Clutch and brake master cylinder repair kits are confusing for several reasons:

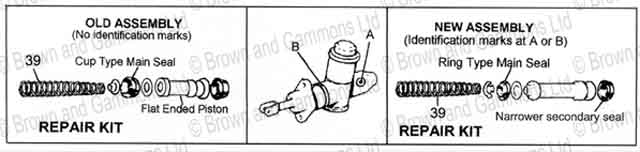

- There were two different types of internals, changing "sometime in 1973" (Clausager), but any car could have either now:

- Early brake and clutch masters had one cup-type seal (the pressure seal) and one ring-type seal (the secondary seal).

- Later brake and clutch masters have two ring-type seals.

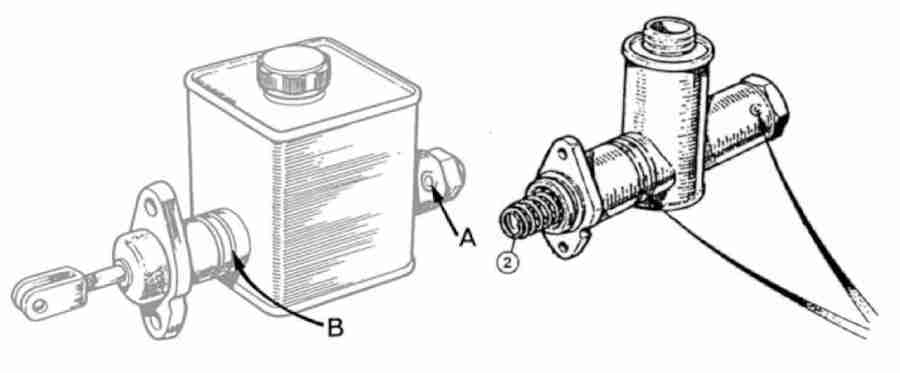

There are identification marks on the later masters originally fitted with ring seals but supplier information is confusing if not incorrect as here from Moss. This shows two grooves around the bore by the flange and a smaller symbol (two concentric rings) by the banjo:

This from Brown & Gammons could be showing the same but isn't clear enough to see if there are one or two grooves by the flange:

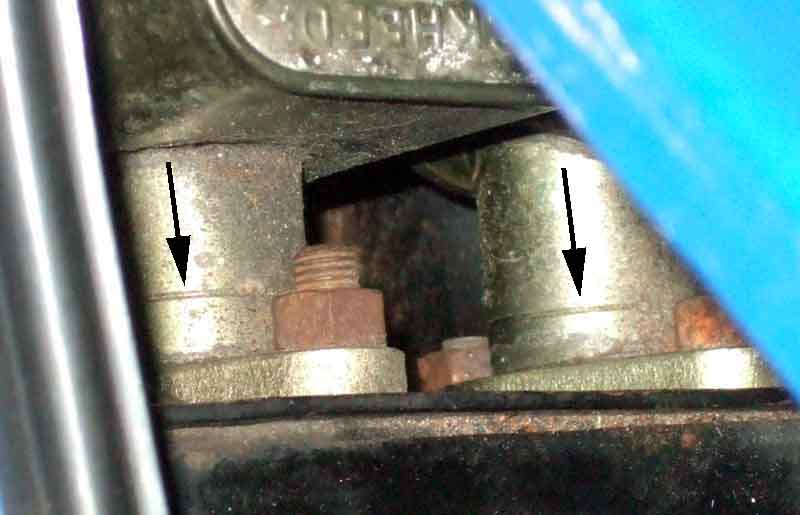

Both masters on my 75 V8 have a single groove by the mounting flange:

Groove barely visible on the replaced brake master on my 73, the clutch master is the earlier cup-seal type so no markings:

To get the correct seal kit for your master you would need to remove the existing piston first to see what seals are present, or you could go straight for the conversion kit albeit wasting money if you already have the later or already converted master.

But there is another factor and that concerns the seal spreader inside the cup seal, which none of the seal kits show. I had the clutch master seal leaking back on Bee so the clutch would slowly engage while I held the pedal down, and on removal of the piston and seal I could tell that the seal had been cocked to one side because the spreader had broken, but fortunately I had kept an old master and reused the spreader from that. Otherwise I'd would have to go for the conversion kit.

Cup-type seal internals: The shim (arrowed) goes between the seal and the piston, and on all pistons both primary and secondary seals face forwards. When fitting the dust cover to the push-rod do so from the piston end before assembly to the master cylinder, the sharp edges and large size of the clevis pin fork can rip the seal:

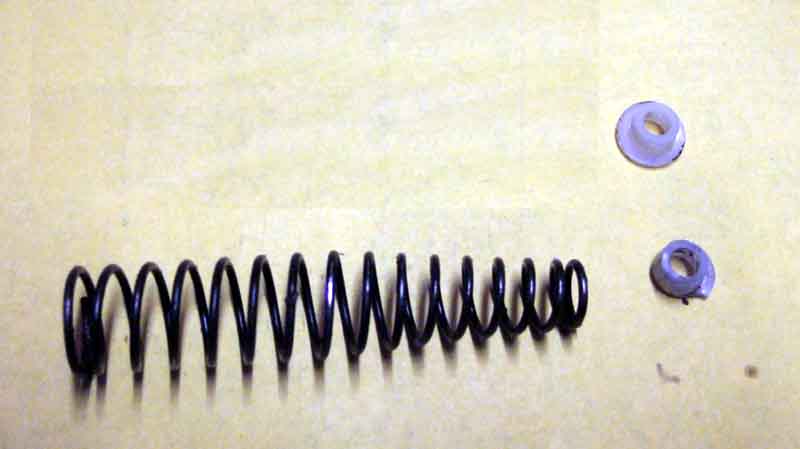

Bee's broken clutch seal spreader that came out (bottom) and a good one from an old cylinder (top):

The spreader does not appear to be available meaning if this is broken or lost the ring-seal conversion kit would have to be fitted.

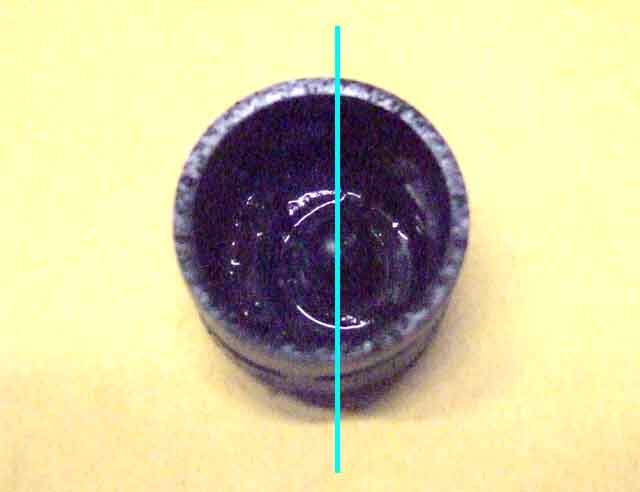

The distorted seal. The vertical line runs through the centre of the pip that is at the bottom of the cup and sits in the hole in the spreader. That should be central, but is clearly displaced to the right because of the broken spreader:

A selection of pistons and seals: A is the new piston from the conversion kit, B an identical item from a previously changed cylinder. C is from the V8 clutch and has two parallel rings! D is probably from the roadster brake master and identical to the one from the clutch master:

The cup-type seal removed from Bee's clutch (A) significantly longer than a similar seal from another cylinder (B). If the replacement seal is like B, that would explain why the biting point is now lower. (It wasn't, that turned out to be a problem with the release arm and bearing alignment with the cover plate):

Piston and cup-type seal from Bee's clutch (A) significantly longer than the piston and ring-type seal of the conversion kit:

Three from Richard Massey on the MGOC forum - top from a 100 mile no-name plastic-bodied replacement that started leaking, middle from an older TRW plastic, bottom from a metal can. Slight differences in thickness of the flanges either side of the seals which is irrelevant as long as the seals are in the same position. Also slight differences in diameter of the flanges but only 3 thou max between any of them. Speculation that it was deliberate to give greater clearance to the bore, but I can't see that after all these decades, and it would allow for more lateral movement of the piston in the bore which could impact the sealing. Whilst my old pistons do show some polishing on the sides of the flanges there was no scratching or scoring in the bore which the 100 miler shows. What (to me) is more interesting is the long extension inside the spring of the no-name plastic. It shows how much free space there is at the bottom of the cylinder, and I can see it being needed in some applications to prevent the piston going too far and tangling up the spring, which then may not push the piston back as it should when the pedal is released. Neither do you want to push the secondary seal past the inlet port which will cause fluid to leak out: