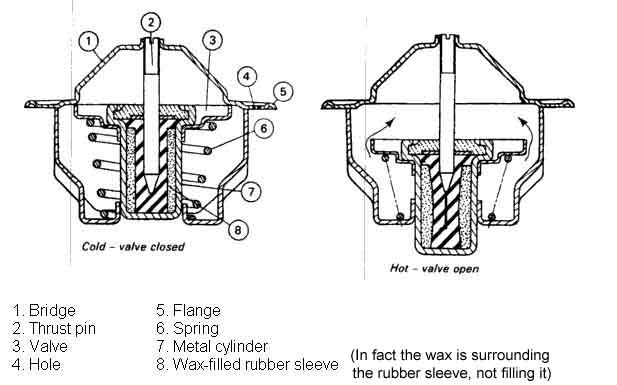

Typical wax-pellet stat:

Note: Some eBay suppliers are selling MGB thermostats accompanied by this picture:

Wikipedia describes this type thus:

Thermostats are rated at a given temperature - typically 82 in the case of the MGB - stamped on the bottom of the metal cylinder containing the wax pellet:

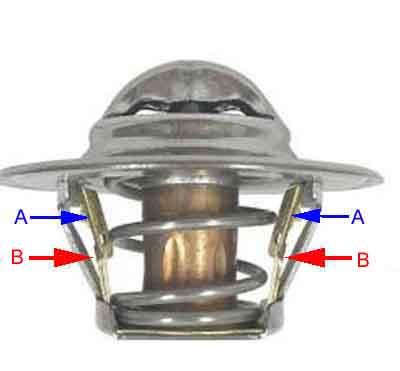

A typical latching stat. As the stat opens the disc pushes its way down the brass-coloured strips (A). If it opens far enough for the disc to reach the recesses (B), then the disc locks in that position, and even when the coolant temperature reduces it will stay there.

Typical Wahler thermostat and its 8 degree or so range from starting to open to fully open, and the 2 or 3 degrees difference between warming up and cooling down to reach a given partially open point. It is the ability to start closing when the temperature has dropped by only a couple of degrees that allows the thermostat to maintain a minimum coolant temperature (in most circumstances) with varying demand on the engine and changes in ambient temperature. The exception is in very cold conditions where surface cooling of the sump, block, and use of the heater may take so much heat out of the coolant it never gets hot enough to open the stat. Image from 'viva-lancia.com'.

A wax stat when cold (left) and hot (right). The metal cylinder containing the wax (7) is in the coolant that is being heated by the block and head i.e. below the valve (3) which is closed. As the wax is heated it expands, squeezing the rubber sleeve (8). At a given temperature this overcomes the pressure of the spring (6) and starts to push the thrust pin (2) out of the rubber sleeve. Because the top of the pin is attached to the bridge (1), which is part of the flange (5) which is clamped between the head and the thermostat cover, this movement actually causes the metal cylinder to move downwards, which pulls the valve (3) downwards. This open the valve and allows coolant under pump pressure to circulate via the radiator and initiate cooling. If the temperature of the coolant starts to drop below a certain point the wax starts to contract, and spring pressure forces the pin back into the rubber sleeve to start closing the valve. Image from Hillier's Fundamentals of Motor Vehicle Technology.

Filling/bleeding arrangements. Most stats of yore had a jiggle-pin in the fixed part as per the one on the left below, or the opening part. Originally I thought this was made of something that would float, and so allow maximum bleeding during filling but zero circulation during warm-up. However on a Wahler thermostat I have the jiggle-pin is metal - probably brass - and definitely does not float even when submerged in water. So this type will allow some coolant to circulate when warming-up, and the jiggle-pin (as its name implies) is there just to keep the hole clear. On the right is a cost-reduced version with no hole in the flange and hence no jiggle-pin, but a very small notch in the edge of the disc valve instead (circled).

Bee's original Wahler has the jiggle-pin in the opening part, but all-metal so does not float and can only be there to keep the hole open.

That was an 88C, but although I changed it for an 82C I didn't notice any difference on the temp gauge until I had found the real problem for coolant loss and oscillation, which was headgasket failure.

A replacement thermostat has no visible notch or hole, but water placed in the upper part i.e. above the moving valve does slowly trickle through. Whether this is by design and a concealed aperture or an imperfect seal I don't know, but it was such a small aperture that it only allowed me to get a few litres of coolant in when filling from cold i.e. causing a massive air-lock under the stat, so I had to drill a hole in the flange.

The bypass-port in the head. It lies just below the resting place for the thermostat, and you can see that when the original MGA stat's sleeve (see below) rose up it would cover this port. Note also the drilled passage inside the port leading down into the block (arrowed).

This is the OE Smith's thermostat for the MGA. Note the moving sleeve around the outside of the lower portion. This sleeve blocks off the bypass port in the head once the engine has warmed and the stat has opened. Photo: Neil Cotty, from Bob Muenchausen's 'MGB Engine Cooling' page.

A blanking sleeve from Moss Motors suitable for the MGA, MGB and Sprite/Midget.

Standard MGB stat modified to become a restrictor by cutting the lower part of the frame off and removing the wax pellet with valve, and the thrust pin from the bridge:

At a pinch you can achieve much the same thing by removing the spring (hook one end outside the frame then 'unscrew' it) and manually pushing the valve open:

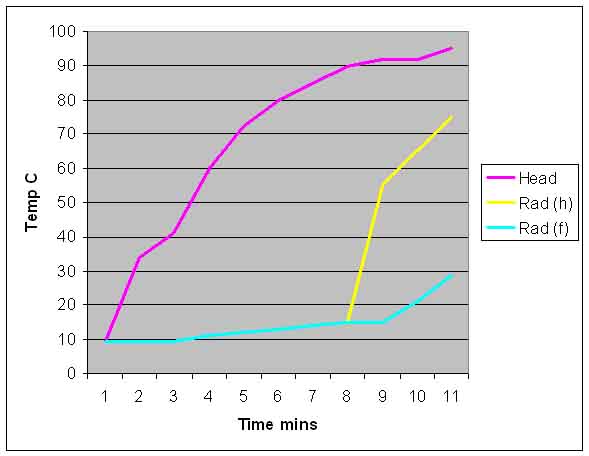

Typical temperature gradients for the head and the radiator inlet (Rad (h)) and outlet (Rad (F)) during warm-up, working thermostat fitted. With no stat, or a stuck open one, the first two lines would be close and parallel, but flatter taking much longer to reach working temperature. With a stuck closed stat the head line would continue to rise and the rad line would stay very low until the coolant (in the engine) reached boiling point.