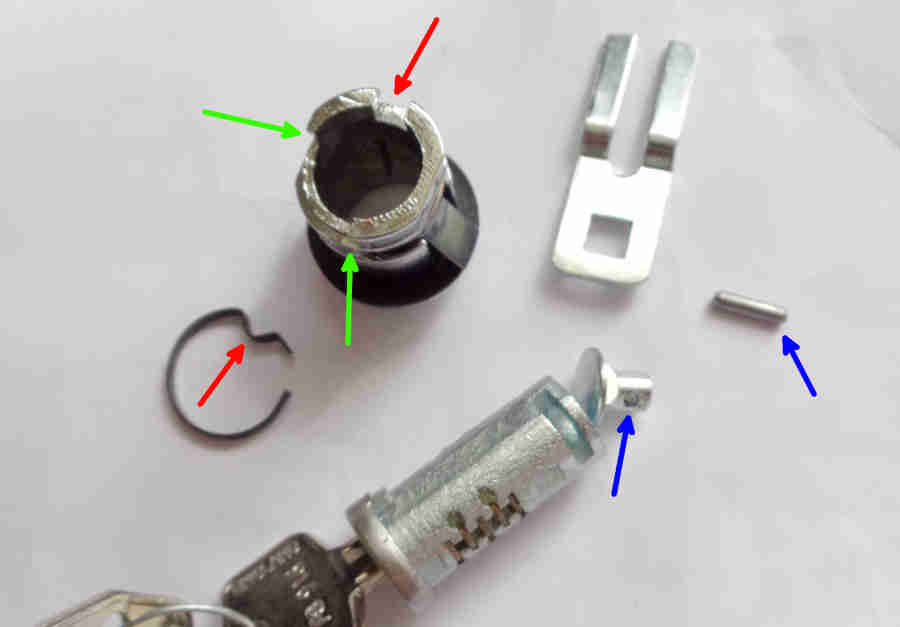

The factory arrangement:

The lock assemblies are handed RH and LH but the barrels themselves are not. The barrels have a 90 degree quadrant containing a pin (red arrows), which goes through the pivot that carries the forked lever. With the locks orientated as they would be in the doors i.e. key slot vertical with the key removed, tumblers at the bottom, the quadrant is in the same position on both locks but the forked pieces point in opposite directions - basically facing forwards in both doors and able to move above and below the horizontal:

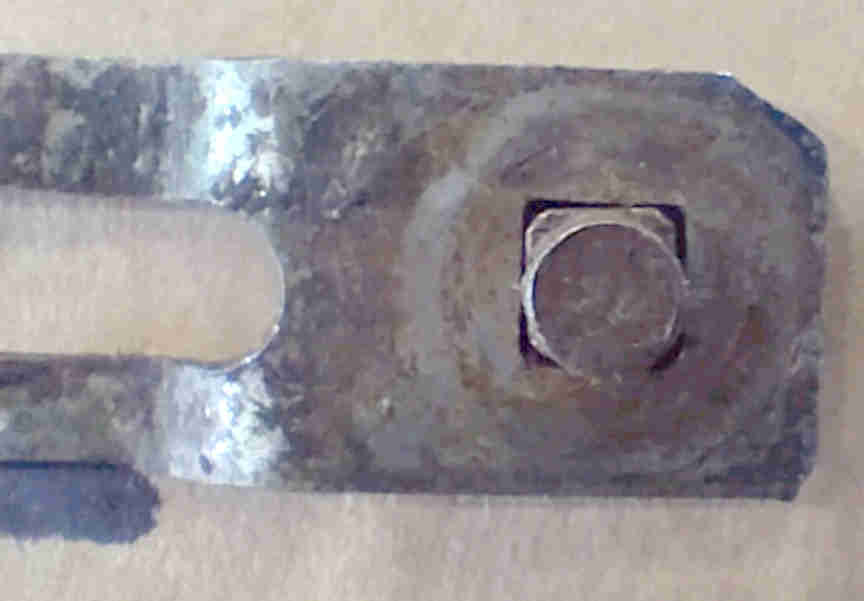

The blue arrows show the pin and the hole in the pivot it goes through. The green arrows show the extent of the quadrant in the lock body that the pin can rotate through as the forked lever is moved up and down. This lever has a square hole, and the portion of the pivot above the hole is also square. The locks are handed by positioning the forked lever in one of two positions 180 degrees apart, and inserting the pin through the quadrant. The spring-clip prevents the pin coming out in use, the notch in the clip sits in the small cut-out in the lock body (red arrows) and the rest of the clip covers the quadrant. The clip can be fitted either way up:

Note that because the forked lever is located on the pivot by a square it can fit in any of four positions, two of which will allow the lever to move about a vertical position instead of a horizontal position and these will not engage correctly with the locking rod on the latch.

The forked lever moves up and down independently of the lock barrel - the pin moving in the quadrant - as the door is locked and unlocked using the internal handle. When the key is inserted and turned to the lock position the barrel rotates moving the pin, hence changing the angle of the forked lever, which moves the latch rod to lock the door. When the key is returned to the vertical position for removal the barrel comes back to its previous position, but this time the forked lever stays where it is, the pin moving in the quadrant. When the door is unlocked the barrel is rotated in the opposite direction, which now moves the forked lever back to its original position, and the latch rod, unlocking the door. When the key is returned to the vertical the barrel rotates but again the pin moves in the quadrant leaving the forked lever and latch rod where they are.

This section was expanded in August 2023 when two people on the MGOC forum were having problems getting the key to lock and unlock the door. At the same time I was looking at the locks and latches on a pals car - which needed new locks as the tumblers were missing so any key or a screwdriver would open the doors, so was a good opportunity to get some decent pictures of a new, shiny, clean lock. Having posted pictures and explanation on the forum Paul Hill discovered that the reason his lock wouldn't reliably both lock and unlock - bending the latch rod would do one but then it wouldn't do the other, was due to wear on the square-sections of the forked lever and its pivot which increased the slop between them and reduced how far the lever would move the rod when turning the key. Given the price of new locks the lever and pivot could be Araldited together ... but make sure the lever is in the right position on the pivot first!:

See here for how the forked lever engages with the latch locking rod.

Fitted - using the original spring-clip, which allows the lock to rotate a little in the door panel despite a location notch, which damages the paint and causes rust despite the fibre gasket:

The after-market kit (parts for two locks in each kit):

As originally fitted to the V8 the driver lock stiffened up quite a bit with the grub-screws fully tightened and I had to slacken them a bit. Thinking that the kit distorts the lock very slightly and some necessary clearance was very small on that particular lock, I eventually got round to removing it and fitting it to my test panel to work out what needed relieving. I was surprised to find it wasn't stiff at all, nor when fitted back to the door. A mystery:

November 2023: Pal ordered a pair for his 78 that we are getting back on the road and they came with two washers - one fibre the same size as the flange on the lock and the other thin rubber with a larger OD that I hadn't seen before. We used the fibre on the outside, maybe the other is intended for the inside but we didn't use it. The locking kit can be a bit fiddly to fit, ideally one hand needs to be in the door holding the 'horseshoe' in position while the screws are tightened from the outside of the inner skin which is awkward for a right-hander on the left-hand door. But by balancing the horseshoe on the lock with the open end pointing down, having set the screws just short of starting to tighten, careful use of a screwdriver tightened the first one up enough without dislodging it then they could both be fully tightened. Afterwards it struck me that with the key in the lock and turned to one side, pulling on the key as if trying to remove the lock from the door while the horseshoe is held in position with the other hand, will press the horseshoe screws against the large washer with enough force to keep the horseshoe in position while the screws are tightened, pulling the lock and fibre washer up to the door skin. Or maybe standing outside the door and leaning right over ...