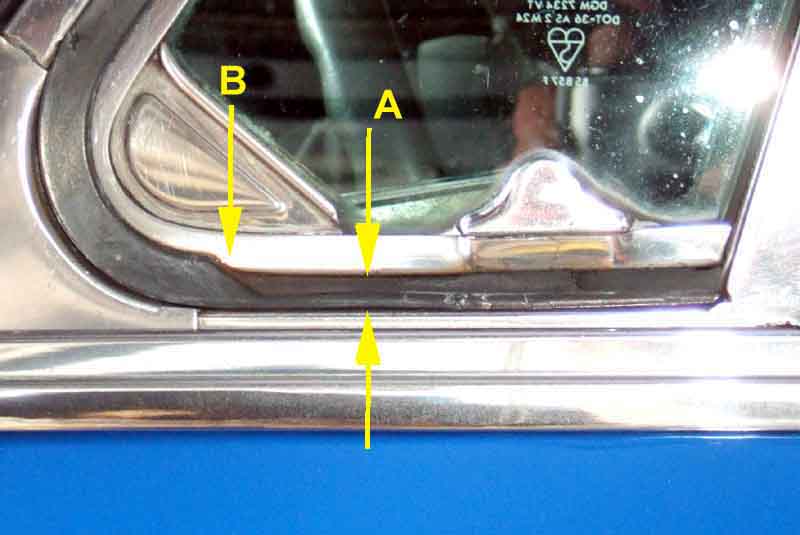

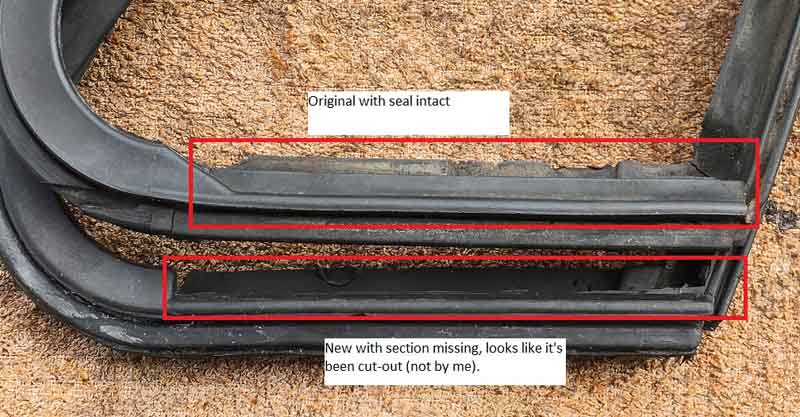

Roadster vs GT: Roadster QLs sit on top of the door on a short rubber gasket AHH7478 (RH) AHH7479 (LH):

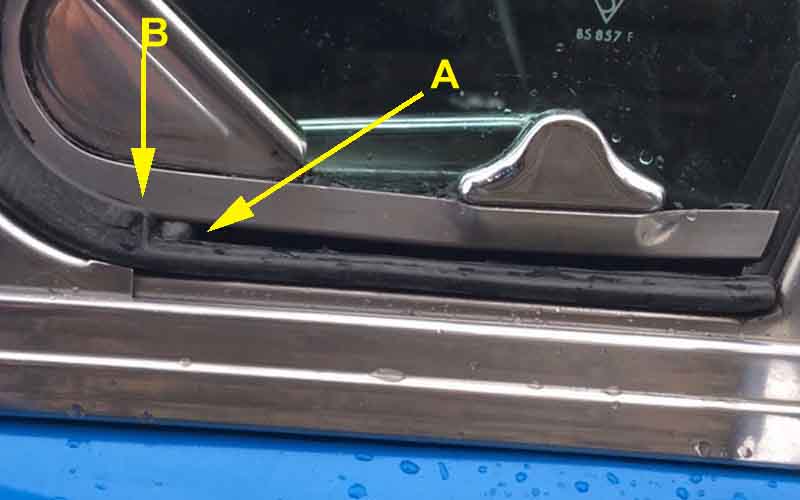

GT QLs also sit on top of the door but behind a full-length finisher AHH7476 (RH) AHH7477 (LH). This finisher carries the outer rubber 'scraper' seal for the drop-glass:

The reason for the GT finisher is that the roof-line of the GT is a good inch higher than the roadster, which means the GT drop-glass has to be taller as well (as is the quarter-light). But there is no more space at the bottom of the door for the glass to retract into, so the additional height is left sticking above the top of the door when wound fully down. Not a good look, hence the finisher to cover the additional height.

The screw securing the triangular finisher at the lower front corner of the QL is behind the trim-strip at the top of the door on the GT, visible above the rubber seal on the roadster. Only listed for the roadster in the Leyland Parts Catalogue, the same screw is also used on the GT. Despite that the trim-strip is flat against the finisher on Vee:

Graham Moore said his screw was too big and left a gap, and looking at suppliers catalogues Moss shows two alternatives only one of which is correct, and Brown & Gammons list the incorrect screw. It should be 17H2503 which is a self-tapper with a very low profile head with integral washer:

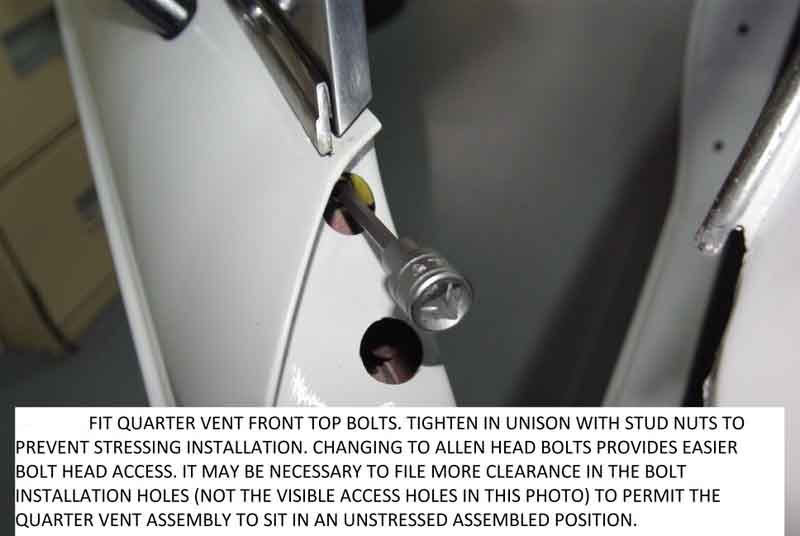

Remove/refit by John Maguire in Australia:

Hinges

Vent Seal

Glazing Seal

The vent handles were originally curved (AFH6532 RH AFH6533 LH) changing on Mk2 cars to straight (AHH8446 RH AHH8447 LH) as here. They are retained by locking pin AHA7474 (most easily seen with the handle fully in the open position) which can be driven all the way through to release the handle:

Brown and Gammons confuses things further by showing the earlier GT item and without the rectangular plate at the top! I suspect that has just broken off and they didn't notice ...

A length of brass tube (spacer/distance tube 17H2518) goes over the pivot with the vent in the frame, under the spring:

35 years ago it didn't seem to be listed by the usual suspects so I got two lengths of brass tubing from Bob's Models. What remains after making four roadster tubes is 10", so originally they must have been about 14". One has an OD of 0.31" and an ID of 0.285", the other has an OD of 0.28" and an ID of 0.245":

This means one fits inside the other really snugly, and the overall OD and ID are very close to the original:

Assembled with spring AHA7544 with plain washers GHF300 either side and Nyloc nut GHF221 (1/4" x 1/2"). A couple of sources give PWZ204 and PXZ305 for the washers but the former are 1/4" by 3/4" which seems much too big to me, it only needs to be slightly bigger than the spring dia otherwise it won't go through the top of the door. The latter are even bigger at 7/8":

| Roadster | Lower (frame, socket) | Chrome Q/L | RH | 17H2498 |

| LH | 17H2499 | |||

| Stainless Q/L | RH | BHH708 | ||

| LH | BHH709 | |||

| Upper (vent, pin) | Both | RH | 17H2509 | |

| LH | 17H2510 | |||

| GT | Lower (frame, socket) | Chrome Q/L | RH | AHH7696 |

| LH | AHH7697 | |||

| Stainless Q/L | RH | BHH775 | ||

| LH | BHH776 | |||

| Upper (vent, pin) | Both | RH | AHH7694 | |

| LH | AHH7695 |

Notes:

- All hinges are cast and chromed including those for stainless frames.

- The Leyland Parts Catalogue lists screw 17H2500 for roadster and GT frame/socket halves, rivet 17H2511 for the roadster vent/pin half and screw 17H2511 for the GT vent/pin half, but suppliers list screw 17H2500 for both frame/socket halves and rivet AHA9999 for both vent/pin halves. A pal's chrome frames did use screws, but my 73 roadster and 75 V8 GT (both stainless) have rivets in both frame and vent, albeit different ones for the vent to the frame.

- To fit/replace the correct blind rivets it maybe that the vent can be opened and the seal for that pulled out of the way for the frame rivets, otherwise the Q/L will need to be removed from the door and dismantled, and that will need to be done for the vent rivets in any event as the glass and glazing seal has to be removed. After scrotes levered one of my V8 Q/Ls open and broke the vent hinge I opted to drill out the original rivets with the vent in-situ and use pop-rivets for the new hinge. Not ideal, but barely visible regardless of whether the vent is open or shut. I did use the correct rivets when replacing the broken hinges on my pal's chrome Q/Ls. At that time (2013) some of the parts weren't listed for the MGB by Moss but were for other models, and other suppliers had different and incorrect parts listed for the MGB so care is needed.

Vent Seals AHH7435 and AHH7436:

Vee and Bee: 'A' - seal fills gap (about 7.5mm); 'B' - angled cut covering pivot (not that it would be visible anyway with no gap):

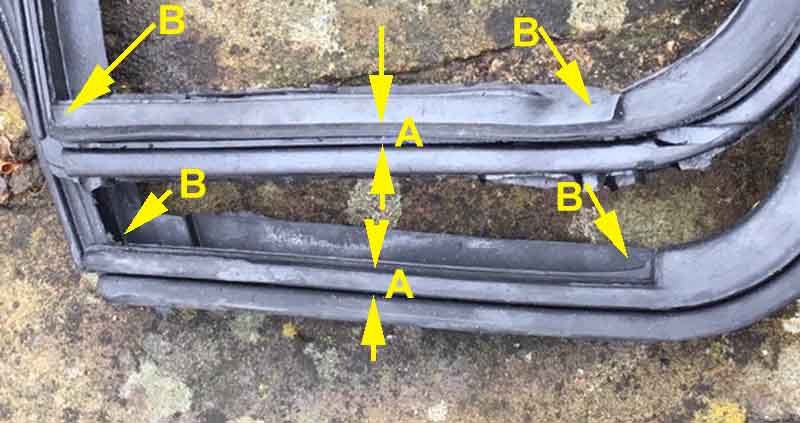

Top: Rimmers, Bottom: MGOC. 'A' - Rimmers seal noticeably narrower between QL frame and vent than MGOC. 'B' - Rimmers doesn't seem to be cut away by the pivot, a thinner section extends all the way across. It's possible that this folds flat as the vent is closed, covering the pivot even though the main section filling the gap is narrower: (Shaun Loader)

More examples from Albert Ross. The incorrect seals were from MGB Hive (no surprises there) and the MGOC. Rimmers (at the time) again had the correct profile:

When the vent is open the front part below the pivot opens inwards and the part above the pivot opens outwards. When it is closed the side of the frame lies against an outside flap below the pivot, and against an inside flap above the pivot to form a seal. There is a rib between the two angled downwards from inside to outside that the front of the opening vent frame sits against to complete the seal. In the attached from Richard Massey the upper, inner flap doesn't come down far enough and so leaves a gap when the vent is closed, circled:

Without looking more closely than I can see with a picture from a web site I'm not sure that that the Rimmer's item doesn't have Richard's problem, even though it has the correct profile along the bottom:

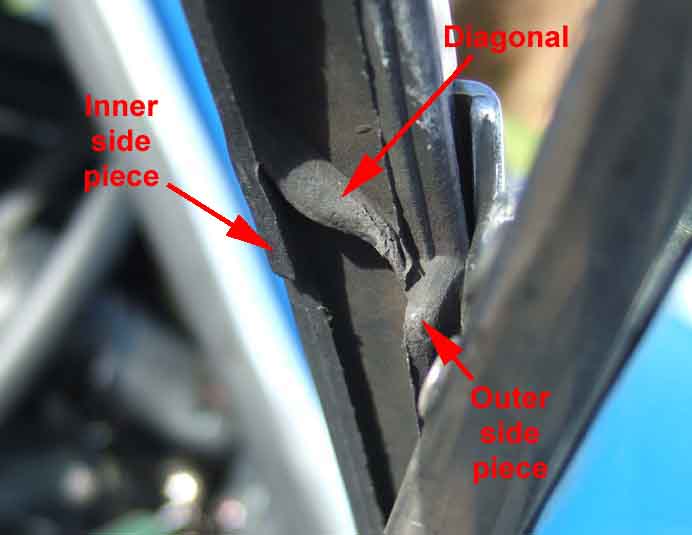

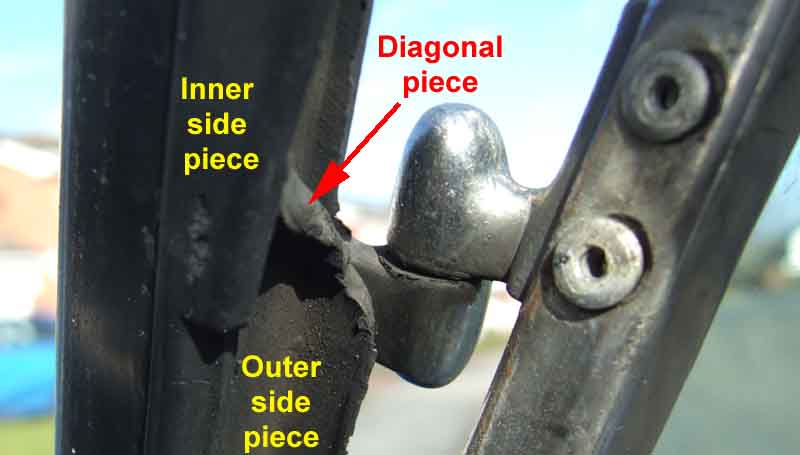

Vee's 'old' and quite possibly original seal with a pronounced diagonal angled downwards from inside to outside. The front face of the vent frame at the rivets presses down on this, and joins the top of the outer side piece. This means that water will run away to the outside. The inner side piece comes down to about level with the outer, but it probably doesn't need to come much further than the top of the diagonal. From the outside:

And from the inside:

My concern with this was that how to squeeze all the rubber into the bends, especially the lower corner which turns through more than 90 degrees, once the seal is folded into the channel, so I cut darts when doing both mine and Terry's. However this from Richard shows that by far the bulk of the rubber is trimmed off afterwards, so only a relatively small amount has to be squashed in to the corners:

Note the seal wraps around the rain channel at the lower front corner of the glass as well as round the glass. This channel extends beyond the pivot, so any water on the part of the glass that is brought inside the cabin when the vent is open is directed outside.

Brown & Gammons U-channel vent glazing seal - still has to go round two corners though and has been said to be too thick:

These seals (flat and U-channel) are also shown for use at the bottom of the drop-glass.

Ben Colomb's vent seal, obviously a moulded seal way too long for this application and so almost certainly for the GT rear windows, which although perhaps easier to fit leaves a gap behind the handle plate. This shows the rain channel on the outside of the glazing seal, which is not correct, although what practical difference it makes I don't know:

A partially dismantled rear quarter-light showing how the seal is nowhere near as deep as the channel, so as this channel is almost twice as deep as the front vent the rear seal could well be a reasonable fit in the front vent: (Sven Hinrichsen)

Rear quarter-light seal BHH582: (Moss Europe)

I did wonder if the base of the seal might be thicker than the flat strip, but it seems unlikely, The sides of the moulded strip are thicker than the flat seal would be, but as the two channels are the same width that's unlikely to cause a problem either: (Moss Europe)

Bottom stud plate corroded away on one of them:

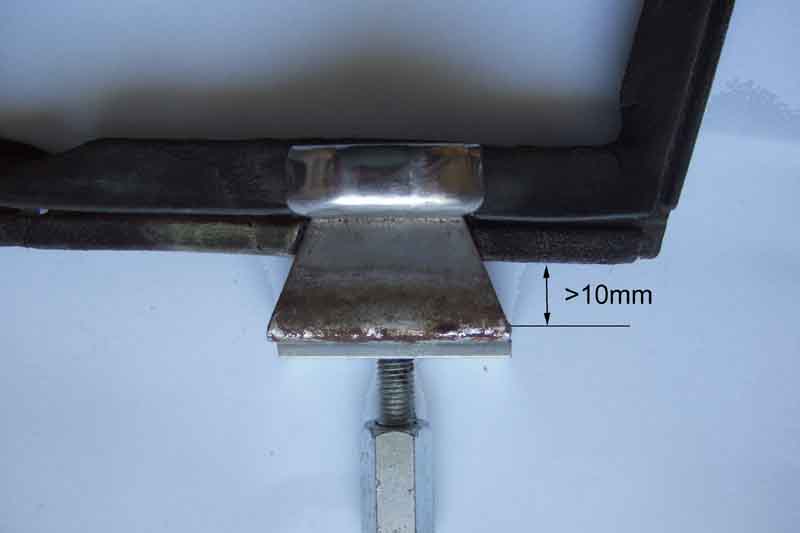

As a result of a question by C Cummins on the MGOC forum, note that unlike the chrome frames above, stainless frames have the bottom stud plate pop-riveted to the side of the leg and wrapping round to the front, on both roadster and GT, instead of being riveted to the front. Also the front face of the channel is flat, and not recessed as on the chrome, so this stud plate has a double-bend to position the stud in the same place as before. Although shown detached I'm not aware they are available separately, this picture is from an eBay ad for remanufactured units. Maybe they make them, and would supply them ...

Some pitting on the handle brackets ...

... only light pitting elsewhere:

Countersunk slotted screws on the opening vents, rivets to the frames on chromed units ...

... both riveted on the later stainless units. Replacement hinge pop-riveted on Vee rather than have the job of removing and replacing the glass from the vent frame:

Replacement stud plates with 2BA threaded holes:

Reinforcement plates for the above stud plates. These go inside the door, short one to the front, with the hole nearest the front: Images from Motaclan/Leacy

Plenty of clearance for nuts on top of the latch plate:

Fully dismantled and ready for the rechromer:

Bottom stud repair on the right. The light rusting is on one side only, to be treated along with the other one before return to Terry:

Parts as returned, the other one is just the same:

Final assembly, again the other one is just the same:

What an innocent-looking little thing that pesky hinge is: