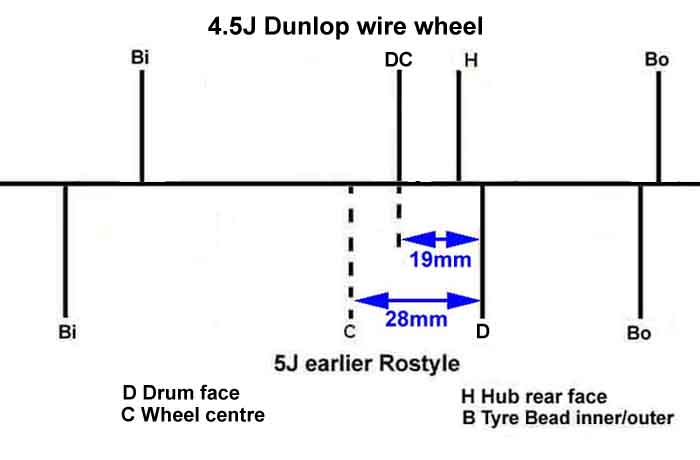

Comparison of my wire (aftermarket Dunlop India) and early Rostyle wheels. The drum faces are 19mm apart which is half the stated 1.5" difference in width between the two Salisbury axles. 28mm is the stated offset for the earlier 5J Rostyles I have i.e. the distance between the centre of the wheel and the rear of the hub/drum face. As measured on my Dunlop wire wheels there is 11mm between the rear of the hub face and the drum, and the centre of the wheel is 1mm inboard of that, giving an inset of 12mm. The Workshop Manual gives an identical track for both the roadster 4J disc (5J on the GT) and the 4.5J wire (roadster and GT) wheels, meaning that the different axle length was exactly balanced by the different offsets of the two wheels, and the centres of the wheels and tyres would be in the same place relative to each other. For the track to be the same for wires and Rostyles the centre of the wheel 'C' would have to be in the same place. But my rear track with wires is 20mm more than Rostyles or V8 alloys, indicating my wire wheels have 10mm less inset than the originals, implying the originals had 22mm inset, and the later ones with increased clearance to the arches would have even more. SC Parts have wire wheels for the MGB with 14, 19 and 22mm insets which is quite a range. Even though the wire wheel is a 4.5J compared to the 5J of the Rostyle the outer face of my wire wheels and hence the tyres are closer to the arch than with Rostyles, 10mm closer even than the wider tyres on the V8. That probably explains why I still have some rubbing with 175 tyres whereas people with original wheels say they do not.

Wheel and tyre width is irrelevant to track as that is measured from the centre of each tyre/wheel. The factory figures for front track are the same as the rear for wire wheels, but 1/4" less for disc wheels, indicating that the different hubs did not quite balance out the offset. If choosing wider wheels you would have to go for more offset to maintain the clearance to the outer arch on a chrome bumper car, while still giving adequate clearance to the inner part of the wheel well, which would have the side-effect of reducing the track. There should not be a problem with rubbing the outer arch on rubber bumper cars as the arch should ride up over the tyre on the inside wheel, which is the one that moves out on a corner.

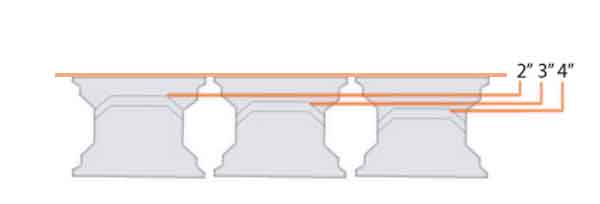

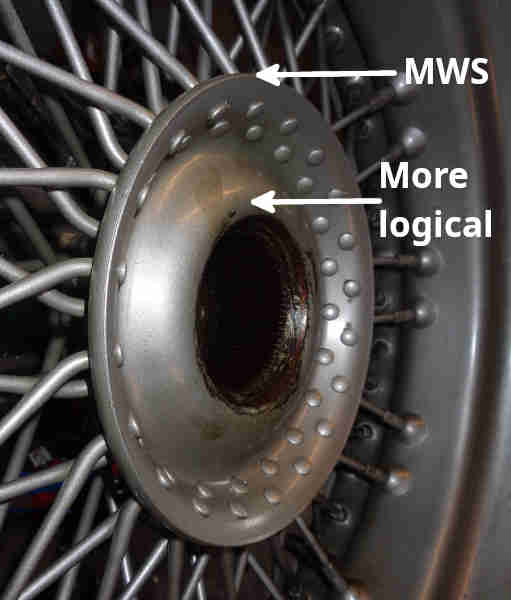

Showing the protrusion of the 'hub cap' mounting face of the earlier narrow-track wheel. This makes the wheel 'wobble' when that side is laid down on a flat surface with the hub-cap removed. The later wide-track wheel with less offset lies flat with no wobble.

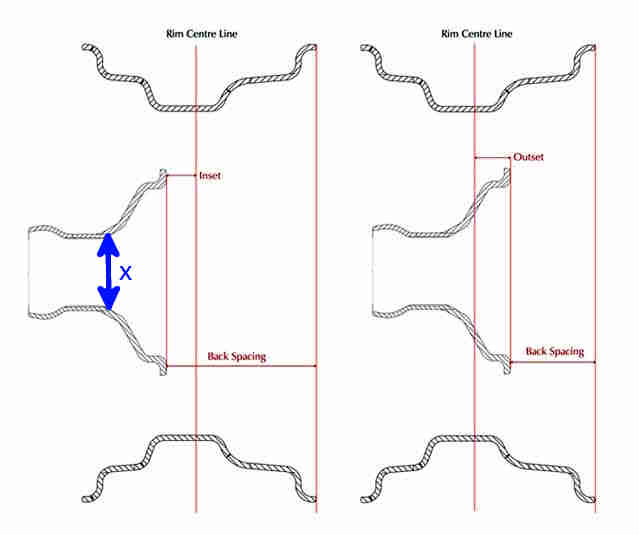

Stud Wheel Offset and Backspacing:

Positive, zero and negative offsets. Positive offset is the usual arrangement - for steel and alloy wheels at least and puts the centre of the wheel inboard of the brake drum mounting face, to bring the angle of the kin-pin and the centre-line of the tyre together at the road surface. Negative offset is often used on show cars to bring the wheels out, but it causes them to move back and fore as the wheel is turned instead of pivoting and can adversely affect handling. Image from Crankshaft Coalition.

Offset and other wheel dimensions, from The MG Experience

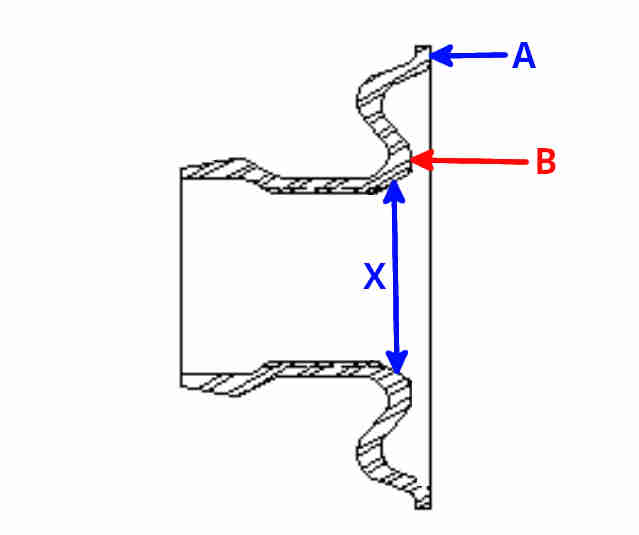

Stud wheel backspacing is the distance between the inner rim of the wheel and the mounting face to the hub, as shown here, taken from this site

This means there is a mathematical relationship between wheel width, offset and backspace, and it is much easier to measure backspacing and use the stated wheel width to calculate the offset, than measure the offset directly from some notional centre-point of the wheel. For positive offset wheels as on the MGB, take the backspace, subtract half the wheel width, and you have offset.

Well, I say easier, but it is not quite so simple as that. Backspace is measured from the outer edge of the rim so the wheel width has to be measured in the same way, you can't use the stated wheel width is that is from the outer edges of the tyre bead seat and is typically 1/2" or more less than the overall width.

Another complication if measuring existing wheels with tyres on. If you don't have a straight-edge that only sits on the rim and doesn't reach the tyre, you have to take into account the 'bulge' of the tyre past the rim. I laid a straight-edges across smooth parts of the tyre wall, and measured from there to the edge of the rim on each side to get two 'bulge' correction factors. Measured tyre bulge to tyre bulge and subtracted both correction factors to get an overall rim to rim width. Then I could do the original calculation for offset and got 28.5mm - close enough to the stated value of 28mm.

Wire Wheel Inset/Offset and Backspacing from MWS. Therefore inset on a wire wheel is the same as negative offset on a stud wheel, taken from the back of the hub, as is backspacing:

But that is a very simplistic drawing just showing what inset and outset are and the hub shape bears no relation to mine. The measurement points on the hub they show are miles away both radially and laterally from the mounting face 'X' and subject to any distortion where the spokes are. MGB hubs are 'folded back on themselves' as you move outwards from the mounting face and there is a much more logical place to take the measurement which is very close laterally and radially to the mounting face and away from the spokes:

Diagramatically as here adapted from this Dayton Wire Wheel drawing showing the MWS point at 'A', the mounting face at 'X', and the more logical measurement point at 'B':

Three of Ryan Frederickson's wheels have these stampings and 'Made in England', the odd one out has nothing. '4.5Jx14' is the wheel width and diameter, but what about the '14.3'? Clausager says that in Sep 76 there was a new wheel that has 9/16" inset i.e. 14.3mm , but why give that dimension in mm when the others are in inches and they could have put '0.56'? Also that wheel gives less clearance then the unmarked wheel, when Clausager say the change was to give more.

Mike Bennett's 'original' (his quotes), indicating a 21mm offset?:

Really you need to take a wheel such as either of the ones above with the '21' and '14.3' stamping and see where that puts you from the centre of the rim in relation to the mounting face of the rim and the 'folded back' edge.