16-tooth 17H8021 for 3-synch OD, note the scroll on the shaft:

26-tooth 22B654 for CB 4-synch non-OD, with scroll:

21-tooth 37H3463 for CB 4-synch OD and all V8s, it's said that repros don't have the original scroll: (Moss Europe)

5-start 7H8294 for 3-synch OD (B&G incorrectly show a blue plastic item):spacer

10-start 22B468 for 4-synch non-OD, there is also a white plastic version 22B649:

8-start 22B3464 for CB 4-synch OD and all V8s:

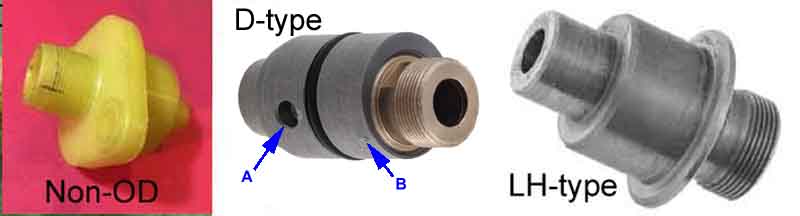

Non-OD uses a gasket 22H903 to the gearbox casing and seal 13H4024 for the pinion spindle.

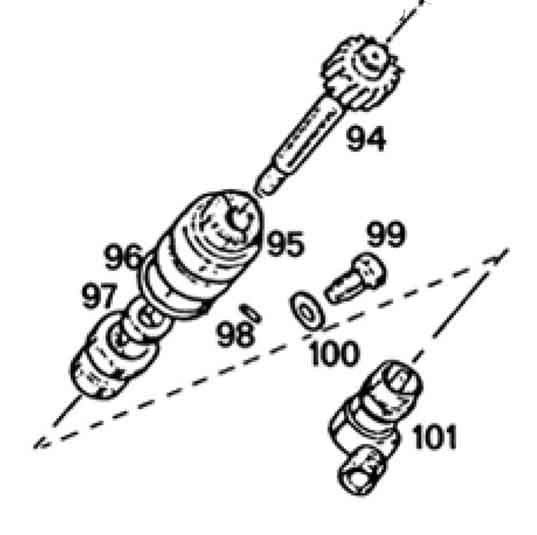

D-type OD housing (95 below) 17H8012 uses O-ring 7H8304 (96) to the OD casing and seal 060247 (97) for the pinion spindle. There is a pin 17H8034 (98, possibly 'B' above) through the housing which looks like it retains the 'brass' threaded section, which unscrews to enable replacement of the seal. How one removes that pin I don't know, there are flats on the brass section which implies it unscrews, so maybe one shears the pin the clears the two holes afterwards: (Moss Europe)

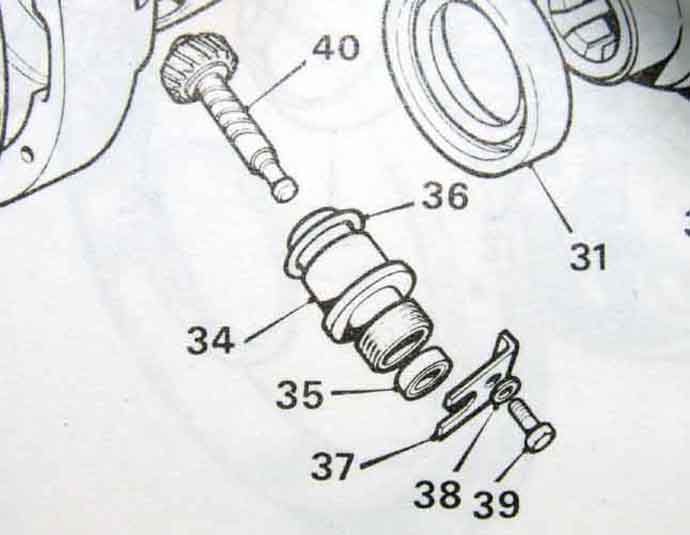

LH-type uses O-ring (36) 37H3879 to seal the housing to the gearbox casing and 'seal-oil' (35) 37H1956 for the pinion spindle. The seal is removed either with a very small puller from the cable end, or by drifting it out from the pinion end. Replaced by pressing it in with a suitable sized socket that fits inside the housing, to push the seal all the way down. 37, 38 and 39 are the clamping fork, screw and washer: (Leyland Parts Catalogue)

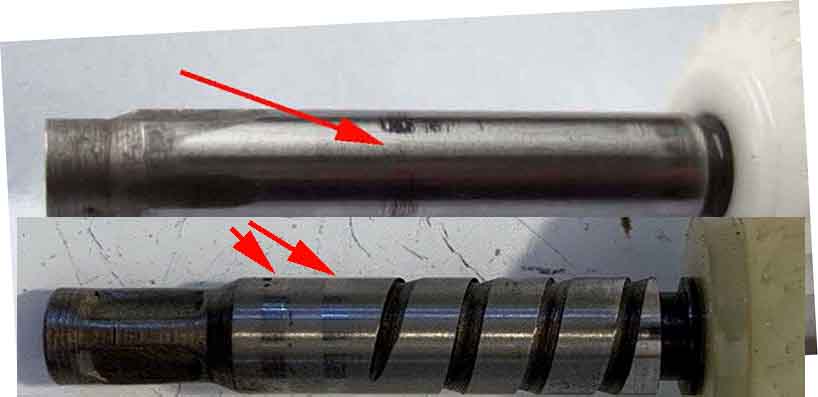

The spiral shown on the shaft of the pinion is a scroll-type seal which is designed to push oil that gets onto the shaft back into the gearbox, although only when the car is moving forwards of course. Currently available pinions do not have the scroll. But it begs the question as to why there is a scroll and a seal, surely if the seal is over the spiral part oil will leak past the seal? But comparing the plain one that came out (top) with a 2nd-hand one with a scroll (bottom) whereas the witness mark for the seal (arrowed) on the top one is well into the scroll of the lower one, the lower one seems to have witness marks from its seal closer to the end in the plain part. As the end of the pinion is narrower than the main part of the shaft (and scalloped on the plain one), the seal would have to be pushed far enough into the housing to be past that, but not so far as to reach the scroll. Unless ... the seal doesn't go in far enough to reach the scroll where there is one, and the arrowed marks on the upper one are from something else altogether. I didn't think to measure the depth of the recess and compare with the pinion:

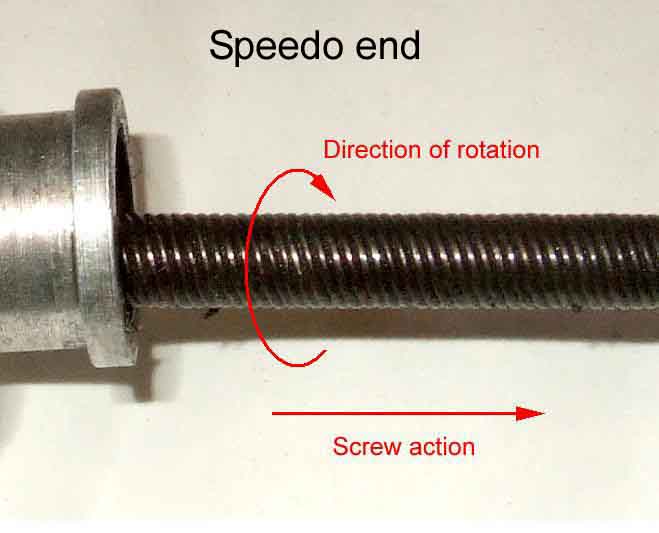

The speedo cable has its own scroll action (see Archimedes Screw) but in this case the construction of the inner which is designed to tighten the cable in on itself as the car moves forwards tends to move any oil at the gearbox end of the cable up to the speedo. If the inner were wound the other way it would tend to unwind in the outer and jam:

With Vee's replacement cable seemingly pumping oil into the speedo I decide to get both seals, replacing just the oil seal in-situ to begin if I can, removing the housing from the gearbox if not and replacing that O-ring as a matter of course (note that oil will almost certainly come out with the pinion housing removed). However Googling those numbers doesn't come up with any of the usual suspects, but browsing B&G comes up with NKC105A and NKC101A respectively, also available from others. But I want the cross-member clips and bulkhead grommet as well from having replaced the cable, and none of B&G, Moss, MGOC or Leacy have all five items! Rimmer's does though.

With the cable removed ... there doesn't seem to be a seal! Or if there is, it is pushed well down into the housing leaving more than enough space for a second seal:

It's a conventional lip seal which has to be drifted into the housing, so unless the OD rebuilder used something else which fell out when changing the cable, and I didn't find it, means they didn't fit one! Trying to press the new seal in wasn't working (some housings seem to have a tapered entry which would make starting the seal easier but this one doesn't), so with it wedged in at a bit of an angle I refitted the cable and started tightening the cable nut until the flange on the cable reached the seal and started pushing it in. Then removed the cable and worked round it tapping it into position bit by bit, before finally refitting the cable. As the nut starts bearing on the cable flange and that starts bearing on the seal the outer starts turning with the nut. There is what looks like a hex on the outer but none of my spanners fit it, so I have to grip that with Mole grips from below while using channel grips to turn the nut from above to finally tighten it.

So inner removed from the speedo end and cleaned yet again, replaced without fully fitting the speedo in the dash until I've done some miles to see if any more oil appears on the cable. If it does, and it starts working its way up the cable, I'll have to remove the housing and have another go, and since reinstalling it stuff I've read tends to indicate that the seal should be further in. The photo's not too clear but peering down it certainly didn't look like the end of a lip-type seal that I could see. But browsing other pictures of the pinion I find one that has a section of shaft at the lower end with flutes as well as the reduced diameter section, so the lip of the seal will have to be above the flutes to work. Meaning the one I've added won't do anything, and there probably is one already in there! Oh well, looks like I'll have to get the housing off, with some of the oil draining out to remove the shaft and drift the seal(s) out. In which case probably better to fit another new one.

Housing removed and dismantled, with the modified screwdriver I used to drift the seal out from the pinion end:

That seal goes a long way down inside the housing:

Fine scratch running the full length of the pinion shaft, and no scroll:

But more importantly a gap in the witness mark from the oil seal which indicates there has been a gap between seal and shaft there.