Speedo Fitting: May 2021

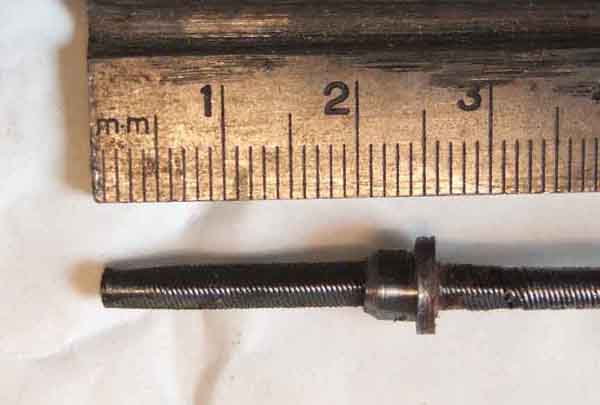

Prior to the 77 model year the inner projects about 10mm and the ferrule sits against the end of the outer flange:

Whereas for 77 although the ferrule is 20mm along the inner it also sits inside the outer by about 10mm, so projects by about the same 10mm:

If the inner goes to the end of the square hole in the pinion gear at the gearbox end then it may project further from the outer at the speedo end.

Using the longer 77 and later inner as a 'depth gauge' in a pre-77 speedo you can see that there is about 13mm of depth available inside the speedo fitting. If the inner projects further than that - for example using a 77 and latter inner on an earlier speedo, the inner would be pushing the input shaft into the speedo with some force as the knurled nut on the outer was tightened, which would almost certainly affect speedo operation. That would be an extreme case, but if slackening the knurled nut cures the problem it would be worth checking the amount of engagement:

Incidentally leaving the knurled nut loose is not a good idea as the outer will not be square to the speedo, the inner will enter the input shaft at an angle and may eventually break.

Another potential problem concerns the ferrule in the end of the inner. In the pre-77 cable it projects past the flange on the outer by less than 1mm, and that has to be accommodated inside the speedo fitting or the ferrule will be pushing against the input shaft when the knurled nut is tightened, even though there may be enough clearance for the inner itself. On the corresponding speedo the input shaft is recessed by about 2.5mm, so more than enough:

On the 77 and later cable the ferrule sits down inside the outer so that is not an issue. On a pre-77 speedo the square hole in the shaft is recessed by about 3-5mm, meaning there is about 5-7mm of inner engaged with the square hole in the speedo shaft. That should be more than enough as long as the nut at the speedo end of the cable is screwed fully on and the outer is held firmly.

Replacement: March 2020

I get the speedo out of the dash in about five minutes (only one clamp but I've never been aware of it not fitting the dash correctly) and can pull it forwards far enough to unscrew the cable from the speedo, and remove the illumination bulb. The trip odometer reset is a long cable that fits unto a bracket behind the dash, so that has to be undone as well. I can twiddle the inner while fully inserted so it's definitely a problem 'down there' and not with the speedo. I can pull 68" or 1730mm of inner out, minus the square drive that should be at the end, so definitely the cable and it must have broken pretty near the gearbox. As the gearbox has been out and back in December and January, it's possible those disturbances have caused the problem. The Parts Catalogue quotes GSD 116 for the V8 at 56" or 1422mm, i.e. way shorter than what I have pulled out! What I have is probably a 72" cable for LHD, for some reason. Googling GSD116 does not come up with any hits, even though it is listed for several years and markets in the Parts Catalogue.

Browsing various suppliers shows GSD117 at 60"/1542mm seems to be the one, and Leacy (despite showing it as out of stock) say they do have it and several pounds cheaper than anyone else. However their web site says that cable is for Mk1 OD cars, which agrees with the Parts Catalogue, which says that cable was for various other years and markets as well. Leacy say that GSD115 (which isn't shown in the Parts Catalogue) is the right one for the V8, but some sources show that as 57". I don't want to go any shorter than I have to as that may mean the speedo has to be back in the dash to reattach the cable from behind, or fit that end first then the gearbox end. However Leacy assure me that is 60", as do a couple of other supplier web sites, so I go for that.

I've seen a complaint that the end of replacement cables is too big to fit through the hole in the bulkhead and they had chosen to cut the fitting down a bit in preference to increasing the size of the hole slightly. The gearbox end is larger than the speedo end so the cable has to be pushed up from below into the cabin, not down from inside the cabin. I wondered if that was the problem, but he never replied. On a trial removal of my cable even with the grommet removed (of course) the speedo end looks like it will only just fit through the hole - and has to be dead square to it, so with the replacement cable I'll see if the speedo end will fit down the hole first, as that will be easier from inside the cabin that struggling from underneath, especially if I have to enlarge the hole.

The cable arrived, it was 60", but the speedo fitting was way too big for the speedo! Good job I did a test-fit on the bench before installing it, which was probably only because it was raining and I didn't want to get the cars out to start work. So as well as different suppliers giving different part numbers and lengths for the same model years, it looks like there are two sizes of speedo fitting as well. The poly bag this came in had no labels, so could be for a completely different car. I wondered if it is the difference between 4" and 80mm instruments, but I've found a supplier that gives the internal sizes of the speedo and gearbox ferrules. They give different listings for 62-63 OD, 67-76 OD, LHD Auto and V8 but they all have the same manufacturers part number - GSD115. There is another listing for 62-63 non-OD (GSD103) but all of them have the same ferrule sizes, which tends to rule out a difference between 4" and 80" - prior to 77 at least. For 77-on the Parts Catalogue quotes GSD315, but I can't find that listed on the same site, and no matter what vehicle I look at the same ferrule sizes are given for all of them! The vendor isn't accepting messages, so that's a dead-end. Enquire with Leacy and next day they come back and say that checking their stock things were in the wrong bins, and based on what I had been able to tell them about dimensions they were able to sort that out, and are sending me another cable.

While waiting for that I get the old cable out - I thought I was going to have problems as there is no access from above in the engine compartment, and pulling and pushing from the footwell and from underneath didn't move it very much. The cable was wrapped round the carb overflow tube, but with that lifted out of the way the cable sprung down to hang straight down from the hole in the bulkhead which was now clearly visible from underneath, so was relatively easy to get out except that the ferrule has to be square to the hole. The gearbox end was also a bit of a fiddle, despite only recently being fitted, as access is very restricted over the fixed crossmember. But the same pair of grips I used to finally tighten it got it started, and I moved it most of the rest of the way with fingers. A couple of times it jammed and I resorted to the grips again, but that turned the cable with it, and releasing the grips the ferrule just sprung back. I had to turn the ferrule with the grips, then wiggle the cable about until just that sprung back, and repeat, until I could go back to fingers. It's cable-tied to the services either side of the removable crossmember, and passing above that instead of below, making the exit from the gearbox slightly tighter than would be under the crossmember and clipped to it as it should be, so I looked out the parts necessary to fit it as originally instead. The old cable has a 92 date code, so not that long before my taking over Vee. With the cable removed and a clear view of the kink by the gearbox shows daylight between the turns of the steel spiral, so that is what caused the inner to break. The remains fall out of the gearbox fitting:

The replacement cable arrives, and one thing I had noticed with the first replacement was that the gearbox end was flattened instead of the square-section I was expecting, and is how all three speedo ends and both broken and 2nd replacement cables are. Left and centre pictures are of the flattened end of the first replacement, the right picture of the 2nd replacement. However I did try the flattened end in the speedo on the bench as a test, the speedo did operate, so probably would have been OK in a gearbox drive:

The 'nuts' can vary from cable to cable - finely or coarsely fluted, or knurled, at either or both ends. Someone on the MGOC forum posted that on his new GSD117 cable the inner was too long and when fitted to the gearbox the ferrule in the inner at the speedo end protruded and the nut wouldn't reach the speedo, so he chose to cut the excess off the gearbox end, which left it frayed, hardly ideal. His photo also showed the flange at the speedo end as turned over rather than cast, and only just at that looking like it wouldn't take much for it to come out of the nut, unlike the very definite cast stepped flanges on three I have:

I measured the speedo ferrules of the original and second replacement cables, to find the new one smaller than the original, which was something of a surprise - original on the left, new one on the right. Maybe the 'original', with its 92 date code, was over-size and the hole had been filed out for that to fit. Nevertheless I trial-fitted it from above first and it went in easily:

After someone had said it was impossible to get the ferrule up the bulkhead hole while fitting the cable, and he had to push it up with a stick afterwards, I wrapped some tape round the cable to hold the ferrule near the top, and it went through straight away:

I probably should have done the same thing at the gearbox end to stop the ferrule sliding down more than anything else, but it went on easier than the old one came off, or went on when I refitted the gearbox. The trick is to not let the cable take up a natural angle, which will not position it in the right place or at the right angle, but to hold it square and central to the end of the gearbox drive, which allows you to get the ferrule started. Care is needed here not to cross-thread and jam it. Push the cable up to the gearbox drive all the time, and you should be able to tighten the ferrule all the way - subject to the size of your hands!

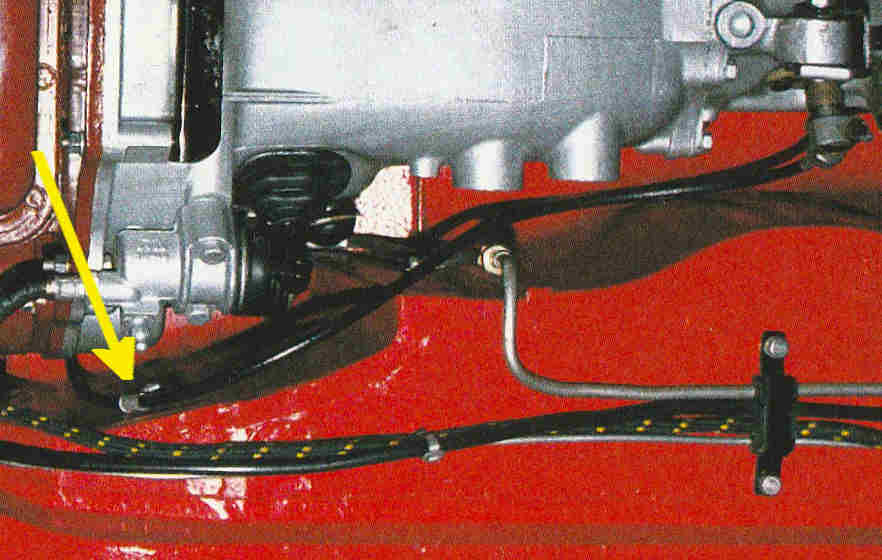

Next job was to clip it to the underside of the removable cross-member, with parts I had to hand. That allowed the forward end of the cable to hang down below the chassis rail:

So I used a cable-tie to hold it up out of the way. The cable now makes a smoother exit from the gearbox then previously. Note this shows the gearbox earth strap in the 'correct' position as shown in the manuals - right-hand side front:

I wasn't aware there was a pukka fitting for this originally so hadn't ordered one with the cable, but it is clip PCR809 with split ferrule ACH8529. Even that isn't straightforward as the Parts Catalogue specifies PCR809 for RHD where overdrive is not fitted, and AHH7178 for RHD with overdrive, but not V8. I've not found a picture of this to compare. Later on it says LHD from May 72 and all V8s use PCR809. Clausager says North America got modified speedos and cables from that date, implying V8s had the same and later cable, but the Parts Catalogue shows the V8 cable GSD116 being used for RHD OD cars from the beginning of production. All very confusing.

I've only seen one supplier selling these as single part, but the usual suspects have the two components:

Looks like the same support is used on the side of the tunnel as the cable comes up to enter the cabin:

I'll add the makings to my next order to combine the postage rather than getting them now, along with replacement bulkhead grommets RFN305 as the one I took out is hard and misshapen. The above supplier shows cables with the grommet already fitted, which would be preferable, but at more than double the price I paid. The one I took out had been cut to retro-fit, I have no problems doing the same. A new one may stretch over the speedo ferrule (unlikely, having obtained one I didn't even try), but I'm not taking the speedo out again just for that!

|

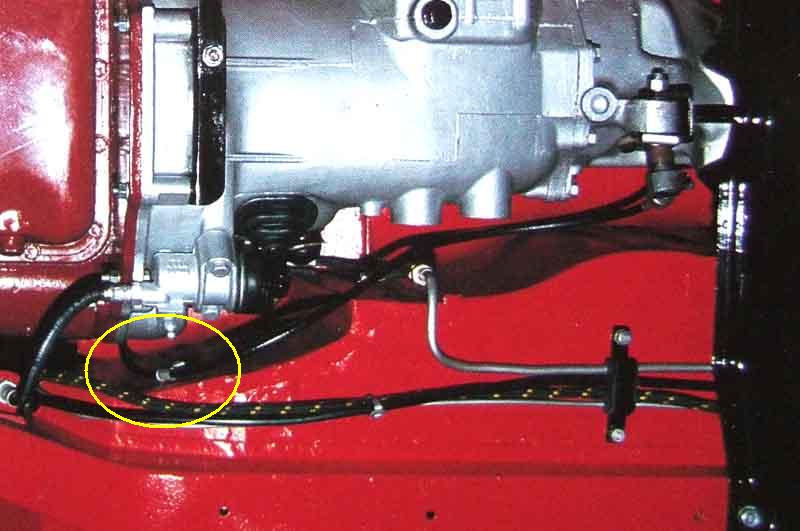

On my 73 roadster the cable (arrowed) comes off the output of the OD conveniently (not!) above the fixed crossmember then turns forwards and under the floor to meet the pipes and cables running the length of the floor, and over the removable cross-member. The notch in the fixed crossmember shows that the cable is designed to exit at right-angles to the gearbox, and then turn forwards. The 1964 3-synch non-OD car pictured in Clausager (p76) does not have this notch.

It also appears to show that my removable crossmember is the wrong way round! The downward dip for the earlier restraint rod is supposed to face forwards, and the hole for the restraint rod should face rearwards. Neither is the lower bracket for the restraint pin bolted to the crossmember, so that may be the wrong way round so the holes don't line up. |

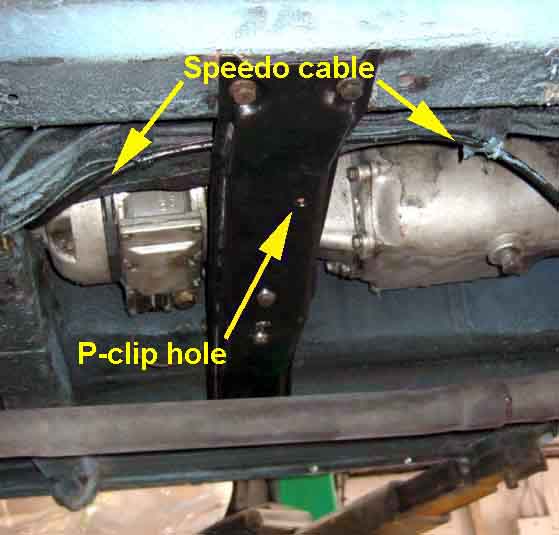

The speedo cable should pass below the crossmember and be supported with a P-clip and split ferrule in a tapped hole:

But as Bee's crossmember is the wrong way round it passes with the pipes and cables above it ...

... and goes forwards in a bit of a tangle with everything else:

Vee's crossmember being the right way round has the tapped hole for the P-clip that would support the cable under the crossmember tucked up into the recess, but was also routed above. In the correct position the cable takes a slightly shorter, straighter route, albeit more exposed. But as both cables have always been cable-tied above the crossmember with the other cables and pipes in my ownership and haven't exhibited any problems with routing, I've left them there for the better protection.

That is, until Vee's cable broke not long after, so I routed the new one correctly.

Clausager shows this Mk1 with another P-clip on the side of the tunnel:

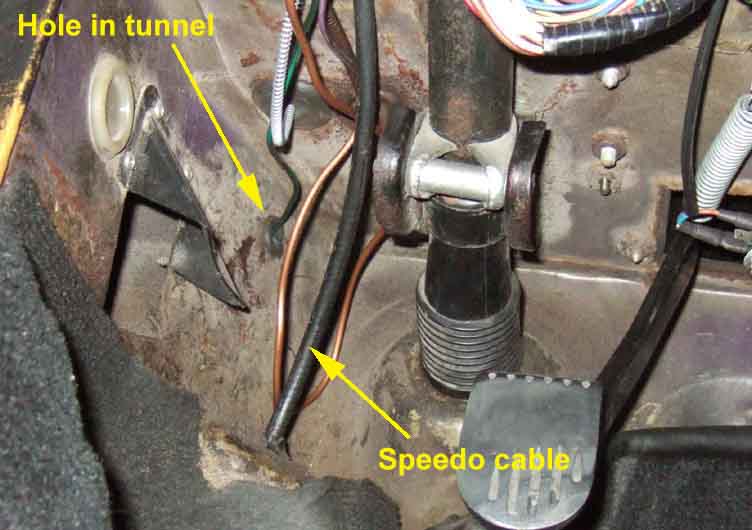

Speedo cable entry in the footwell of a 1973 RHD with the cable coming from the top of the 'foot rest', and an originally unused hole in the side of the tunnel at the top which I'm using for an extra wire.

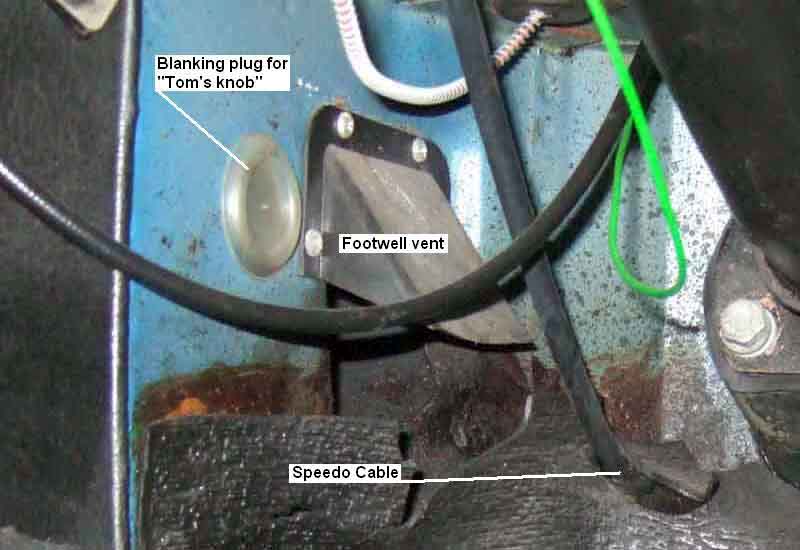

A 1975 V8 with the cable entering in the same position, but no hole in the side of the tunnel.

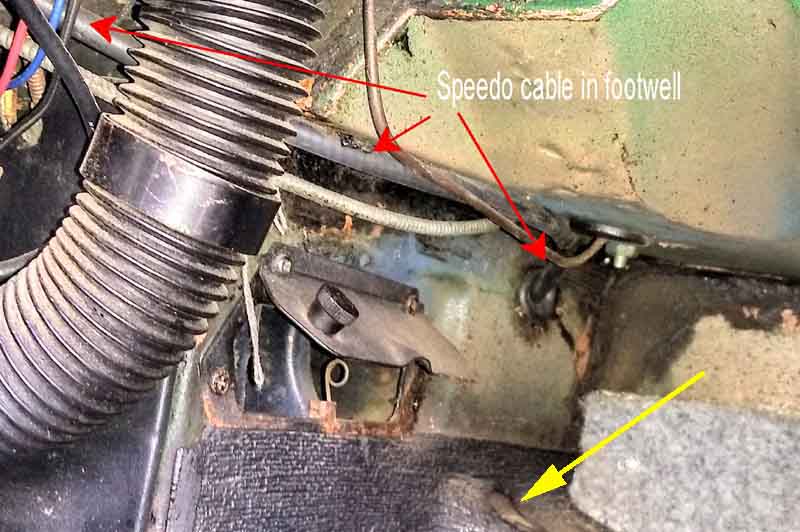

On a 1970 LHD the cable enters the cabin via the hole on the side of the tunnel ... (Bill Etter)

... proceeds behind the dash ... (Bill Etter)

... to end at a right-angle drive unit on the back of the speedo: (Bill Etter)

This 1968 has a hole in the rubber mat at the top of the RHD clutch foot rest but it's not clear if there is a hole on the panel (bunged) on not. But I have seen a picture of the cable coming in at the top of the footrest on an LHD, and going back out again through the side hole in the tunnel. My initial thought was that this was very odd, but if it didn't do that it would need some other support in that area in the engine compartment while it continued across to a hole in the bulkhead in front of an LHD driver.

1974 LHD car from Clausager, showing (probably) how the speedo cable and heat control cable pass through the bulkhead in front of the driver. With this arrangement a right-angle drive is not needed as the cable goes straight onto the back of the speedo, and Clausager says these were deleted from May 1972. I've seen a variation on this where the cable enters the cabin in the RHD position, but then goes out again through the hole in the side of the tunnel under the heater, which is used for the entry in the picture above:

1976 with EGR service counter (arrowed). Note the bracket attaching the cable to the top of the heater casing, my 75 V8 has that stud and I always wondered what it was for: (Bill Etter)

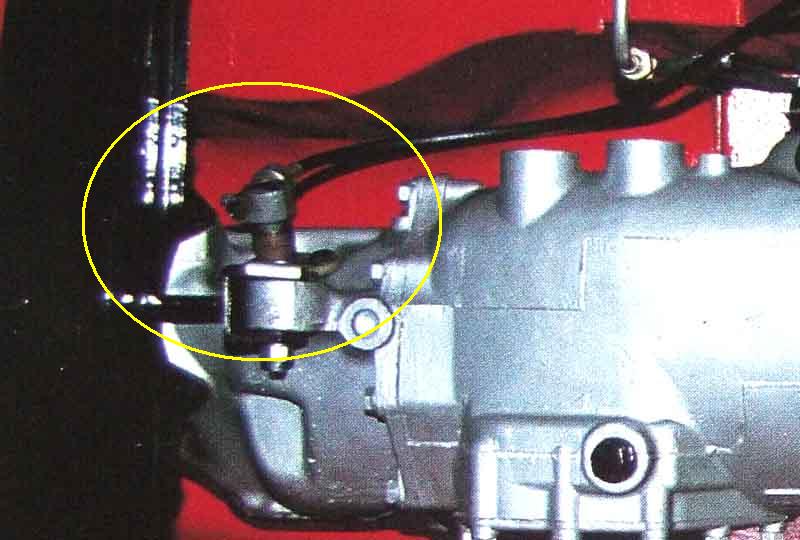

Gearbox end: (eBay)

This 1963 non-OD car has the cable connected in front of the removable cross-member with a right-angle drive. This part of the non-OD gearbox is much narrower than the OD, and as the spigot points backwards slightly the cable without a right-angle drive would have to turn through more than 90 degrees to go forwards: (Clausager)

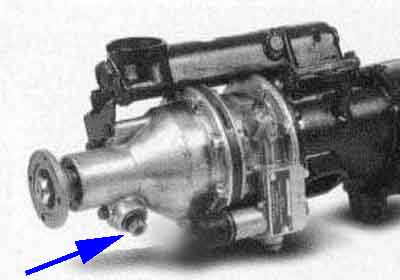

Three-synch OD: The speedo take-off is spaced back from the bulge of the OD a little, at a right-angle, and the bulge is less and tapered. This creates room for a right-angle drive, without which the cable would have to turn through 90 degrees: (Chicagoland MG Club)

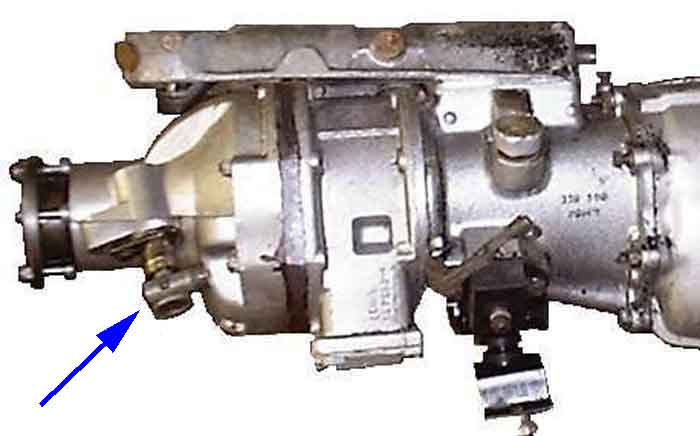

Four-synch non-OD: Close to the wider part of the main gearbox casing and bellhousing, also angled forwards, which means a right-angle drive can only be fitted if the cable leaves it virtually straight up or straight down. Without the right-angle drive the cable will already be pointing forwards by a significant amount, the remainder of the curve forwards can be accomplished under the floor ahead of the removable crossmember to meet the other pipes and cables: (Chicagoland MG Club)

Rubber-bumper four-synch OD: Someone has fitted a right-angle drive to this, but because the take-off is angled forwards, and is very close to the wider part of the OD, the cable can only be attached to it if the right-angle drive points upwards (or downwards to the wrong side) which is counter-productive ...: (Chicagoland MG Club)

... and there is a notch in the fixed cross-member to allow the cable to come down and forwards without (note this was before I replaced the clip on the removable cross-member with the pukka item):

Automatic: Exits at right-angles so would benefit from the right-angle drive as per the 3-synch boxes:

The copper washer 3H550 is shown in this image from Brown & Gammons. It also shows a 'silver' washer but doesn't discuss it, although mentioned elsewhere are one or two O-ring oil seals that also fit into the angle-drive:

The EGR valve service indicator counter: (Bill Etter)

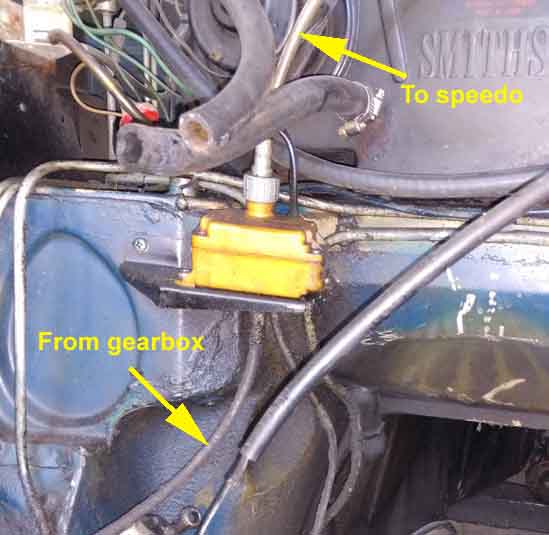

Mounted on a bracket screwed to the lower firewall. The engine has been removed for a clutch change which is why the gearbox cable appears to go forwards, and not down and back to the gearbox: (Bill Etter)

From the EGR counter the cable goes across the bulkhead and through in front of the speedo, so a right-angle drive is not required: (Bill Etter)