W177 jack point under the car - semi-circular cut-outs both sides of the rectangular recess:

'Barbs' push through a hole in the body and the screw expands them to keep the jackpoint in place - but plenty report losing them: (Peter Clarke)

Powerflex W177 jacking adapter matching the shape of the jack point:

Fits snugly inside and around the edge:

W176 jack point - longer in relation to its width, semi-circular cut-out one side and rectangular the other:

eBay W176 jacking adapter - simple rectangle above and circular below ...

... but shown being offered-up into a jack point with semi-circular cut-outs both sides, i.e. similar to the W177 jack point:

The W176 adapter has the rectangular and circular parts a little smaller, but the rectangular part is a little higher:

Only a little chamfering of the edge of the circular part was needed for it to fit my large jack saddle:

However it needs 175mm clearance under the car but there is only 150mm available at the rear and 118mm at the front so the car would need to be driven onto something to raise it about 1" at the rear but more than 2.5" at the front to slide jack with adapter under:

But because the cylindrical section is thinner than the rectangular section positioning the adapter in the jack point first then sliding the jack and saddle under would need less space.

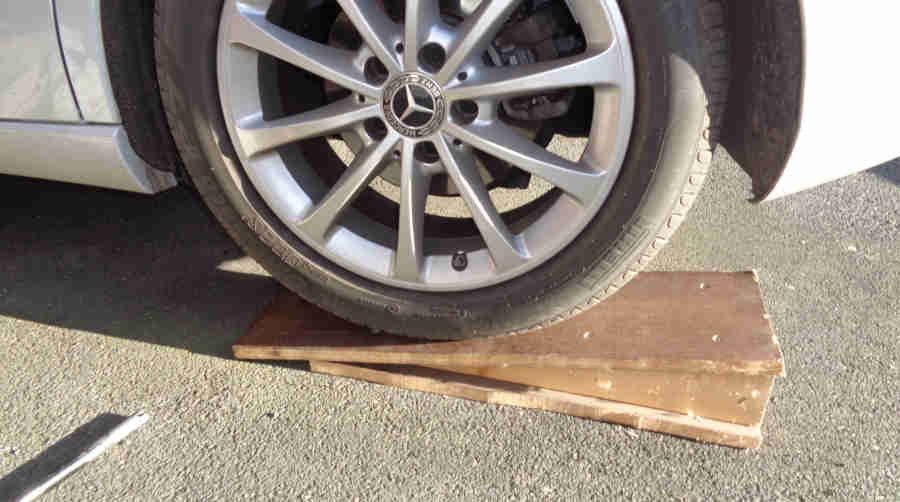

Ramps needed to raise the car this much to get it under the rear jack point:

Concerned about driving off the back of the ramp and flipping it up to damage the underneath of the car I'll probably have to use the metal ramps with the pre-ramps, but even that is marginal given the closeness of the front quarters to the ground and the distance to the wheels:

Cheap adapter not such a good fit, all the weight is taken on the central rectangular section, but that could be trimmed down to put some round the edges:

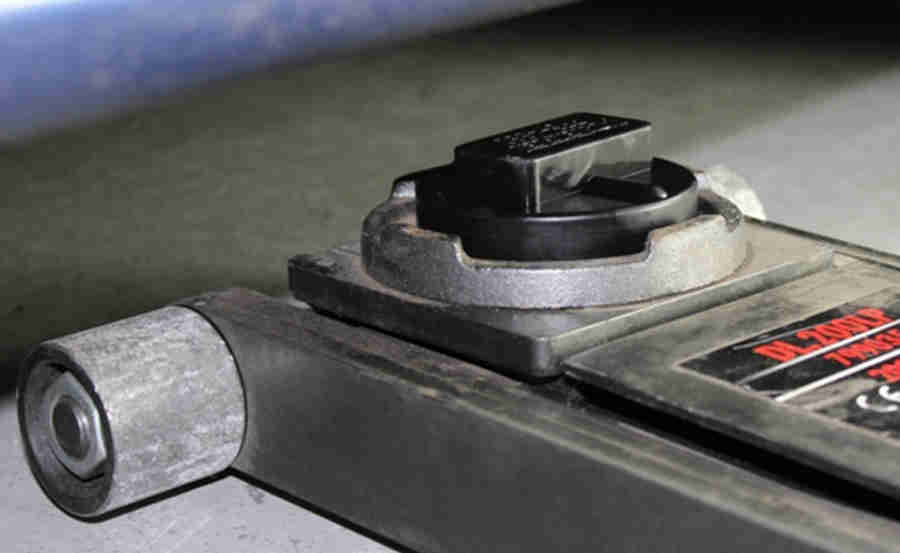

Low-profile jack with a saddle big enough to take a similar adapter and slide under in one go - but expensive at £200:

There are cheaper low-profile jacks but with smaller saddles, but I then had the idea of cutting a circular channel in the base of the correct, larger 177 adapter and that worked well:

Only took a few minutes drilling a series of holes with a small wood drill bit then joining them up. Not elegant, but functional:

I may glue a disc of something to the base of the adapter that sits inside the jack-pad so the central section of that is doing the lifting as well as the raised edges.