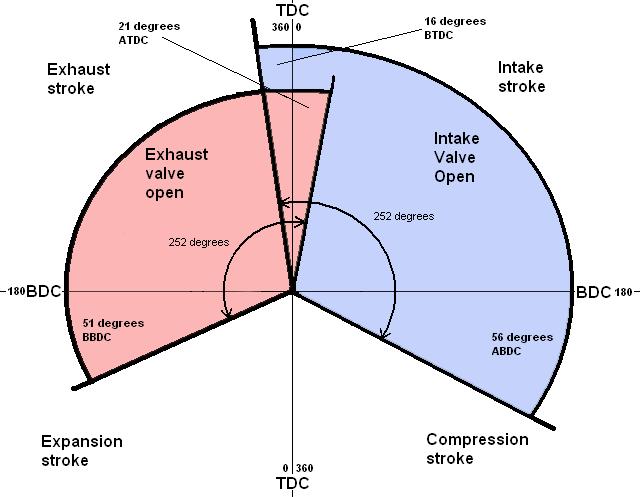

Valve operation over two full turns of the crankshaft as to me that makes it easier to understand the timing and overlap:

Valve adjustment methods:

Don't do each valve in order or you will be turning the engine much more than you need to. As soon as you have adjusted one start turning and look for the next valve that will be fully down and adjust its partner, and so on.

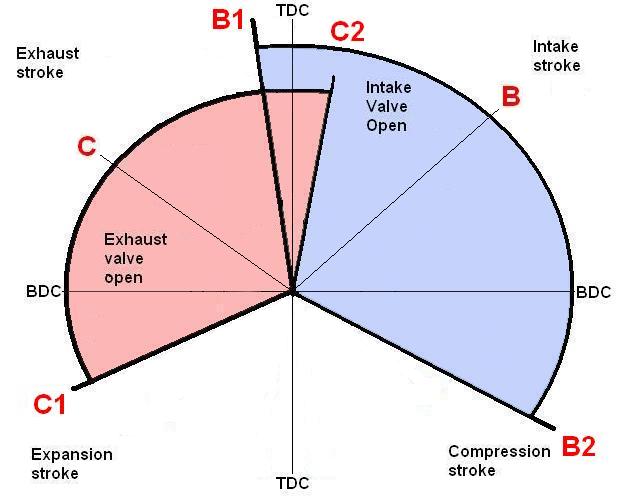

But in theory you can adjust them anywhere from B1 to B2, and C1 to C2, i.e. anywhere the partner valve is open even partially, which means that the RON method is effectively a 'rocking' method. So perhaps the definition of RON should be 'anywhere the partner valve is moving', instead of 'when the partner valve is fully down':

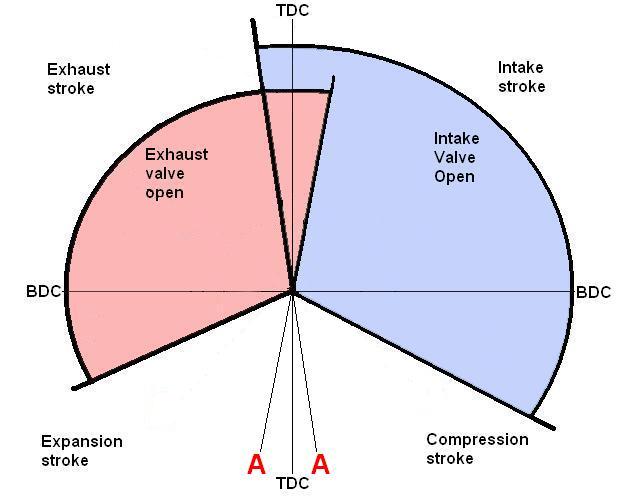

With the 'rocking' method if you set one cylinder so that both valves are partly down i.e. at TDC on the exhaust stroke, you can adjust both valves on the partner cylinder (1 and 4, 2 and 3) within the range A-A:

This effectively makes it a 'rule of five' method and needs three half-turns of the engine from the first adjustment position to complete all eight valves.

Adjust four valves in one go: But this 'rocking' method also allows you to adjust four valves at a time, which means you only have to turn the crank one full revolution from the first adjustment position to the second to complete all eight valves:

But none of these methods will work if you have a cam where the back of the lobe is not a true circle, as mine is and others have been found to be, which means the gap can be changing when it should be static, which makes getting the correct gap difficult. In that case all you can do is look for the point of biggest gap on each valve and adjust it there. Make a note of where other valves are in terms of how far up or down they are to help you locate the same position next time.