:

If it is pointing straight down when erected ...

... then when folded it won't foul the body but will be pointing up upwards, which is less convenient:

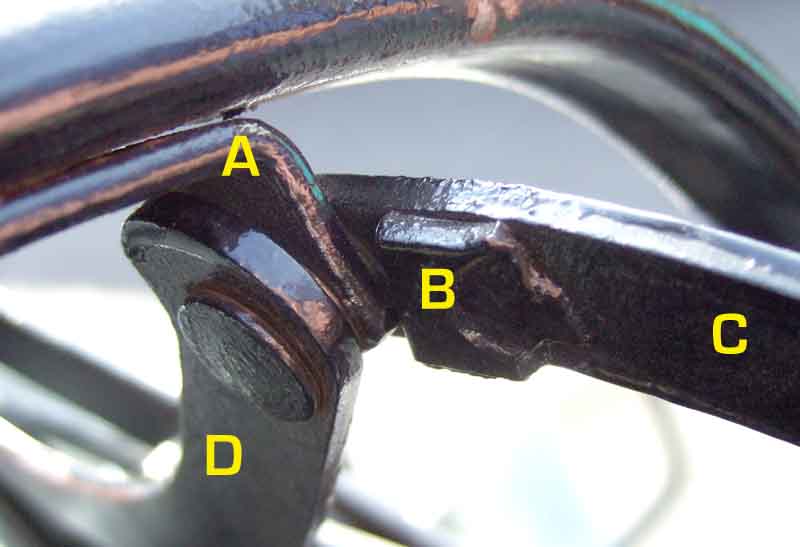

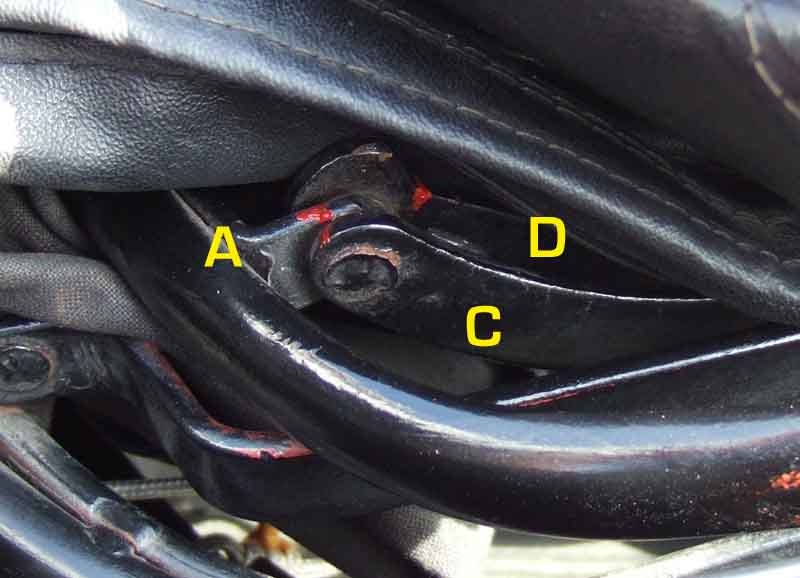

The front bow support 'A' looks like it should more-or-less butt up against block 'B' giving just a small amount of movement of the bow. 'C' is the short rear strut and 'D' the longer front strut. If the side of A should butt right up against the edge of the block then that would put the bow ends pointing straight down as in the two previous pictures:

But given the gap between the bow and the block ...

... and wear in the pivots giving a less-than-ideal angle ...

... the bow bracket can ride up over the block which allows the bow to tilt forwards when the frame is raised, which is when the ends of the bow foul the body when the frame is lowered:

With the frame raised a line of paint marks on the three elements ...

... shows that the bow support 'A' remains aligned to the rear strut 'C', so could conceivably be welded to it:

I root around in my box of scrap metal and offcuts, and find an old Mini rear brake handbrake lever dating back 45 years - some of which has already been used for something else - and find it is the ideal thickness and width, so cut two pieces off ...

... which (having just been placed here) should nicely fill the gap between the two struts better than the existing block. Judging by the effort needed to hacksaw through it's harder than basic mild-steel, probably because it needs to be able to force the shoes on tight without excessive wear in the pivot or where it engages with the shoe:

Old block ground off:

New block welded in place, prior to painting: