Gearbox crossmember Detail

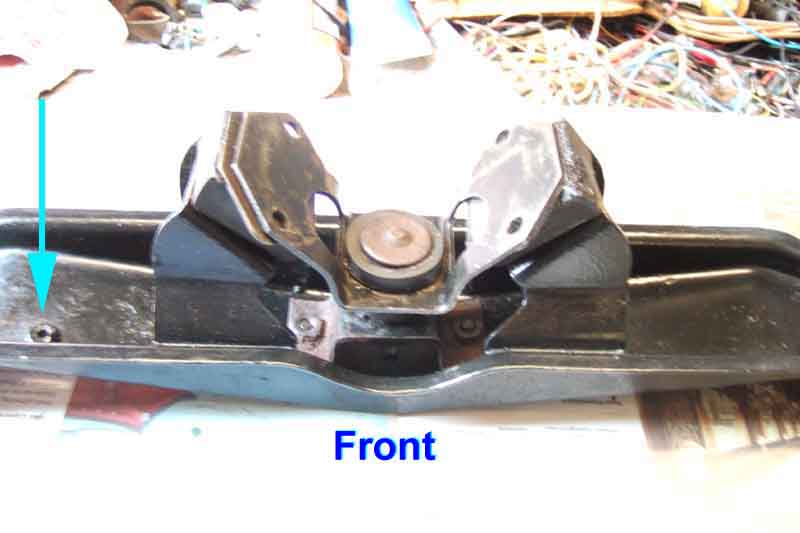

The front face has a dip, and the rear face is straight with various holes, both of which accommodate one of the two restraint rods that were used at various times. The welded nut arrowed is for the speedo cable clip when OD is fitted, and is on the right-hand side when facing forwards:

Note that the gearbox earth strap (rubber bumper cars) is fitted to the left-hand side here, the manuals show it fitted to the right-hand side i.e. the same side as the speedo cable clamp welded nut:

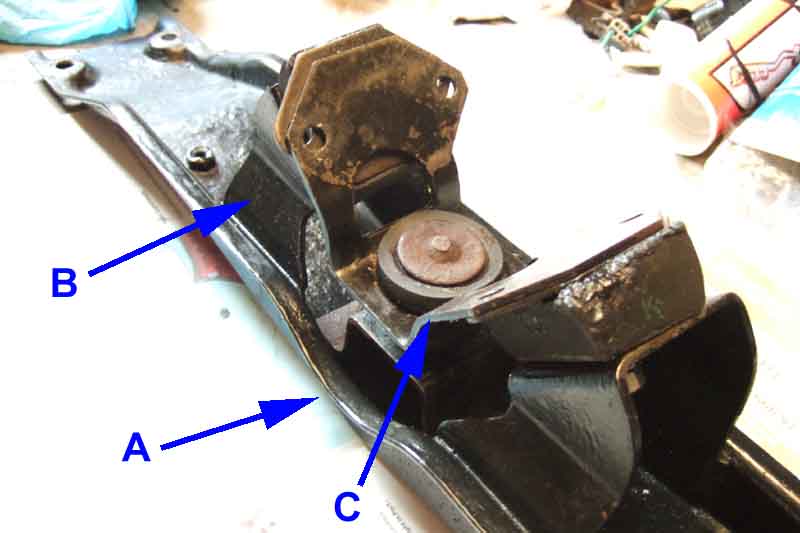

On the side with the dip 'A' the face of the welded brackets 'B' is angled back, and the front edge of the upper yoke 'C' is flat:

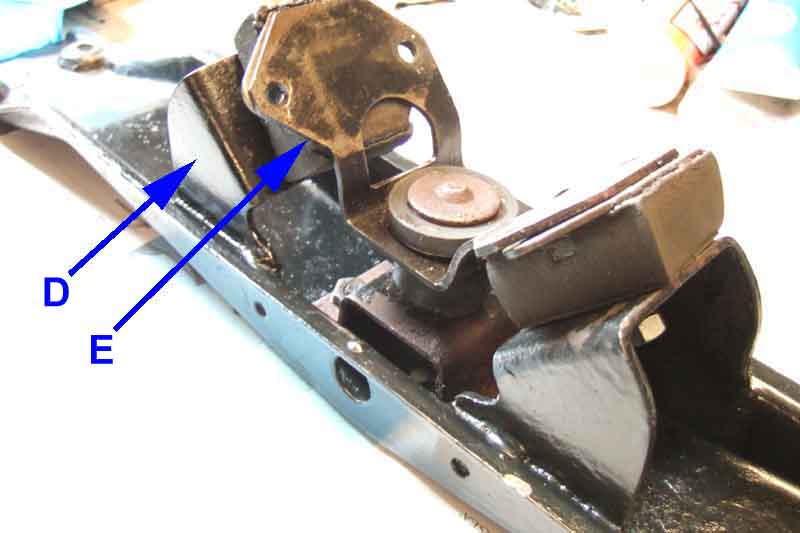

Conversely the rear face of the welded brackets 'D' is vertical and the rear edge of the upper yoke 'E' is stepped, which with OD apparently gives more space to access the bolts that go into the gearbox:

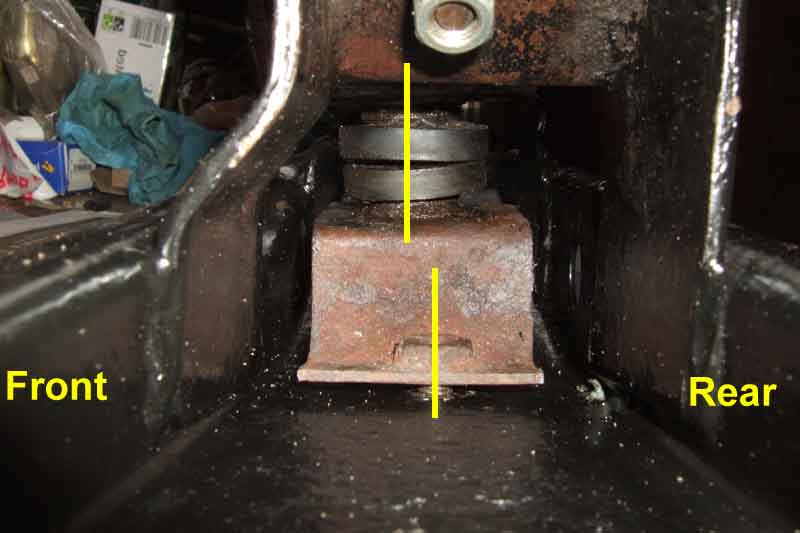

The lower restraint-pin yoke is orientated such that the welded nuts are behind the centre-line of the pin, i.e. vertically below the mount studs:

The mount stud goes though the front-most of the two holes in the bracket:

The upshot is that the rubbers are positioned centrally across the crossmember, and the lower yoke welded nuts line up with the holes in the crossmember:

Perished mount rubbers:

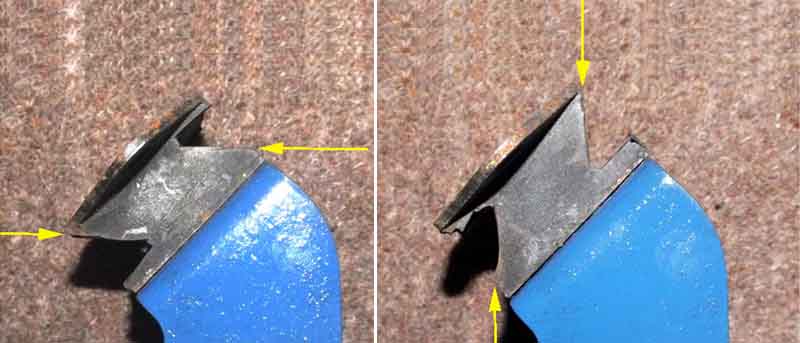

If there weren't already enough options for assembly some suppliers now have the rectangular rubber mounts with cut-outs, meaning that whereas before they could be fitted either way round, now there is a difference in the shape of the rubber and the forces acting upon it, making them 'handed'. In the orientation as shown on the left the unsupported faces are horizontal, but as fitted on the right they are vertical. Logic dictates that vertical is correct, as the main weight of the gearbox acts vertically so the rubber will be in compression. If fitted horizontally the rubber would experience a significant shear load. It's true that when in use the forces could be in any direction, including fore and aft, but as with very few exceptions cars spend more time sitting than running, it seems that fitted as shown on the right is preferable: (Graham Barker)

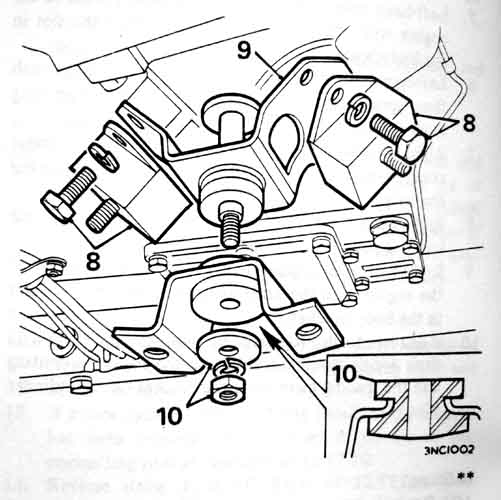

Showing the assembly of all the central restraint pin (once the crossmember has been removed!). The flat edge of the upper yoke faces forwards (9). Inset '10' shows the insertion of a bush into a yoke, in this case the lower yoke with the wider diameter inside the yoke. Invert the image for the upper yoke: (Leyland V8 supplement)

Showing the earthing strap (8) on rubber bumper cars and V8s, one end under the head of a bolt securing the mount to the gearbox casing, the other under the nut on the mount stud. Shown on the left-hand side front here (as I found it), the manuals show it fitted to the right-hand side front:

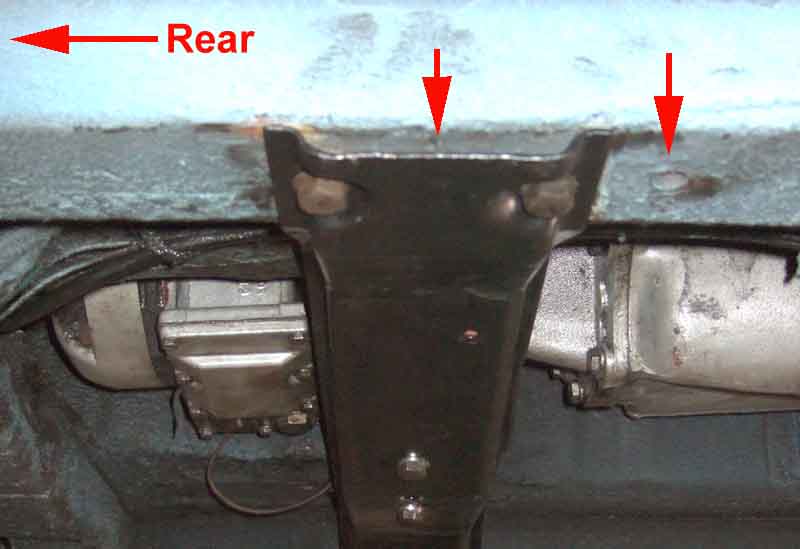

4-sync crossmembers use the rear-most mounting position, unused holes indicated. 3-sync non-OD use the same holes, the extra set were there before the auto option was available so not for that, maybe for the 3-synch OD box:

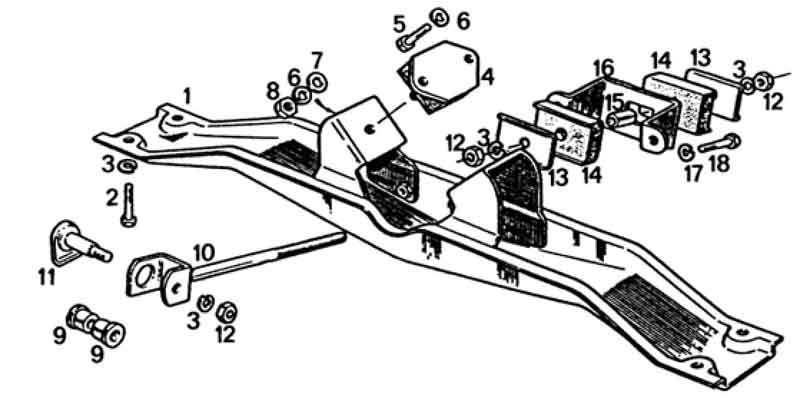

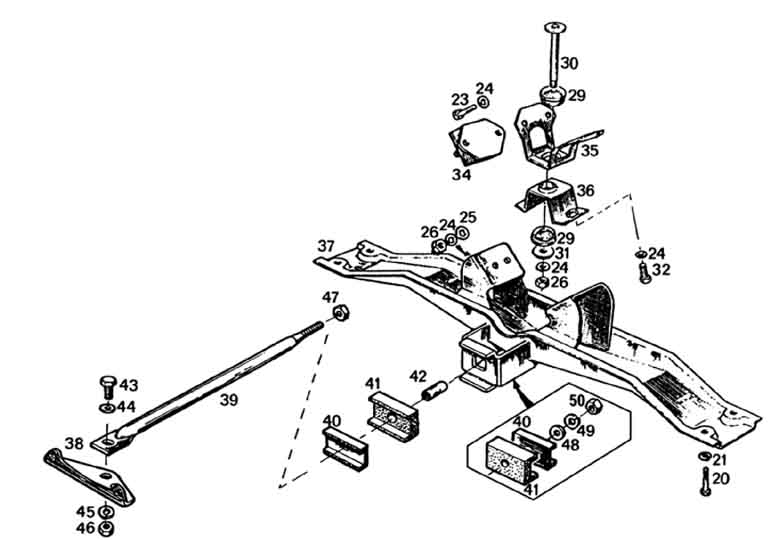

Restraint Rods: Mk 1/3-synch cars had a crossmember with just a single hole for each gearbox mount stud. Roadsters had welded nuts on the rear face for a restraint rod bracket. A short rod passed through the crossmember and bracket and was retained by a nut. The front of the rod has a 'U'-bracket that goes around a protrusion on the bottom of the gearbox casting close to the crossmember, and a special pin goes through the bracket and protrusion with rubber bushes between them. They don't appear to have the yokes, bushes and pin at this stage: (MG Centre Wrexham)

(Moss Europe)

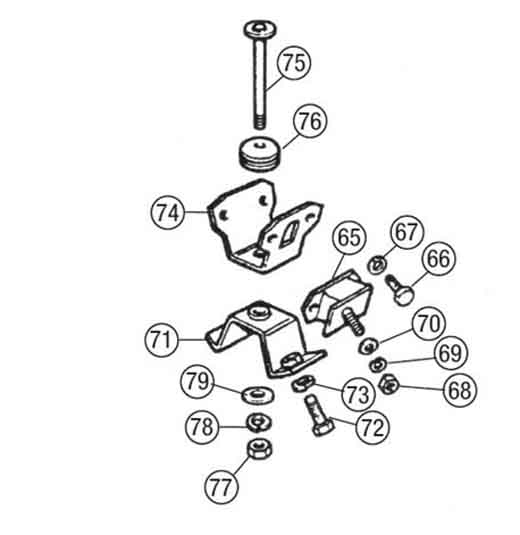

Mk 1 GTs don't appear to have the restraint rod, but have yokes, bushes and pin instead. This upper yoke (item 74) in the Parts Catalogue and Rimmers is shown as symmetrical so either way round makes no difference, the lower (71) is probably the same. Although these are not as 'positive' at restraining forward movement as the roadster rod they will limit it. They also prevent any untoward lifting of the gearbox tail should the rubber mounts part which could tip the fan into the radiator, and almost certainly would prevent them parting in the first place: (Rimmers)

Mk1 GTs also have control brackets as part of each engine mount that restricts how far the engine can move forward. Perhaps not quite so positive as a restraint rod, but just as effective as keeping the fan away from the radiator. Unfortunately if these front control brackets are left out during an engine removal and refitting the engine has no positive restraint, just the floppy (in the fore and aft direction) yokes, bushes and pin. Very few seem to exist in the wild going by past comments (although Michael's has them), but they are available from the usual suspects, part AHH7890 variously described as 'Bracket control', 'Bracket - Engine Surge', 'Recoil bracket', and 'Restraint Bracket'. The mounts that bolt to the gearbox are different to those on the roadster.

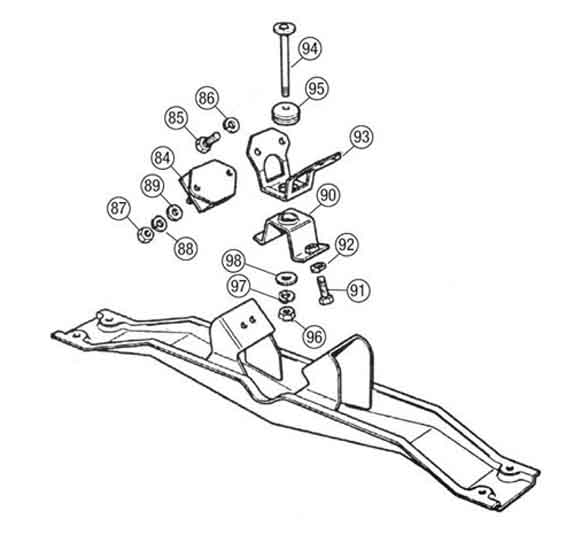

All Mk 2/4-synch cars have a crossmember with two holes for each gearbox mount stud so two more options for assembly, and no welded nuts for a restraint bracket (and hence no restraint rod), although the holes are still present. The upper (93) and lower (90) yokes with bushes and pin are different to the Mk1 GT, both asymmetric which makes a difference according to which way round they are fitted. All GT and roadster parts are now common. The quantity of the front control brackets was reduced from 2 to 1 (penny-pinchers again), for markets other than North America, for the 1972 model year. These cars would definitely benefit from retro-fitting the front control brackets if they are missing.

In Feb 74 (still chrome bumper) a new restraint rod was added to North American cars. This used a welded bracket on the front face of the crossmember, and a longer rod going all the way to a bracket that attaches to the two bottom bolts that secure the bell-housing to the engine. Other markets got this arrangement at the start of rubber bumpers, but despite this very positive restraint being used again, and the yokes, pin and bushes, the front mount control brackets were also apparently still provided (making no less than three restraint systems!), 2 for North America, 1 elsewhere as before, until the engine mounts changed from rectangular to round at the start of rubber bumper production in September 1974, which prevented the use of the front control brackets. The crossmember brackets again have two holes for the stud on the rubber mounts.

(Moss Europe)

Bracket 38 BHH1542 used here for the mount on the restraint rod existed in a simpler form on earlier cars (GEX 7189 for 3-synch, GEX7190 for 4-synch) purely as a mounting point for the strap supporting the front of the exhaust system. All used thick washers as spacers on the two lower bell-housing bolts - between the bracket and the bell-housing NOT under the bolt head, to space the bracket back from the split-pin in the bell-housing drain hole. I've not been able to find these spacers listed with exhaust, engine or gearbox components.

The V8 only ever had the Mk2 yokes, bushes and pin as part of the crossmember assembly, never a restraint rod or front mount control bracket.