The canted over Mk2 version BHA 4667, not needed with the single-circuit brake master ...

... or the later dual-circuit master: (Steve Shoyer)

... but definitely was with the early North American dual-circuit: (Dave's Cars)

AAU7152 with the two concentric rings indicated on the cylinder body on the mounting flange side. The other arrow is indicating another mark like a letter 'O', which seems to be an alternative identifier, not additional. The internals of this type are different to the previous two, something you need to be aware of when buying repair kits: (Moss Europe).

GMC 1007 which at one time was the only 4-cylinder replacement. Several vendors show this plastic reservoir type: (Sussex Classic Cars)

But as of August 2015 both Motaclan/Leacy and Brown & Gammons have confirmed that they have the recently remanufactured original metal can reservoir type (not far short of double the price of the plastic reservoir type):

Is this the one that causes problems with the unboosted dual-circuit master? Whilst the main casting and the diameter of the reservoir seem to be much the same as for GMC1007, the cap is obviously much bigger: (Image from Victoria British)

This cylinder had a leak from between the reservoir and the casting which could have the upper wire clip above the casting and so tending to distort the plastic reservoir rather than seal it: (Richard Massey)

A previously failed master showing the position of an O-ring seal in relation to the top of the casting. Not much scope to get the upper wire above the O-ring but still on the casting: (Richard Massey)

This one from Rimmers seems to have both clip wires in the right place:

But this one from MSC seems to have the upper wire very close to the top and the lower wire may not even be on the plastic reservoir:

Yet another variant, this time with a fully cast body but a large plastic cap, pictured by several vendors. It's interesting to note that the cap states "Use only DOT3 fluid"! (Image from URO Parts ('Euro', geddit?))

Original GMC 1011 for the factory V8 and also some Midgets as pictured by Motaclan/Leacy but no longer available. Note the single groove round the cylinder near the mounting flange as on both V8 masters, not the two in the Moss Europe drawing above:

Current-stock GMC 1011 for the factory V8 and also some Midgets from Brown & Gammons:

Modification to turn the reservoir round and make the cap more accessible, but not trivial: (V8 Register)

GMC1011 installed on Hans Duinhoven's MGB, although it's a 4-cylinder so should have the GMC1007. Hans says there is enough room to access the cap even though it is an LHD where there should be less clearance to the bulkhead for the clutch master cap than it would have on an RHD. Originally the V8 master was 1.2mm smaller bore than the 4-cylinder, which with a 4-cylinder slave would give a slightly lighter pedal but less throw, i.e. the biting point would be a bit nearer the floor if the remainder of the mechanical linkage at the master remains the same:

Pal has one fitted to his 78 by a PO and the cap has had a section cut out and it has to be lifted up to be removed and pressed back down to fit:

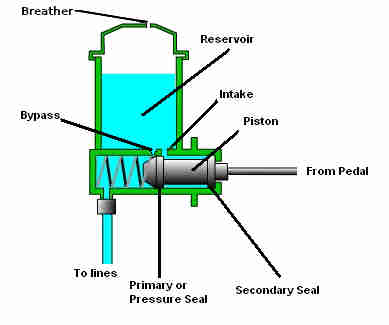

Showing how at rest fluid can flow from the reservoir into the cylinder in front of the pressure seal and from there down to the slave, and into the space between the two seals via the Intake port. When operating the pedal the primary seal has to move past the bypass port before any pressure is applied to the fluid. It also shows that at rest the primary seal has to come back past the bypass port to allow fluid expansion and contraction to pass in and out of the reservoir during temperature changes. If this doesn't happen and the fluid expands, pressure will be applied to the release bearing which could cause the clutch to slip and will definitely accelerate wear, as well as rendering it impossible to bleed:

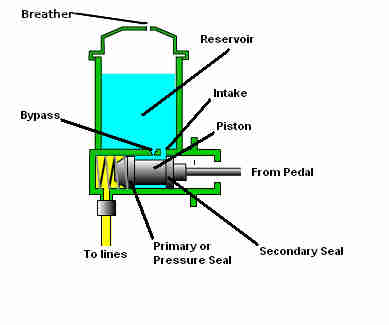

Showing how fluid fills the space between the two seals when the pedal is operated. If the secondary seal (nearest the pedal fulcrum) leaks you will get fluid running down the pedal, but the clutch otherwise operates normally (until all the fluid is lost!):

The Intake and Bypass ports, the brake master has the same arrangement:

The Bypass port is tiny:

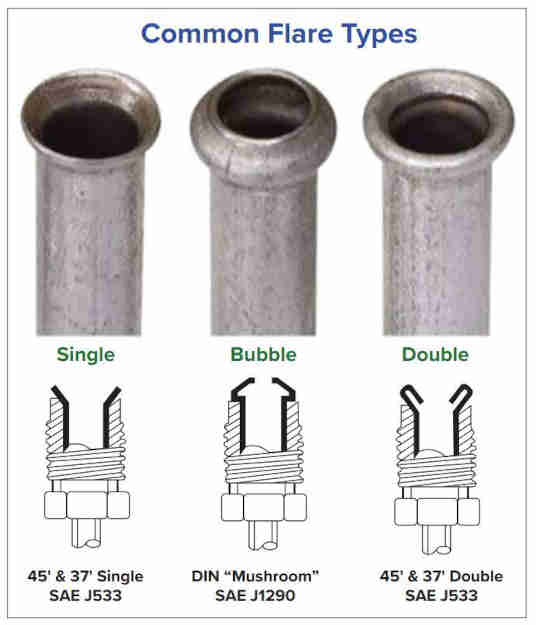

Pipe Flares: Three typical flares - with different angles available for single and double. Note that the bubble is like an incomplete double. A kind of 'double-bubble ...:

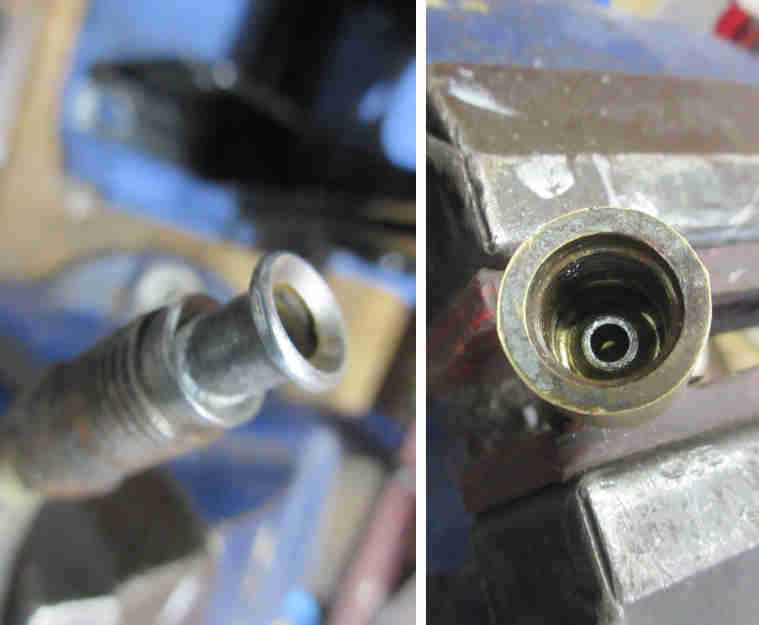

Clutch master - the pipe widens out towards the open end (this may be a double flare) so the centre of the banjo narrows as it comes towards you: (Brendan H)

Brake master - pipe has a bubble flare so the centre of the banjo narrows as it moves away from you: (Brendan H)