Rocker cover nut with spacer, cup washer and rubber grommet 12A1358 added. There is almost 1/4" of the nut slicking through the grommet, this seems unnecessary if it isn't the intention that the cover nut should tighten down to the rocker gear nut to prevent crushing. And if my cover is distorted and that is why I can't get enough pressure on the cork gasket, it seems perverse not to have made the nut a bit longer to prevent distortion of the cover. But then I suppose, it would be at the mercy of grommet and cork gasket thickness ... The nut also shows signs of spreading at its lower (right-hand in the picture) end, presumably from some significant tightening once it had bottomed in the past:

When the cover nut is screwed down to the rocker gear nut there is 0.51" of the cylindrical part of the nut still above the cover. This is only a bit less than the thickness of the spacer, cup washer and grommet, which is why I can't get enough pressure on the cork gasket without one or more shims of gasket card under the cup-washer:

Stud proud of the rocker cover by five threads. One opinion has it that the top of the stud should be 1/4" below the face of the cover that the rubber washer sits on. This would imply that face should be level with a line drawn from the base of the filler tube, and the very top of the cover at the right end. This simply can't be the case as all Clausager's photos, for example, clearly show the rubber and cup washers sitting in a recess:

Some general views of the cover. One problem with only tightening to the recommended 4 ft lb is that unless you have a very slim spanner to hold the cover nut still, or add another narrow spacer under the heater pipe bracket, the whole thing can turn while tightening the heater pipe nut:

Slight bowing of the top which isn't really apparent until you squat down and squint over the top of the wing:

Also slight bowing at the end of the vertical channels. Again not that apparent (and not as much as might appear from the shading in the above photo), and as it's symmetrical i.e. at all four of them not obvious as a problem:

Comparison with a 1980 rocker cover, still two threads proud of the cover:

The same 1980 rocker cover, and still some bowing at the bottom of the vertical channels:

Conclusions? My gold cover is crushed, by about 3 threads going by the stud, and with only a little more bowing at the bottom of the vertical channels, but it doesn't seem different enough to be the only cause of the problem. However the 1980 cover nut does go down further than mine, and does apply sufficient pressure to the gasket, even with severely compressed grommets, without bottoming on the rocker gear nut.

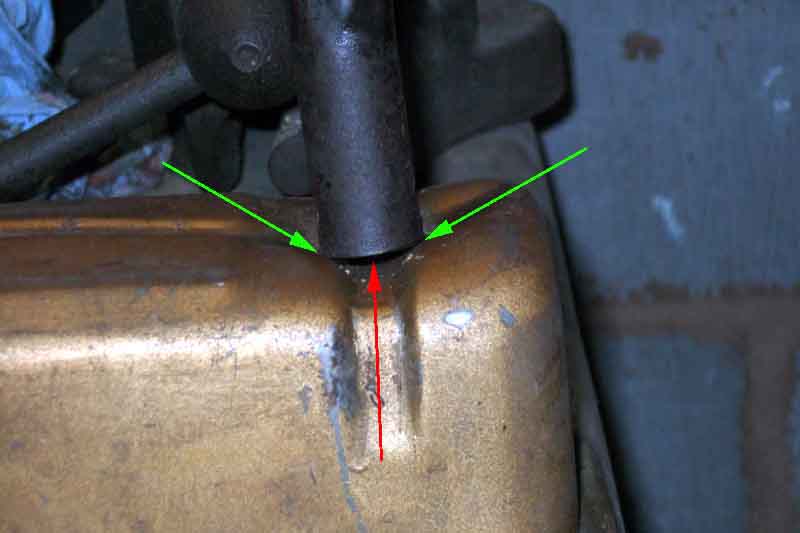

Subsequently during head gasket replacement I looked at the cover more closely. A socket placed where the grommet and cup washer goes shows the hole is badly distorted round the hole, touching at the green arrows, but a 3 or 4mm gap at the sides. Hence the constant small leaks down the side of the cover I'd always had:

Clamping the cover between a suitably-sized socket on the outside ...

... and a tommy-bar type plug spanner on the inside that just happened to have the perfect diameter as well as being long enough so the edges of the cover were clear of the vice jaw. Wiggling the cover back and fore sideways and top to bottom ...

... flattened the holes out nicely:

Gasket retainers spot-welded to the sides and ends of the pressed metal cover, that alloy covers don't have: