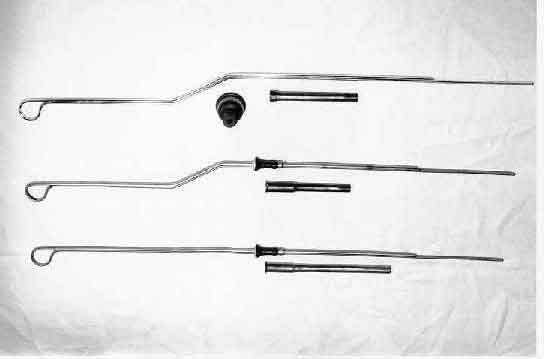

- 3 main-bearing: 1B1735, 18G/GA, sliding dust seal, no stop.

- 5 main-bearing: 12H74, 18GB to GF, sliding dust seal, no stop.

The stop on the middle and late sticks also acts as a seal for both dust and the vacuum created by the PCV systems. These were first introduced while the early stick was still being used, but if the sliding seal is pushed down to the top of the tube it would have the same effect. I've wondered if the stick resting on the sump floor could rattle, and eventually wear a hole through. But if the seal were slid down an inch or so before the stick was replaced, then the stick pushed down to the sump floor so lifting the seal to the correct position, when released the resilience of the seal may well lift the stick just clear of the sump, as well as ensuring a seal.

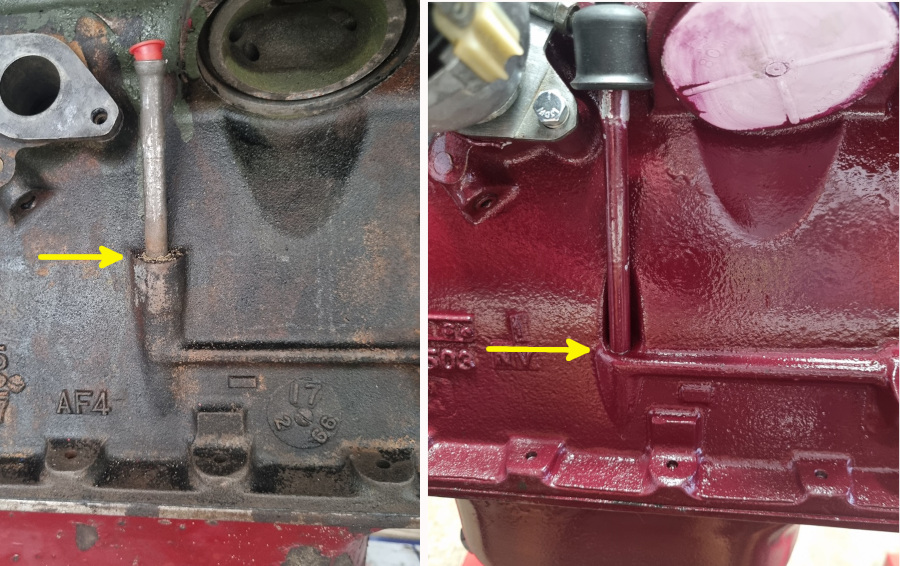

The reason for the different length tubes becomes clear in these pictures from Edouard Prioul - 18GB left with the entry hole for the tube in the block much higher than later blocks on the right. The tops of the two tubes are at the same height:

Early sumps had the plug forwards of the right rear corner, the dipstick rests on a raised portion of the sump (arrowed):

Here on the 18G/GA 12H395: (NTG Services)

After that the sump plug was on the right rear corner and there is a 'shelf' under the dipstick instead of a short raised portion, but the dipsticks don't touch it:

Originally sump plug washers were solid copper which some say have to be re-annealed at each oil change to prevent leaks, however I've never had one drip in 55 years on multiple cars ... until changing Geoff's oil on his 78. It was only when backing that off a few turns to wrap PTFE tape round that I noticed it was very thin and ragged. Then discovered replacement washers now are crush-washers - which Geoff's obviously is - and so must be replaced every time: (Rimmer Bros)

The part with the sump plug is cut away to access the torque converter bolts for the automatic gearbox via a hole in the engine back-plate, without removing the sump:

The auto was available as an option with Mk 2 cars but this style of sump may not have been available from the beginning as published information varies on what sump was used when. The Parts Catalogue only lists 12H395 for 3-bearing and 12H3541 for 5-bearing, Moss Europe lists 12H1976 for 18GB (5-bearing Mk1) to 18V797 (North America 1975 modal), and British Automotive states 12H1426 for 18GF, GH and GK i.e. Mk2 before the 18V, but I've not been able to find any detail on either of these. Clausager says a changed sump for the 18V797 "may have been introduced on North American engines from the start of the 18V836/837 series" i.e. the start of rubber bumpers. Oil capacity does not help as driver's handbook gives the change from the high volume to the lower with the 18V i.e. the 581 in August 71.

The access hole seems to have been deleted after the auto as more than one example of a later model doesn't have the plug, but the sump continued:

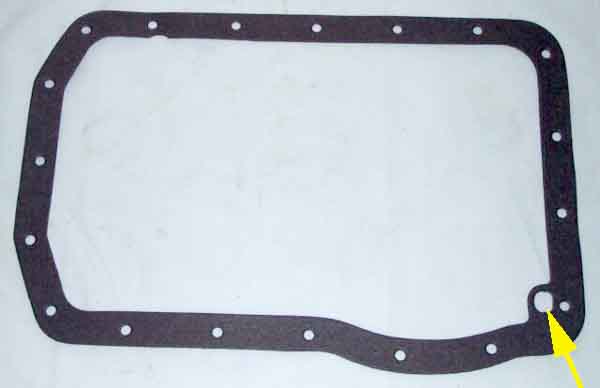

3-bearing gasket. The bolt pattern on the 3-bearing sump is different to that of the two (interchangeable) 5-bearing sumps - the 3-bearing has an extra bolt along the left-hand side which moves the front left-hand one (lower left in these images) round the corner a little way: (Chris at Octarine Services)

5-bearing sump. What is the purpose of the vertical 'tube' (arrowed) in the lower right-hand corner, with matching hole in the 3-bearing gasket?

There is a matching hole in the block right by one of the sump screws - overflow from the relief valve?

It appears to have a retaining nut that screws onto an adapter in the gearbox, similar to the oil-cooler hoses:

Showing the position of the dipstick in the sump: (Rover P5 Club)