A lot of worrying crud, probably friction material, on top of the filter, which is what led to the replacement of the OD

Gearbox separated from engine, bit of wood wedged between ring-gear and starter pinion prior to undoing the clutch cover plate bolts to replace the clutch at the same time.

Gearbox on Workmate preparatory to fitting OD

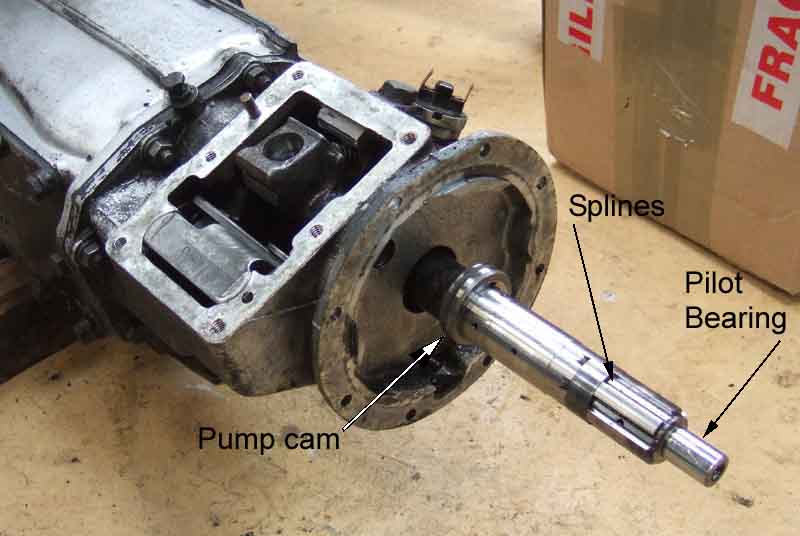

OD pump cam and splines on gearbox output shaft. Just like the gearbox first-motion shaft and crankshaft there is a pilot bearing in the OD for this shaft as well

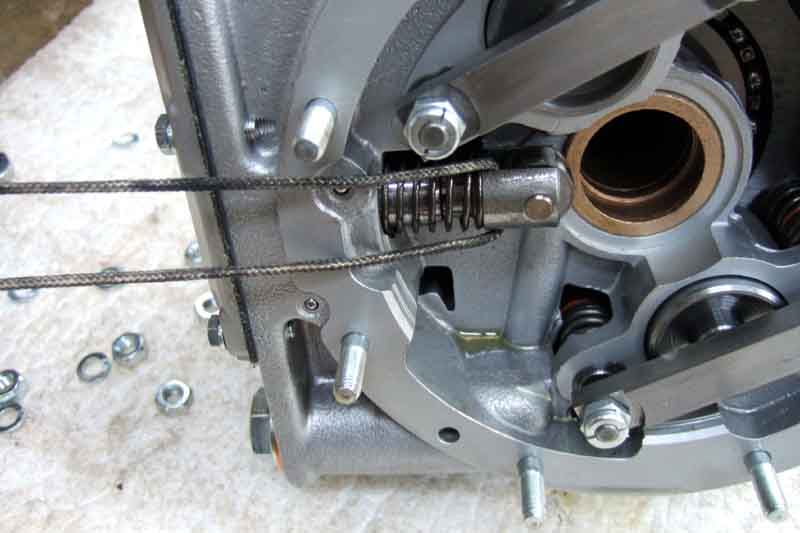

OD pump with cord to pull it back so the roller goes over the cam

Splines just visible inside the OD

Jacking up the OD to enable fitting washers and nuts to two of the studs

OD fitted, time for a celebratory bacon sarnie!

IMPORTANT! The LH overdrive is attached to the gearbox with the solenoid and the manufactures info plate on the bottom. Unlike the D-type where they are basically on the side.

Arrowed is the flat on the casing that allows the removal of the V8 propshaft bolts while the flange is still fitted to the output shaft. Not possible with this 4-cylinder flange, which is smaller.

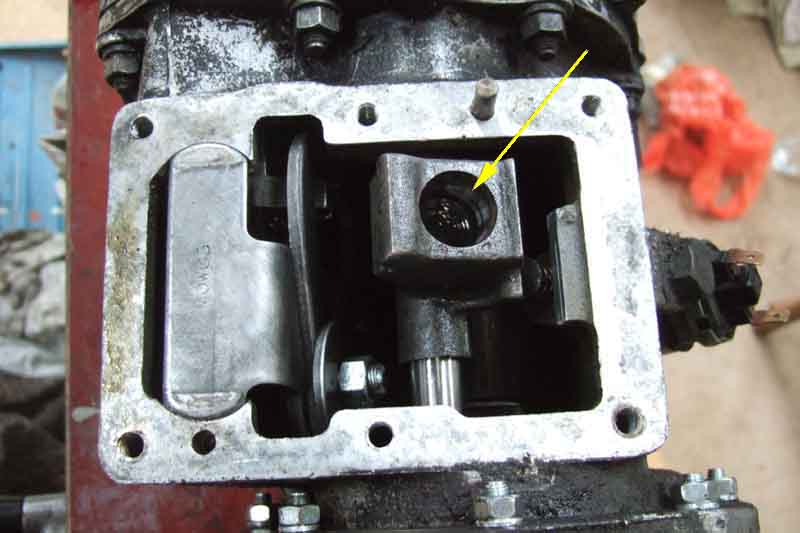

The socket in the gearbox for the remote change ...

... and the split bush on the ball in the tower, which is identical to the bush on the bottom of the gear lever

The disposition of the bottom two bell-housing bolts and exhaust mounting bracket

Back together, gearbox harness fitted, ready for reinstallation. Incidentally I believe now that the gearbox harness should go under the remote control extension, not above it.