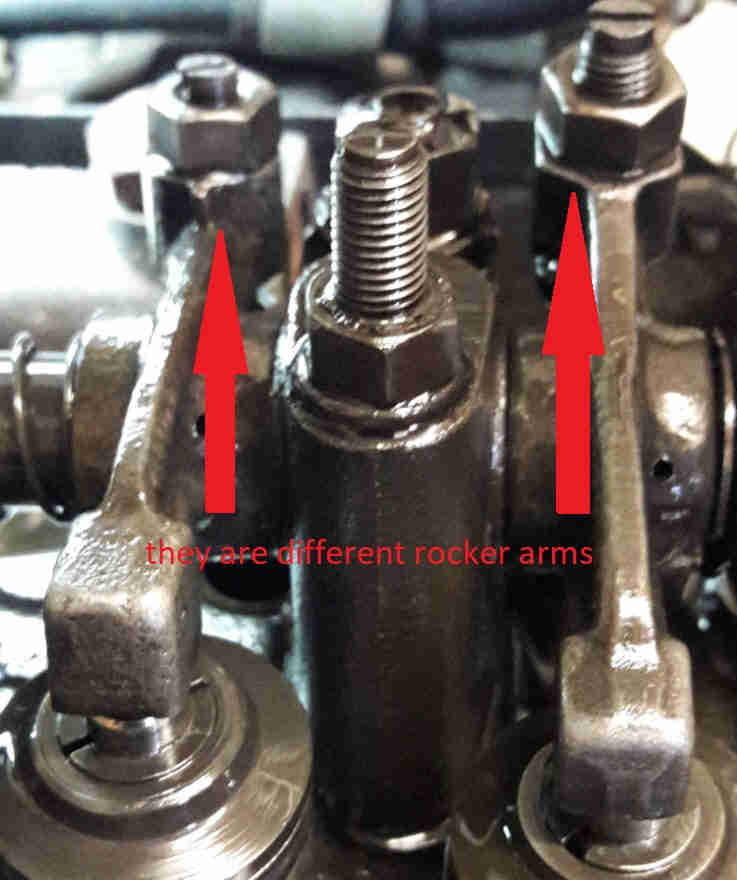

Showing No.2 rocker significantly misaligned wrt the valve stem, and a sliver of head machining showing (circled) which indicated to me the pedestal may have some scope for being pushed to the right.

After: Just enough movement available to completely cover the valve stem, and the head machining.

The threaded part of the rocker on the left extends above the rest of the arm by quite a bit more than the one on the right. Assuming that means there is that much more thread on the one on the left then the extra height will account for the lack of thread showing. Looking around the one on the right seems to be the norm for the MGB: (Jonathan Bawden amended by John Pinna)

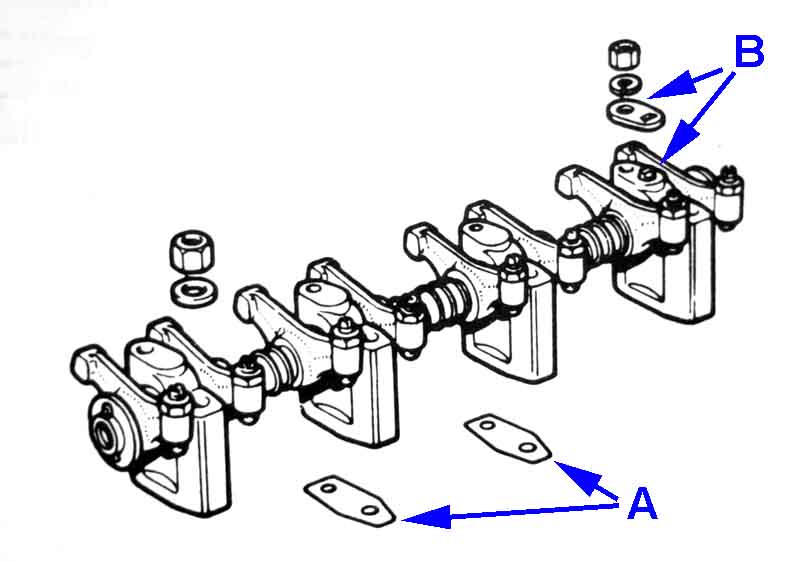

The 2 thou shims (A) under the middle pedestals as depicted in the Workshop Manual on later engines, which should be fitted to early engines on reassembly. The shims slightly misalign the centre pedestals wrt to outer ones, and when all four are tightened down the misalignment prevents the shaft from fretting in the pedestals. Also showing the locking screw and plate (B) that positions the shaft in the pedestals for oil flow out to the rockers. However as the screw has to be positioned so that it's tongue fits into the slot in the plate, it can only be in one of two rotational positions. This means that although the end of the screw when in the hole in the shaft will prevent the shaft turning by a significant amount, it is very unlikely to clamp it in position, which means the shaft may still be able to fidget in the pedestals causing wear and noise, hence the shims. They are NOT a reason to leave out the clamp screw and plate though as they also prevent oil leaking from the rocker shaft.

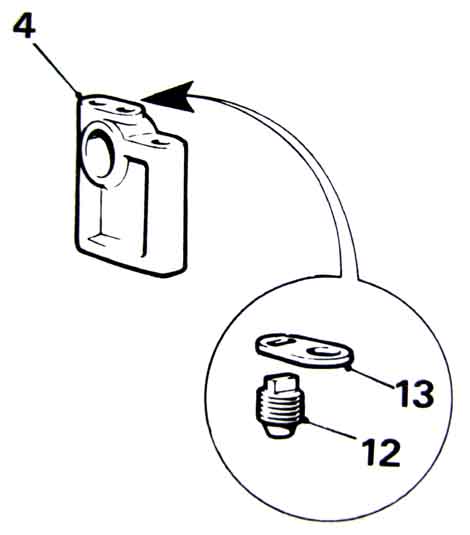

Detail of the locking screw and plate from the Workshop Manual. However when fitted the locking plate (13) is the other way round i.e. the screw goes in the centre hole of the pedestal with the slot in the plate over the tongue in the screw, and the hole in the plate by the edge of the pedestal.

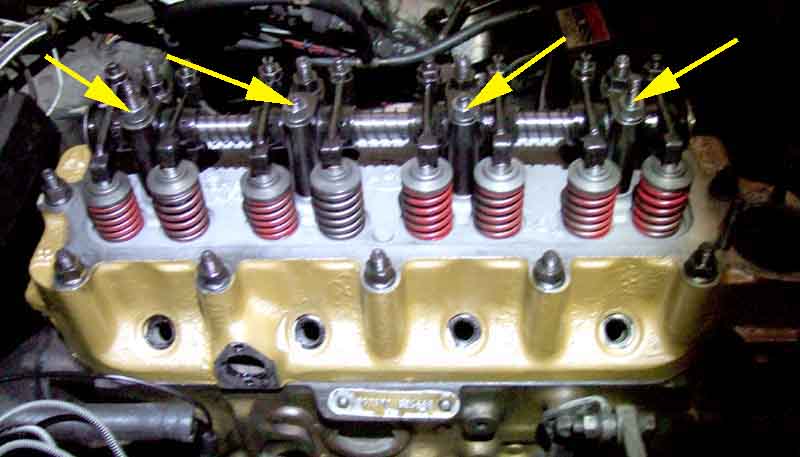

The indicated rocker pedestal nuts i.e. the ones closest to the valves can be removed if required without resorting to the cylinder head nut slackening/tightening sequence: