Contents

Index

So you think you want an MGB or V8?

Body

Brakes

Clutch

Cooling

Electrics

Engine

Fuel

Gearbox

Heater

Ignition

Propshaft

Rear axle

Steering and Suspension

Wheels and Tyres

Miscellaneous

Downloadable PDFs

The sectioned MGB at the British Motor Museum, Gaydon

Braking System

|

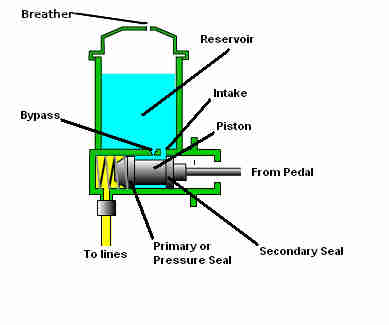

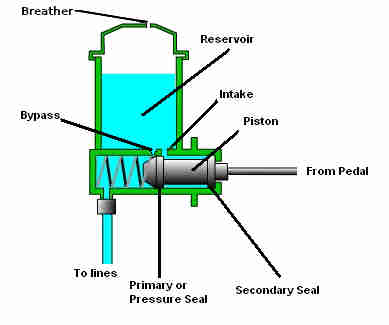

December 2017: Someone has just asked 'how do brakes work' in terms of what releases the brakes after they have been applied. They also asked if it was the pedal being released that pulled the fluid back and so pulled the brakes off, but that definitely isn't the case. The design of both master cylinders is such that when the pedal is released and pulls the push-rod back, a spring inside the master cylinder pushes the piston and its seals back. Normally all the fluid that flows out of the master cylinder when the brakes are applied flows back in when they are released to release the pressure in the calipers and wheel cylinders. But if for any reason it doesn't, for example when pedal bleeding (can be done but not ideal) and some fluid has been expelled from a bleed nipple, then as the piston comes back more fluid flows from behind the pressure seal and the reservoir so the system remains full of fluid and at zero pressure, positive or negative. See the description of the master cylinder for how this happens. But even when all the fluid does come back, on single-circuit masters at least it does so through a restrictor, which only gradually releases the pressure in the pipes etc. As the master piston comes fully back straight away some fluid is always pulled from the master into the cylinder, to be pushed back into the reservoir again as all the fluid comes back through the restrictor.

Source: Motor Vehicle Maintenance & Repair Stack Exchange

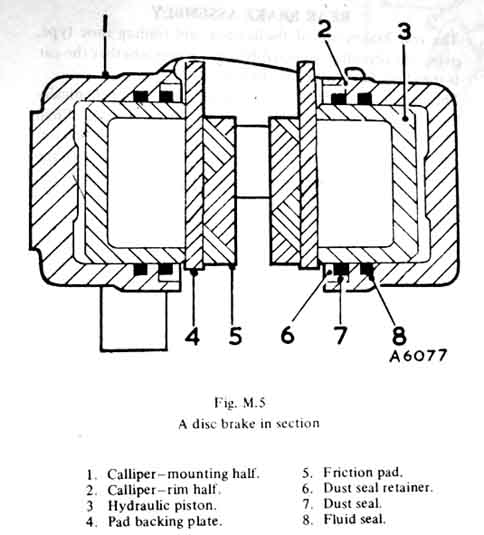

So how are the brakes released? Rear brakes with drums and shoes have return springs to pull the shoes away from the drum, and pushes the wheel cylinder pistons back into the cylinders, which pushes fluid back towards the master cylinder. But caliper pistons don't have return springs. They are self adjusting, and in normal use the pads sit just fractionally off the discs, maybe rubbing very slightly. As the brakes are applied fluid pushes the pistons out, past the seals, which pulls on the seals very slightly. When fluid pressure is released the seals will tend to return to their former shape and position, pulling the pistons back into the caliper very slightly, taking the pressure of the pads off the discs. There is a secondary effect on cars like the MGB in that there is a small amount of end-float at the front hubs. This end-float allows the hub and disc to rock from side to side very slightly when driving, which also tends to push the pads and hence the pistons back a little. Some pooh-pooh this secondary effect saying not all cars have this end-float. That's true, and the intention of end-float isn't to push the pads and pistons back, but nevertheless it does happen. If you Google 'pad knock back' you can find many descriptions of the same effect caused by worn wheel bearings.

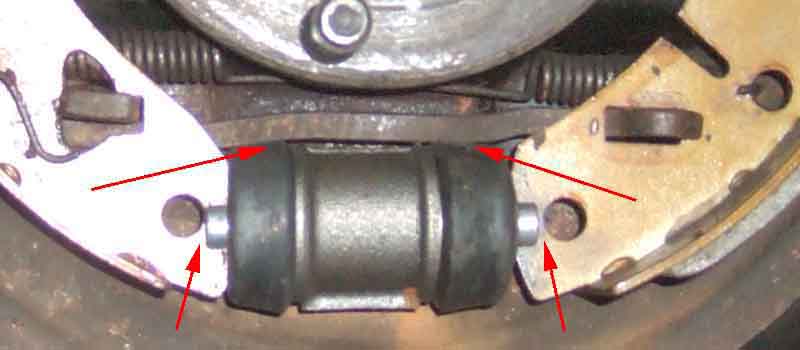

| |

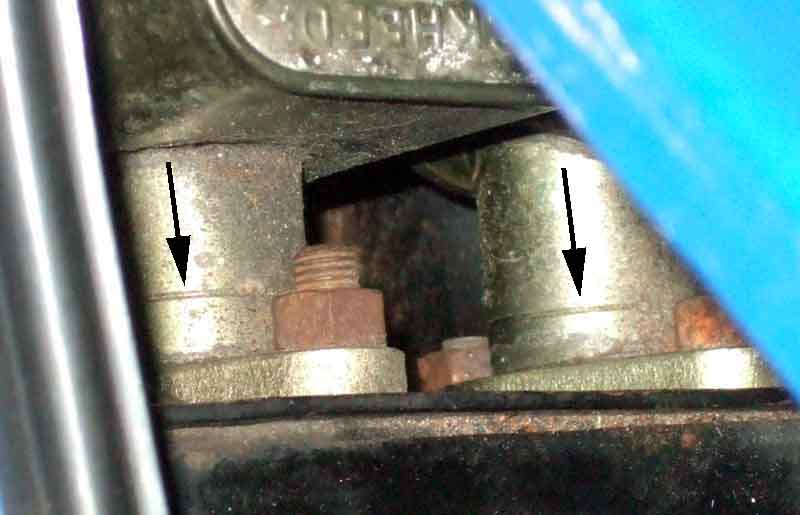

Another technique for persistent sponginess

Caliper bleed nipples are 3H2428 said to be 3/8" 24 UNF thread and 11mm (or 7/16") spanner/socket size, and wheel cylinders are 513118A said to be 1/4" 28 UNF thread and 7mm socket/spanner size.

For the original system with the single hydraulic circuit brakes should be bled starting with the longest run i.e. left-hand rear, then the next longest i.e. right-hand rear, and so-on to the shortest. Originally this was the right-hand front on RHD cars and left-hand front on LHD, but on rubber bumper RHD cars with the remote servo it is the left-hand front that is the shortest as there is a pipe direct off the servo to this brake. LHD cars also have the left-hand front as the shortest run on all versions. It may well be beneficial to release the handbrake while bleeding the rears, see below.

For dual-circuit systems later Workshop Manuals and Haynes say to bleed the caliper nearest the master cylinder first, then the other caliper, then the rears - order not specified. These, including the brake-failure shuttle switch, are outside my experience but I can't see how they can be pedal-bled very easily as the circuit not being bled will still pressurise and stop the pedal moving to the floor, which will reduce pedal travel, and hence the amount of fluid that can be pushed through the system that is being bled with each operation of the pedal. That may be the reason why the calipers are bled first, as any air in the rear circuit will allow the pedal to travel further when bleeding the fronts (and the front brakes are more important than the rears), and again releasing the handbrake or even disconnecting the handbrake cable from one of the back-plates may help. Continuous-flow bleeding as with a Gunson's EeziBleed should avoid both these issues, as well as making the job much easier on all systems. However on both my (single-circuit) cars I find that whilst the EeziBleed is perfectly adequate for the rear brakes, if the fronts have been dismantled and air has got into the system additional steps are needed, as after using the Gunsons alone I s till get a 'long' pedal. This can be 'pumped up' but after only a few seconds that effect is lost and the next application results in a long pedal again (the effect of the restrictor valve inside the master cylinder), which can be a bit disconcerting! I get my assistant to press down hard on the pedal while I rapidly open and shut each caliper bleed nipple in turn. The much higher pressures, and hence flow when the bleed nipples are opened, seems to blast any remaining air out of the pipes. Thereafter the brakes have always been as expected.

Dual-circuit systems need special consideration as depressing the pedal with one circuit open and the other closed is likely to activate the 'imbalance' detector and bring up a warning light on the dashboard. The UK only got dual-circuit brakes at the same time as the master cylinder with servo, and on these the balance switch is under the master cylinder. This can be partially unscrewed, which although the warning light may come on as you depress the pedal (if the ignition were on) it will reset itself when you release the pedal, and you screw the switch back when you are finished. The problem comes with the earlier North American system that did not have the servo. On those the imbalance switch is on a separate manifold, and is not self-resetting. If the warning light is lit after doing both sides then get the assistant to apply medium pressure to the pedal, and on the side opposite to the one you did last, open the bleed nipple just a fraction letting a tiny dribble of fluid out. Get the assistant to shout as soon as the warning light goes out, and rapidly close the nipple. If it doesn't go out try doing it on the side you bled last.

Added October 2009: Following me giving the above advice about high-pressure bleeding on a mailing list a medic pal told me he had to do exactly the same thing with an arterial pressure measuring system. They had to get all the air bubbles out of the external tubing or it wouldn't work. The system came with a low pressure and flow flushing feature which was never sufficient, so they had to add a syringe to give a much higher pressure and flow which was successful in blasting them out. A 'negative' pressure system (akin to the Mityvac which some recommend for brake and clutch bleeding) was also of no benefit. A 'continuous flow' system would sometimes work, but on a car would need many litres of brake fluid to work, or a very long length of tubing from nipple back to master. This method (with a short length of tubing) can be used when bench-bleeding master cylinders by looping the outlet directly back into the reservoir. But bench bleeding has own problems of mess and potential for contamination and I've never bothered doing it.

Update May 2013: However after working on the calipers and brake pipes of Vee I just couldn't get rid of the long pedal, so had to resort to another method people mention from time to time, and that is wedging the brake pedal hard down overnight. Even that didn't work the first time, so the second time I jacked up the front (the principle of wedging down being that any air in the system will float to the highest point over time - hopefully the loop of pipe right by the master, then when the pedal is released the bubbles will be sucked back into the master reservoir), and after that it was OK. This brake work was done on my full-length ramps where the car was reversed on, and the construction of the ramps is such that even when fully erected the end you drive on is slightly lower than the other end, and even with the wheels off the nose of the car was slightly lower than the rear. So I suspect that was preventing my usual bleeding method from working first time rather than anything else.

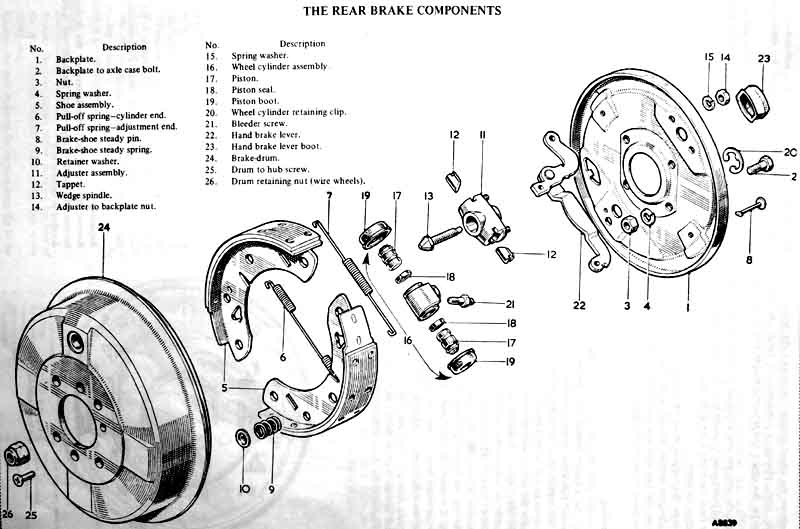

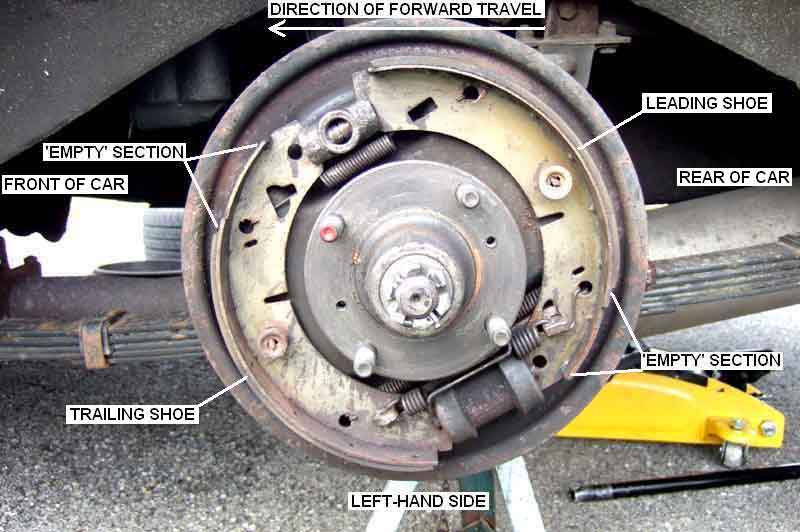

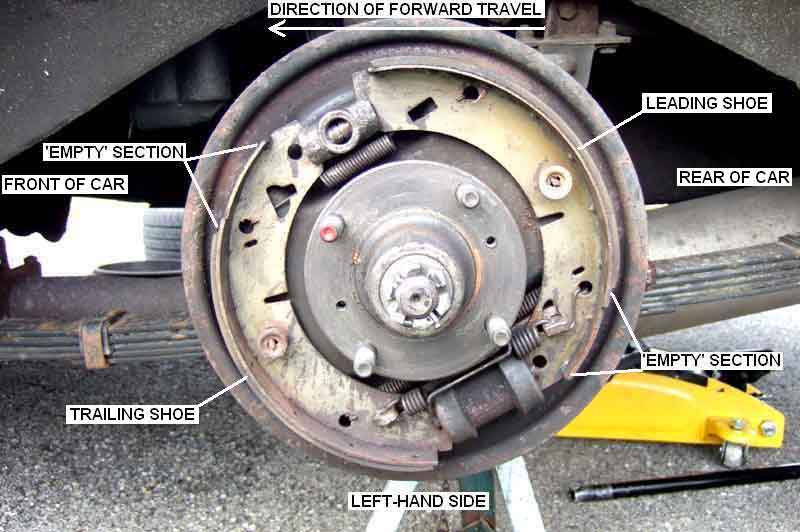

Although I have never experienced this problem on multiple BL cars I'll mention it anyway. People from time to time ask why the bleed nipple on the rear cylinders isn't at the top like it is on the calipers, and why doesn't an air bubble get trapped in them and cause spongy brakes. The reason is that a caliper is self-adjusting for wear and the pistons gradually move further and further out so creating a larger and larger cavity behind the piston for air to gather in. So unless the bleed point is at the top air will never be fully removed when bleeding. Look at the diameter of a caliper piston and how far it can be pushed back in when you remove worn pads and you will see what I mean. By contrast wheel cylinder pistons should be pushed all the way back in by the springs when the brakes are released and this leaves just a tiny channel round the backs of the pistons and not a cavity between the pistons to trap air. Normal bleeding will push air down and out of this tiny channel just like it will push an air-bubble downwards along a length of pipe. Adjustment for wear is on the separate adjuster at the top, of course, and doesn't affect the hydraulic system like it does with calipers. However when the handbrake cable is connected and correctly adjusted the handbrake levers will be holding the lower ends of the shoes further apart against the springs - just like the adjuster at the top, and hence the wheel cylinder pistons won't be pushed fully back into the cylinders. For this reason perhaps the handbrake should be released while bleeding the rears in order to push the wheel cylinder pistons further back, but short of disconnecting the handbrake cable in one side the difference will only be marginal, and in 35 years I have never found this to be necessary. A couple of people have mentioned that they have only been able to get rid of a spongy pedal by forcing the rear shoes to be locked on by the adjuster as this is the only way to force the wheel cylinder pistons fully in and so remove a larger space between the backs of the wheel cylinder pistons which is trapping air. If that is the case I'd suspect weak or missing return springs, or possibly stiffness in the handbrake cable or levers preventing the shoes from being pulled back by the springs, which could indeed leave more of a cavity that will trap air.

Persistent sponginess: August 2022: A couple of times now Jon Mould has mentioned on the MGOC forum that he had replacement calipers where the drillings between the two halves of the caliper were incomplete. The symptom was repeated bleeding got no more air out, but clamping off the hose (both hoses if both calipers replaced) got a hard pedal. He writes:

March 2022 Robin Guojah on the MGOC forum can't get a firm pedal after fitting a servo, fine if he bypasses it. He found a long video with a lot of waffle that basically just takes a tube from the nearest caliper back to the reservoir, so keeps recirculating fluid for as long as needed rather than running more and more through into a jar that is then discarded. Once the return tube has been filled and the master level checked you don't need to check any more until the end, and the only fluid 'lost' is what is in the return tube, but other than that it is no different to basic pedal bleeding (except you don't need to keep opening and closing the caliper nipple). After more than five minutes panning back and fore from the caliper to the master with the return tube already in place and without showing bleeding in progress he says that he 'eventually' got a firm pedal, but didn't say how long that took. And if the caliper nipple was wide open I wouldn't expect to get a firm pedal anyway. Maybe it was only partially open, so a combination of pressure and flow bleeding. Worth a try if really stuck, although Robin said it didn't work for him, maybe he didn't do it for long enough. The benefit of this method is that you can do it for as long as you have the patience and you aren't wasting more and more fluid. Maybe next time I'll try it in place of the high-pressure bleed just out of interest as it is another one-person process instead of a two-person.

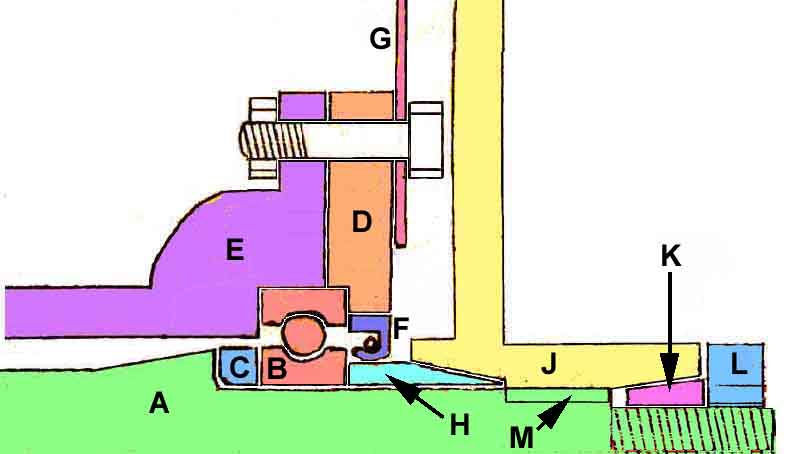

Neither did removing the air-valve piston and dribbling fluid in to try and remove the air that way. Eventually Robin bypassed the servo and Lo and Behold, no sponginess. This is the second new servo, remember. Got back to the supplier (MGBHive!) who said they would refund him, but asked that Robin speak to their 'technician' beforehand, waiting to hear about that.

Even more techniques were mentioned, so probably worth summarising them, roughly in order of how much messing about is needed:

- Firstly check the rear shoe and handbrake cable adjustment is correct, and see if the problem goes with the handbrake pulled up.

- For bleeding position the car with the front higher than the rear, and work round from the longest run to the shortest. Note that on RHD CB cars the shortest is front offside, but on RB cars where the front nearside comes direct off the servo that is the shortest.

- Pedal bleeding - opening the bleed nipple after pressure has been applied to the pedal, and only releasing the pedal after it has been tightened. Repeat until bored or no more air comes out. Speedbleeders make this a one-person (but expensive for what should only be used rarely) job.

- Gunsons EeziBleed - low pressure but continuous flow until no more air, which in my experience then needs the high-pressure technique below.

- High pressure bleed - after all four corners have been bled with one of the above techniques, but you still have the long pedal with the first press. 'Pump them up' to get a hard and short pedal, then press then down very hard on the pedal while someone else rapidly opens and closes a caliper nipple. Release the pedal, re-pump and press down again for the second caliper.

- Wedge the brake pedal down hard overnight after getting the long pedal. i.e. don't 'pump them up' to get a hard pedal and then wedge it down.

- Recirculation - take a tube from the nearest caliper and direct it into the master cylinder, making sure it cannot flip out dumping fluid everywhere. Slacken the caliper nipple a little, such that some fluid comes out when the pedal is pressed, but there is still resistance. Pedal bleed with firm pressure for as long as you have patience, or hear gurgling, tighten the nipple and try the pedal. Initial filling of the tube may need the master to be topped-up, but not after that. Only what is left in the tube will be 'lost' instead of several master-cylinder's worth.

- Gravity bleed - open each nipple in turn and allow it to drip into a jar while you get on with something else, in the hope that air bubbles will come down with the fluid. Check and top-up the level in the master cylinder periodically.

- Vacuum bleed - MityVac or similar. Note this will probably suck air past the threads so you may think it is continuously purging air from the lines when it isn't. Periodically close the nipple and try the pedal.

- Isolation - clamp off the rear hose (only if standard rubber). That will make the pedal a little higher, and if the pedal is now as it should be the problem is in the rear circuit. If you still get the long pedal that 'pumps up' it's not the rear circuit. Do the same with each caliper hose in turn, then both together. If one caliper gives the correct pedal it's that caliper. If clamping one reduces the problem and clamping both stops it then they are both causing it. Replacement calipers have been known to have the bleed passage between both halves blocked, trapping air. If you still get the long pedal with all three clamped up it's going to be somewhere in the pipe-work, if you have a remote servo then probably there.

- With the remote servo already fitted in the factory 'air valve facing up' position remove the air-valve piston, have someone press the brake pedal VERY slowly and carefully, with cloths all round, until fluid becomes visible. Then release the pedal very slowly while dribbling fluid in from a syringe to replace fluid as the level drops.

- Union bleeding - slacken various unions one at a time, with cloths to catch fluid, and do a pedal bleed in the hope of pushing air out that won't go all the way round the system to a bleed nipple.

- New/refitted servo - if fitting a servo, especially with pipes or if they are being replaced, fit it as per after-market instructions i.e. with the cylinder angled upwards, and the air-valve pointing downwards.

- Bypass the servo - if that solves the problem delete the servo altogether! The factory remote servo gave very little assistance anyway.

EeziBleed March 2016 A couple of things to watch out for.

The spare tyre is typically used to pressurise the reservoir and pressures of 15-20psi are banded about, which will almost certainly need you to reduce the tyre pressure from its normal level (and need reinflating afterwards). However I've found that even 15psi is too high, leaking from the reservoir cap seal, which rapidly deflates the tyre. 10psi is enough, you are never going to blast the fluid out with an EeziBleed, only trickle it out, so you might as well use the lower pressure.

November 2021: Watching a Caterham being built I noticed they used a pressure bleed system at 1.5 bar, which equates to 22psi.

I've had mine many years but quite soon after purchase I found that screwing on the reservoir cap too tightly caused the rubber ring seal inside to be forced down into the neck of the reservoir and no longer seal, which is another reason for using minimum pressure and not needing to screw the EeziBleed cap down as tightly. Over time the seal distorted badly and would not lie flat on the neck of the bottle, which meant it was always leaking even on low pressure which made bleeding a pain having to keep re-inflating the tyre. I contacted the manufacturer and they kindly sent me a replacement free of charge, so now I remove and wipe it in the hope that it retains its shape and function for longer.

Make sure the tube is securely fastened and sealed to the cap that you will be using, and the cap will seal to the master. The system works by pressurising the fluid, and hence the air, inside the master reservoir. If either the tube or the cap doesn't seal the air will leak out to be replaced by fluid, and hence overflow. A pal inherited a system from his pal where the tube was not sealed to the cap, and fluid went everywhere. There is a brass fitting with two fibre seals and a nut which seals itself to the cap, and the tube passes through this. Make sure the tube has an alloy tapered cylinder inside, and this part of the tube is wedged into the brass fitting, as this forms the seal between the tube and the fitting. Finally there is a rubber seal inside the cap which seals to the neck of the master cylinder. If any of these seals are inadequate fluid will leak out. Note that if the top of the neck of the master cylinder is damaged or distorted the cap may not seal and again fluid will leak out.

Make sure the tube is securely fastened and sealed to the cap that you will be using, and the cap will seal to the master. The system works by pressurising the fluid, and hence the air, inside the master reservoir. If either the tube or the cap doesn't seal the air will leak out to be replaced by fluid, and hence overflow. A pal inherited a system from his pal where the tube was not sealed to the cap, and fluid went everywhere. There is a brass fitting with two fibre seals and a nut which seals itself to the cap, and the tube passes through this. Make sure the tube has an alloy tapered cylinder inside, and this part of the tube is wedged into the brass fitting, as this forms the seal between the tube and the fitting. Finally there is a rubber seal inside the cap which seals to the neck of the master cylinder. If any of these seals are inadequate fluid will leak out. Note that if the top of the neck of the master cylinder is damaged or distorted the cap may not seal and again fluid will leak out.

Finally, before putting any fluid in the EeziBleed reservoir, connect it all up and check for leaks by listening for any hissing. If you can hear hissing from anywhere near the master cylinder fluid will leak out. Hissing from the EeziBleed cap threads will only flatten your spare tyre more quickly than it should, but if it is coming from the tube that leads to the master cylinder again that will leak fluid.

Brake Balance and Handbrake Warning

North American spec cars got the brake balance circuit with the dual-line braking system with the MkII in November/December 1967, and the handbrake warning circuit for the 1976 model year. Other LHD markets got both for the 1976 model year. The UK (and other RHD markets) didn't get any of dual-circuit, brake balance warning or handbrake warning until May 1977 mid-way through the model year.

North American spec cars got the brake balance circuit with the dual-line braking system with the MkII in November/December 1967, and the handbrake warning circuit for the 1976 model year. Other LHD markets got both for the 1976 model year. The UK (and other RHD markets) didn't get any of dual-circuit, brake balance warning or handbrake warning until May 1977 mid-way through the model year.

There were three arrangements of the brake balance failure circuit:

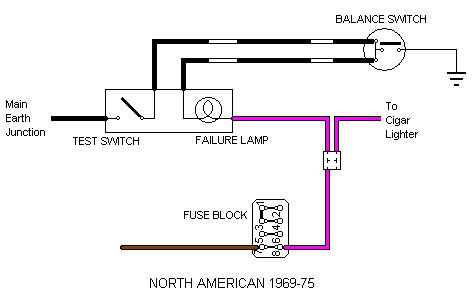

For North American Mk2 cars there was a warning lamp with a test switch that merely tested the warning bulb and its 12v supply. It has a single black/white wire running from the balance failure switch to one side of the failure warning lamp, the other side of the lamp being connected to the purple (always on, fused) circuit. A black earth wire was connected to one side of the test switch, the other side of the switch being connected to the same side of the lamp as the black/white wire. Balance failure results in a earth being connected to the black/white wire, which lights the lamp. The test switch merely connects a local earth to the warning lamp, the wiring to the balance failure switch could be disconnected but the test switch will still light the lamp.

For North American Mk2 cars there was a warning lamp with a test switch that merely tested the warning bulb and its 12v supply. It has a single black/white wire running from the balance failure switch to one side of the failure warning lamp, the other side of the lamp being connected to the purple (always on, fused) circuit. A black earth wire was connected to one side of the test switch, the other side of the switch being connected to the same side of the lamp as the black/white wire. Balance failure results in a earth being connected to the black/white wire, which lights the lamp. The test switch merely connects a local earth to the warning lamp, the wiring to the balance failure switch could be disconnected but the test switch will still light the lamp.

The 1969-75 circuit was a more comprehensive system where the test switch checked the wiring right back to and through the balance failure switch. It has two black/white wires running between the balance-failure switch and the warning/test panel, these two wires are linked together inside the balance-failure switch. In the warning/test panel one wire is connected to one side of the lamp, the other to one side of the switch. The other side of the lamp is connected to the purple circuit as before, and the other side of the switch is connected to a local earth as before. Balance failure results in a earth being sent from the balance switch down both wires. One will light the lamp, the other does nothing. However with this circuit when the test switch is operated a earth is sent up one wire, though the link inside the balance switch, and back down the other to light the lamp. This proves the continuity of the wiring between the switch and failure lamp as well as the failure lamp and power supply as before. I have also heard from one source that fluid leakage through the switch will cause the internal link to fail, which means the test will fail. However whether this was a 'one-off' or a design feature hasn't been confirmed. If it is intentional it seems to imply that leakage through the switch was almost expected (it certainly does seem to happen by all accounts), in which case one would have thought they would make a better switch!

The 1969-75 circuit was a more comprehensive system where the test switch checked the wiring right back to and through the balance failure switch. It has two black/white wires running between the balance-failure switch and the warning/test panel, these two wires are linked together inside the balance-failure switch. In the warning/test panel one wire is connected to one side of the lamp, the other to one side of the switch. The other side of the lamp is connected to the purple circuit as before, and the other side of the switch is connected to a local earth as before. Balance failure results in a earth being sent from the balance switch down both wires. One will light the lamp, the other does nothing. However with this circuit when the test switch is operated a earth is sent up one wire, though the link inside the balance switch, and back down the other to light the lamp. This proves the continuity of the wiring between the switch and failure lamp as well as the failure lamp and power supply as before. I have also heard from one source that fluid leakage through the switch will cause the internal link to fail, which means the test will fail. However whether this was a 'one-off' or a design feature hasn't been confirmed. If it is intentional it seems to imply that leakage through the switch was almost expected (it certainly does seem to happen by all accounts), in which case one would have thought they would make a better switch!

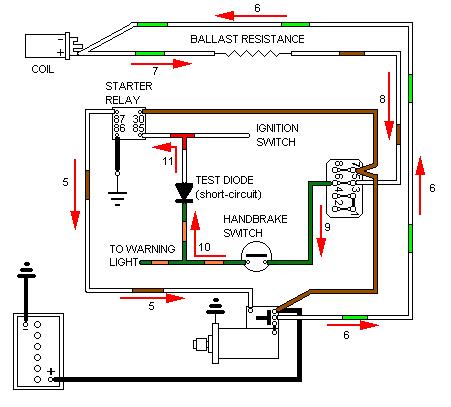

The 1976-on North American circuit is quite different, being integrated with a 'handbrake on' warning but deleting the manual test switch. Non-servo dual line systems had a remote splitter manifold containing the balance switch, servo dual-line systems had the balance switch as part of the master cylinder assembly. The drawing of the brake balance switch implies that a) the warning light would be on all the time, and b) in the event of balance failure the green circuit fuse would blow! I think both of these rather unlikely, and so have drawn the switch as I think it actually is. Note that this circuit contains a diode which if it goes short-circuit will cause the starter to crank as soon as the ignition is turned on ... and can't be stopped by turning it off again ... unless you drop the handbrake. Update October 2009 This master/servo unit is identical for both pre 76 and 76 and on, and new ones from Moss at least are supplied with the later switch in the box but not installed. For earlier cars with the white/black wiring the earlier switch must be used instead or the balance failure warning will not operate although the test circuit will. End of update. As said there is no longer a manual test switch, but there is a part of the circuit that will light the warning lamp every time the engine is cranked, so testing at least the lamp and its 12v supply is OK, which saves one the huge inconvenience of manually checking the circuit when one happens to think about it. But because the lamp also acts as a 'handbrake on' warning, and seeing as how on most occasions the handbrake will be on anyway when cranking the engine, the 'crank test' facility is almost entirely superfluous. Not only that but all either do is check the handbrake warning lamp and its local earth, it doesn't check the continuity of the balance switch wiring. Another example of interfering American legislators not really understanding what they were doing.

The 1976-on North American circuit is quite different, being integrated with a 'handbrake on' warning but deleting the manual test switch. Non-servo dual line systems had a remote splitter manifold containing the balance switch, servo dual-line systems had the balance switch as part of the master cylinder assembly. The drawing of the brake balance switch implies that a) the warning light would be on all the time, and b) in the event of balance failure the green circuit fuse would blow! I think both of these rather unlikely, and so have drawn the switch as I think it actually is. Note that this circuit contains a diode which if it goes short-circuit will cause the starter to crank as soon as the ignition is turned on ... and can't be stopped by turning it off again ... unless you drop the handbrake. Update October 2009 This master/servo unit is identical for both pre 76 and 76 and on, and new ones from Moss at least are supplied with the later switch in the box but not installed. For earlier cars with the white/black wiring the earlier switch must be used instead or the balance failure warning will not operate although the test circuit will. End of update. As said there is no longer a manual test switch, but there is a part of the circuit that will light the warning lamp every time the engine is cranked, so testing at least the lamp and its 12v supply is OK, which saves one the huge inconvenience of manually checking the circuit when one happens to think about it. But because the lamp also acts as a 'handbrake on' warning, and seeing as how on most occasions the handbrake will be on anyway when cranking the engine, the 'crank test' facility is almost entirely superfluous. Not only that but all either do is check the handbrake warning lamp and its local earth, it doesn't check the continuity of the balance switch wiring. Another example of interfering American legislators not really understanding what they were doing.

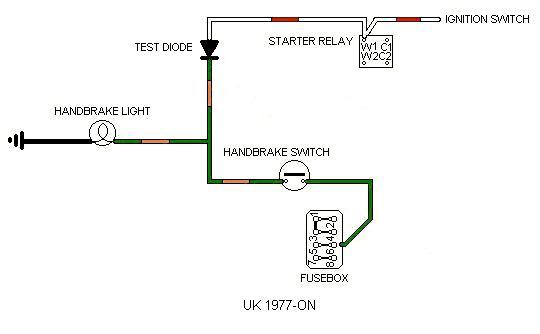

The 4th circuit is the 1977-on RHD/UK spec 'handbrake on' warning which seems different to US cars in that the UK schematics show no brake balance switch in circuit. But this must be an omission in the drawings as all the cars checked do have the switch and wiring. UK cars can also suffer from the 'continual cranking' problem described as above.

The 4th circuit is the 1977-on RHD/UK spec 'handbrake on' warning which seems different to US cars in that the UK schematics show no brake balance switch in circuit. But this must be an omission in the drawings as all the cars checked do have the switch and wiring. UK cars can also suffer from the 'continual cranking' problem described as above.

The handbrake switch in the above systems is AAU2492.

The handbrake switch in the above systems is AAU2492.

Info from Willy Revit in Tasmania is that when the boosted master balance valve has moved to one side or the other and latched it shuts off the fluid path which means that the pedal does not go down as far with one circuit failed as with the unboosted dual master, and maybe only for the first time the pedal is operated. That would complicate bleeding and is perhaps why one is supposed to unscrew the switch before bleeding, which prevents the shuttle valve from latching.

Continual cranking:

But the biggest problem with these latter circuits that include the handbrake warning is that they include a diode, which if it goes short-circuit causes the starter to crank all the time, unless one has the presence of mind to drop the handbrake! When I first looked into this, based on a description of the problem from someone who had it, I thought it didn't occur until you turn the key to crank, then it kept cranking. But in fact as Roger Parker points out in the October 'Enjoying MG' it starts cranking as soon as you turn on the ignition. You might think that by turning off the ignition you would stop it cranking. But no, once it starts, it keeps going until you either disconnect the battery, or pull the wires off the starter relay, or drop the handbrake. This is because even though you have turned off the ignition and apparently removed 12v from the white, white/brown and green ignition circuits, the starter solenoid is feeding 12v direct to the coil, which comes backwards through the coil ballast resistor onto the white/brown, and from there onto the green, then via the handbrake switch closed and the short-circuit diode to keep the starter relay operated, which is keeping the starter solenoid operated. Even though the current has to come through the ballast resistor there is relatively little voltage dropped across it, leaving more than enough to keep the starter relay operated.

But the biggest problem with these latter circuits that include the handbrake warning is that they include a diode, which if it goes short-circuit causes the starter to crank all the time, unless one has the presence of mind to drop the handbrake! When I first looked into this, based on a description of the problem from someone who had it, I thought it didn't occur until you turn the key to crank, then it kept cranking. But in fact as Roger Parker points out in the October 'Enjoying MG' it starts cranking as soon as you turn on the ignition. You might think that by turning off the ignition you would stop it cranking. But no, once it starts, it keeps going until you either disconnect the battery, or pull the wires off the starter relay, or drop the handbrake. This is because even though you have turned off the ignition and apparently removed 12v from the white, white/brown and green ignition circuits, the starter solenoid is feeding 12v direct to the coil, which comes backwards through the coil ballast resistor onto the white/brown, and from there onto the green, then via the handbrake switch closed and the short-circuit diode to keep the starter relay operated, which is keeping the starter solenoid operated. Even though the current has to come through the ballast resistor there is relatively little voltage dropped across it, leaving more than enough to keep the starter relay operated.

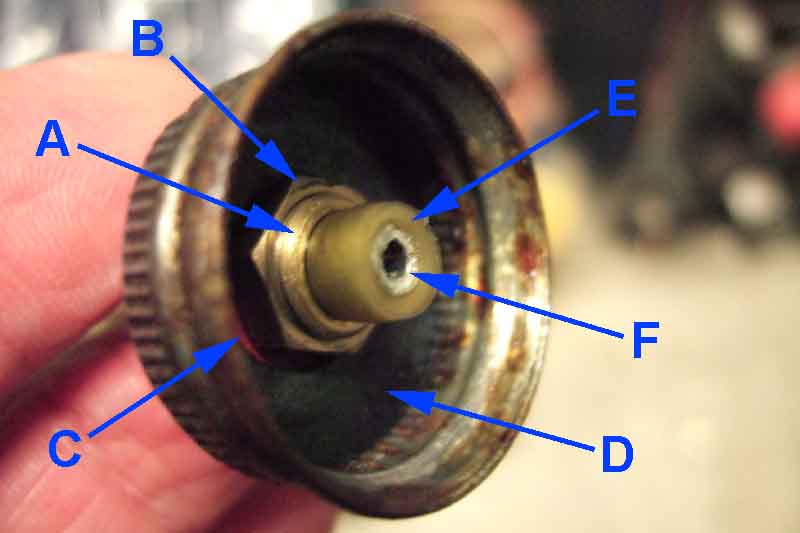

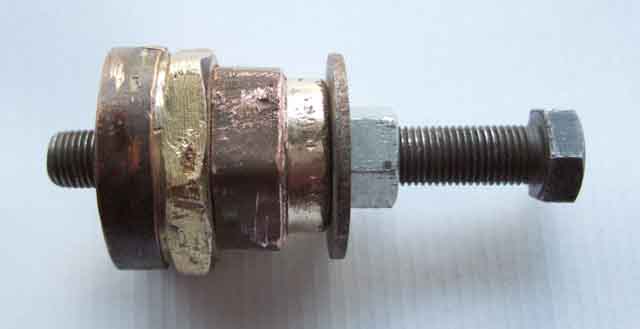

The diode is a cylindrical object (click the thumbnail for a picture) tucked high up behind the dashboard on the right-hand side in UK cars - labelled 'Pektron' with a diode symbol and 'A75-294', and I think US cars have them in the same location. It has a male spade for a female connector on the white/red feed from the starter relay, and a female spade for a male connector on the green/orange wires to the brake switch and warning lamp. If your diode fails short as a temporary measure disconnect the white/red from the diode, as the connector on that wire is insulated. If you remove the green/orange and don't tape it up you are more than likely to blow the green-circuit fuse. Part number AAU5034A available from several of the usual suspects, but you can replace it with any 1 amp 100v diode, with suitable male and female connectors on tails, connected the right way round!! Diodes usually have the positive end marked with a white band or '+' sign, this end connects to the green/orange wires and so needs a female spade connector.

The diode is a cylindrical object (click the thumbnail for a picture) tucked high up behind the dashboard on the right-hand side in UK cars - labelled 'Pektron' with a diode symbol and 'A75-294', and I think US cars have them in the same location. It has a male spade for a female connector on the white/red feed from the starter relay, and a female spade for a male connector on the green/orange wires to the brake switch and warning lamp. If your diode fails short as a temporary measure disconnect the white/red from the diode, as the connector on that wire is insulated. If you remove the green/orange and don't tape it up you are more than likely to blow the green-circuit fuse. Part number AAU5034A available from several of the usual suspects, but you can replace it with any 1 amp 100v diode, with suitable male and female connectors on tails, connected the right way round!! Diodes usually have the positive end marked with a white band or '+' sign, this end connects to the green/orange wires and so needs a female spade connector.

October 2016: Roger also points out that the same problem can occur when you aren't even in the car, from a slightly different cause, and that is when the seat-belt module fails in a particular way. This has connections to both the purple circuit (fused always live) and the white/red starter solenoid circuit. If a fault develops inside the unit, or from faulty wiring, that connects the purple and the white/red wires together, then the starter solenoid will engage. The engine will try to start, as with the same sequence of events as above the ignition system will be partially powered, and as if thing weren't bad enough if left in gear the car will try to crank itself along. This usually damages the starter motor at least, and is a good advert for having a battery cut-off switch - and turning it off when garaged if not at other times. Roger does say that other components like the ignition switch or starter relay and wiring can cause the same problem, but that won't happen in the middle of the night. Oh contraire! Maybe not the middle of the night, but some years ago a neighbour's ancient Transit van started cranking while parked - left in gear, and crossed three front gardens before we could get hold of him to stop it.

Fault Diagnosis:

US 1968 circuit: If the light doesn't work from either the test switch or the balance switch either the 12v supply from the purple circuit is missing or you have two or more faults like power supply, earth supply, bulb blown, switch(es) faulty. If it lights from the test switch but not the balance switch either the balance switch is faulty or the wiring between the two is faulty. To eliminate this last possibility disconnect the wiring from the switch and connect a known good earth to the wiring connector. If it lights from the balance switch but not the test switch either the earth supply to the switch is faulty or the switch itself.

US 1969-75 circuit: If the light doesn't come on from either the test switch or the balance switch either you have two or more faults like power supply, earth supply, bulb blown, switch(es) faulty, or there is a disconnection in the wiring between the balance switch and the warning/test panel. If connecting a known good earth to both black/whites at the switch/light panel doesn't light the lamp either the bulb is faulty, it isn't making good connection with the bulb holder, or there is no 12v supply to one side of the bulb. If that works but not if you earth both black/whites as the master then there is a break in at least one of the black/whites between the master and the switch/lamp panel. This could be at the multi-plug behind the dash (later cars) or a pair of single connectors in the black/whites (earlier cars). If that works, link the two black/whites in the plug that goes on the balance switch and try the test switch. If that works the balance switch is faulty or not being operated by the shuttle valve inside the master. If the test switch still doesn't light the lamp the switch itself could be faulty, or its earth supply, or there could be a break in its black/white between the test switch and the balance switch connector. Note that the balance switch will only light the warning lamp if it is attached to the master, or has an alternative earth provided to its body. It won't light the warning lamp if it is removed from the master, even though it has two wires on it. However when the balance switch is removed from the master cylinder, the test switch should light the warning lamp as long as the wiring is connected to the balance switch and the rest of the circuitry is correct.

US 1976-on circuit: This circuit works 'the other way round' to the earlier circuits by extending a 12v signal from the balance switch, handbrake switch or test diode to the warning lamp, which is backed by a local earth. If none of them causes the lamp to light either the bulb has blown, its local earth is faulty, or the green/orange wire to it has a disconnection. If the handbrake switch lights the lamp but cranking (handbrake down) and balance switch do not then there is probably a disconnection in the green/orange between test diode and handbrake switch. If the handbrake and cranking lights it but the balance switch does not then either the balance switch is faulty, the green orange between it and the test diode has a disconnection, or the green 12v supply to the balance switch is disconnected. If the balance switch lights it but either or both of cranking or handbrake do not, then in the former case the test diode or its white/red connection to the starter relay is open-circuit, and in the latter the handbrake switch is faulty, incorrectly adjusted, its local harness disconnected, the green 12v supply to it disconnected, or something is preventing the handbrake from fully returning to the 'off' position.

UK 1977-on circuit: This circuit works 'the other way round' to the earlier circuits by extending a 12v signal from the handbrake switch or test diode to the warning lamp, which is backed by a local earth. If neither of then causes the lamp to light either the bulb has blown, its local earth is faulty, or the green/orange wire to it has a disconnection. If the handbrake switch lights the lamp but cranking (handbrake down) does not then there is probably a disconnection in the green/orange between test diode and handbrake switch. If the handbrake lights the lamp but cranking does not then the test diode or its white/red connection to the starter relay is open-circuit. If cranking lights it but the handbrake does not either the handbrake switch is faulty, incorrectly adjusted, its local harness disconnected, the green 12v supply to it disconnected, or something is preventing the handbrake from fully returning to the 'off' position.

Rear hose

As brake hoses deteriorate flaps of rubber can start to become detached inside the hose and act as a check-valve. This can either reduce braking effort on one side, or cause the caliper on one side to stick on. If slackening the bleed screw on the stuck side causes a spurt of fluid after which the disc can be rotated, then the hose should be replaced. If there is no spurt of fluid, or only one piston of the pair is sticking, then the caliper itself is suspect.

If both rear brakes stick on then again it could be that hose. But if all four stick on and you have a servo then there are a couple of causes from that.

Whether you have a servo or not it could be the master cylinder piston not coming back far enough to clear the bypass port (or it is blocked), and if an RB it could be the mechanical brake light switch is not adjusted correctly.

Should you fit steel braided hoses? "If they are good enough for aircraft they are good enough for my MGB" well, yes, but only if you are going to replace them on a routine basis like they are on aircraft - you can't see what is happening to the rubber under the stainless braiding! (However I was assured when buying a set (not by choice) in 2013 that they are not rubber but Teflon and shouldn't degrade). They may well give a harder pedal by not swelling under heavy braking, hardly a factor in road cars I would have said (and if you have silicone DOT5 brake fluid that is more compressible than any of the non-silicone types).

Front hoses July 2019 Originally GBH109 changing to GBH158 (Parts Catalogue, no change point), then GBH172 in December 1975. Perusing Clausager he says there was a change to anti-torsion hoses for the V8 in May 74 (i.e. CB), and to 4-cylinder cars in May 75 (i.e. RB), which may equate to the earlier change. The December 1975 change at chassis numbers 394301 and 2708 was for armoured hoses. Suppliers show GBH158 for CB and GBH172 for RB, but from the above that's not really correct, and all cars would probably benefit from the later armoured hoses.

A question on a forum about hoses being too tight, from someone who had problems with replacements several years ago but managed to get a set of his original length from a specialist, and who suspects he is going to get the same problem again. Measuring his 'long' ones on car as best he can comes to 352mm from hex face to hex face (i.e. bracket to caliper, ignoring threads). Measuring mine on the roadster the same way (replaced at some point, part number not known) comes to 320mm as far as I can judge so quite a bit shorter, but gently curved none-the-less. The V8 (braided) are a bit longer at about 335mm, but seems a little tighter. This V8 Register document also shows a very tight hose (unarmoured), and checking a variety of replacements found them with metal ends (excluding the thread) of 25, 27, 30, 32 and 33mm length. Now the longer the metal end, the less hose there will be for a given length from hex face to hex face, will impact on how 'tight' it will get on a given steering lock. The roadster metal ends are 22mm and 25mm so at the bottom of that range, but the V8 are 33mm so at the top end, and explains why the apparently longer hose looks tighter. You also need to check both sides - or at least how many turns from straight-ahead to each lock (a shade under 3 1/2 on both mine and the original poster of the problem) - in case the rack isn't centralised, which will mean that one hose will be tighter than the other on full lock. It would also be worth measuring 'line of sight' from some point on the bracket to some point on the caliper in case there is some oddity with either of those.

A question on a forum about hoses being too tight, from someone who had problems with replacements several years ago but managed to get a set of his original length from a specialist, and who suspects he is going to get the same problem again. Measuring his 'long' ones on car as best he can comes to 352mm from hex face to hex face (i.e. bracket to caliper, ignoring threads). Measuring mine on the roadster the same way (replaced at some point, part number not known) comes to 320mm as far as I can judge so quite a bit shorter, but gently curved none-the-less. The V8 (braided) are a bit longer at about 335mm, but seems a little tighter. This V8 Register document also shows a very tight hose (unarmoured), and checking a variety of replacements found them with metal ends (excluding the thread) of 25, 27, 30, 32 and 33mm length. Now the longer the metal end, the less hose there will be for a given length from hex face to hex face, will impact on how 'tight' it will get on a given steering lock. The roadster metal ends are 22mm and 25mm so at the bottom of that range, but the V8 are 33mm so at the top end, and explains why the apparently longer hose looks tighter. You also need to check both sides - or at least how many turns from straight-ahead to each lock (a shade under 3 1/2 on both mine and the original poster of the problem) - in case the rack isn't centralised, which will mean that one hose will be tighter than the other on full lock. It would also be worth measuring 'line of sight' from some point on the bracket to some point on the caliper in case there is some oddity with either of those.

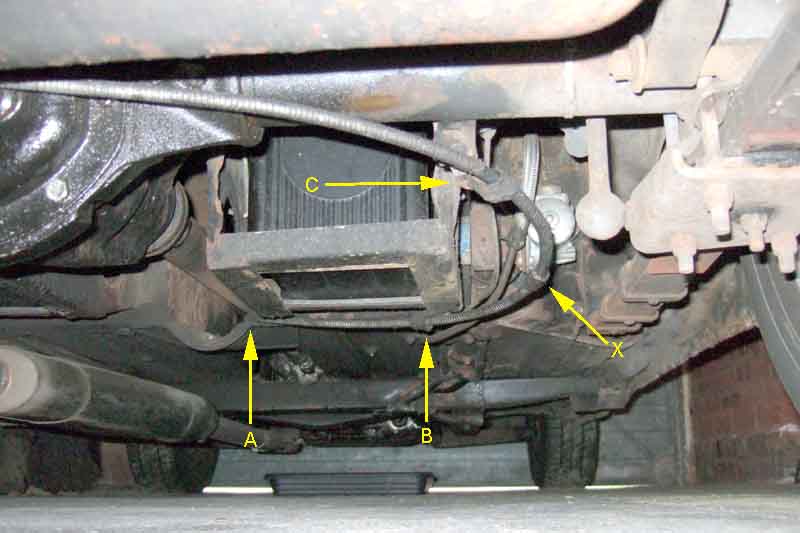

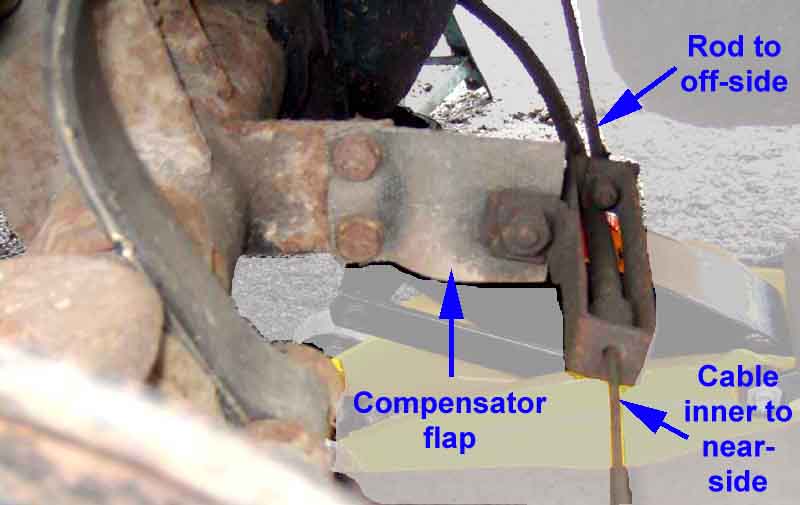

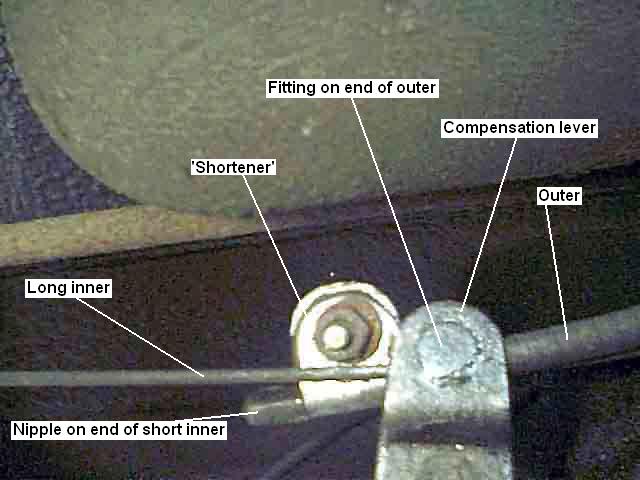

Rear hose January 2019

Originally the body pipe points backwards to connect to the hose, in a bracket welded to the side of the battery case, and the hose is curved back and down to the top of the union on the axle. But on 77-on cars with the factory anti-roll bar the union has to be positioned closer to the diff. The body pipe points downwards to connect to the hose, in a bracket bolted to the rear of the battery box, and the hose is curved down and across to the off-side port of the union, with the off-side pipe coming off the top port. It's important that the hose can cope with full travel of the axle without being stressed.

Originally the body pipe points backwards to connect to the hose, in a bracket welded to the side of the battery case, and the hose is curved back and down to the top of the union on the axle. But on 77-on cars with the factory anti-roll bar the union has to be positioned closer to the diff. The body pipe points downwards to connect to the hose, in a bracket bolted to the rear of the battery box, and the hose is curved down and across to the off-side port of the union, with the off-side pipe coming off the top port. It's important that the hose can cope with full travel of the axle without being stressed.

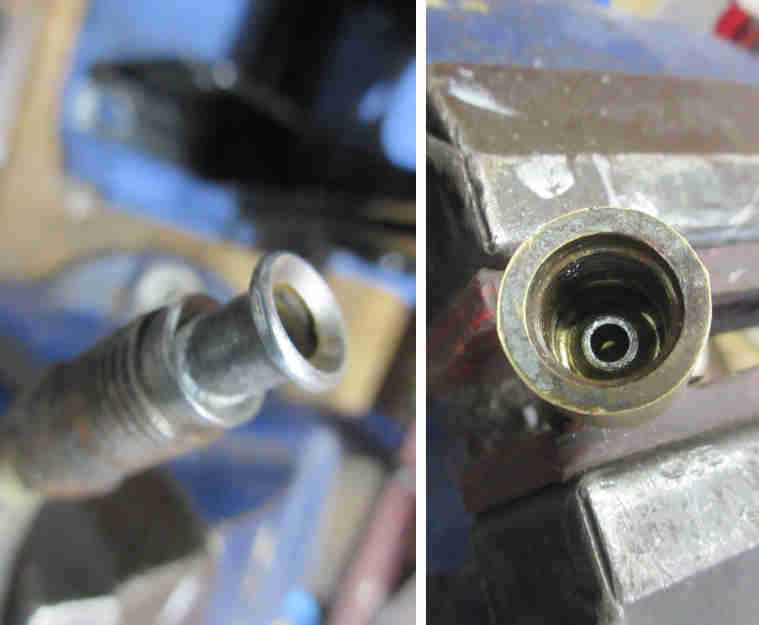

Note that the union changed at the same time. Originally 3H2424 only had the top port with a machined face for the hose seal, for 1977-on BMK1833 had all three ports machined as the hose enters one of the side ports, but only one type is shown for the MGB by suppliers today. Motaclan (Leacy) picture 3H2424 at £7.50 (albeit out of stock) with one extended port with a machined face and a recessed thread which would be at the top for the hose. The other visible port is shorter with the thread to the end, although the face does seem to be flat. Moss have pointed me at BTB657 which shows the threads recessed on at least two of the ports, which are longer, and appear to have machined faces, at £17! AJA5028 has also been mentioned which B&G show for the MGA but that could have four ports (or one blanked off) and whilst one of the others does seem to be longer and have a recessed thread with a machined face the other visible port is completely different. And whilst Rimmers references both 3H2424 and BMK1833A quoting the correct change point the latter comes up has having been superseded by 3H2424 But pictures are often just representative or of old stock and may not be an exact depiction of current stock. Definitely a case of buyer beware if you need one for a 77 or later axle.

Note that the union changed at the same time. Originally 3H2424 only had the top port with a machined face for the hose seal, for 1977-on BMK1833 had all three ports machined as the hose enters one of the side ports, but only one type is shown for the MGB by suppliers today. Motaclan (Leacy) picture 3H2424 at £7.50 (albeit out of stock) with one extended port with a machined face and a recessed thread which would be at the top for the hose. The other visible port is shorter with the thread to the end, although the face does seem to be flat. Moss have pointed me at BTB657 which shows the threads recessed on at least two of the ports, which are longer, and appear to have machined faces, at £17! AJA5028 has also been mentioned which B&G show for the MGA but that could have four ports (or one blanked off) and whilst one of the others does seem to be longer and have a recessed thread with a machined face the other visible port is completely different. And whilst Rimmers references both 3H2424 and BMK1833A quoting the correct change point the latter comes up has having been superseded by 3H2424 But pictures are often just representative or of old stock and may not be an exact depiction of current stock. Definitely a case of buyer beware if you need one for a 77 or later axle.

V8 pads

V8 pads in 4-cylinder calipers

Be aware that manufacturers vary in what they include with replacement pads in terms of whether anti-squeal shims, retainer springs and split pins are included or not.

Also be aware that it is possible to fit the pads 'upside down' i.e. with the tabs facing in towards the spindle and not out towards the retaining springs! As one owner found a PO or mechanic had done to his car.

Retaining springs:

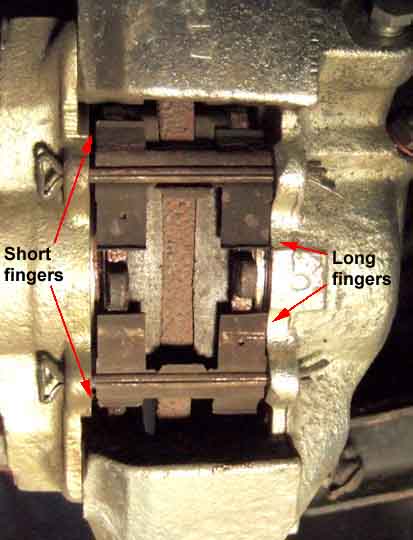

The pad retaining springs on both 4-cylinder and V8 calipers are 'handed' in that the fingers on one side are longer than the other. They can be made to fit either way, but the correct way is with the longer fingers on each retainer facing each other.

The pad retaining springs on both 4-cylinder and V8 calipers are 'handed' in that the fingers on one side are longer than the other. They can be made to fit either way, but the correct way is with the longer fingers on each retainer facing each other.

V8 pads:

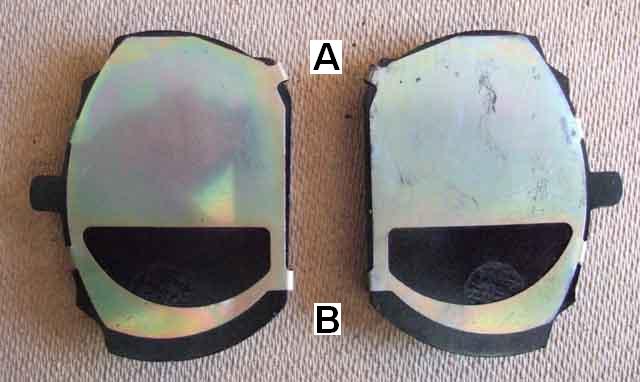

V8 pads are handed, but not 4-cylinder pads. Not right to left, but inner and outer. The pad almost fits in the 'wrong' half of the caliper but not quite, and it is very annoying when you buy a set, get them and home and start to fit them, then discover you have three inners and one outer as has happened to me! This is apparently because they have a mix of MGB Triumph 2.5 saloon components. The most recent set purchased have heavy chamfers on both edges, probably to try and deal with brake squeal.

V8 pads are handed, but not 4-cylinder pads. Not right to left, but inner and outer. The pad almost fits in the 'wrong' half of the caliper but not quite, and it is very annoying when you buy a set, get them and home and start to fit them, then discover you have three inners and one outer as has happened to me! This is apparently because they have a mix of MGB Triumph 2.5 saloon components. The most recent set purchased have heavy chamfers on both edges, probably to try and deal with brake squeal.

V8 pads in 4-cylinder calipers: December 2021

Yes they fit, without the complication of the handing, and do have a larger friction surface. It's the same at the outer edge of the caliper and the same overall width but it extends further towards the stub-axle, and has squarer corners there, both of which increase the potential surface area. But by bearing on a previously unused portion of the disc either new ones or having old ones skimmed may be required. If bigger pads are using a 'crusty' part of an old disc then braking effort will be significantly affected, worse than simply replacing pads like-for-like.

Yes they fit, without the complication of the handing, and do have a larger friction surface. It's the same at the outer edge of the caliper and the same overall width but it extends further towards the stub-axle, and has squarer corners there, both of which increase the potential surface area. But by bearing on a previously unused portion of the disc either new ones or having old ones skimmed may be required. If bigger pads are using a 'crusty' part of an old disc then braking effort will be significantly affected, worse than simply replacing pads like-for-like.

There is also the question of the available area on the disc for pad contact. 4-cylinder and V8 discs are different, do the former have the increased surface for the extra pad material to act on? And the answer is 'yes and no'. On the outer face of the disc some of the extra V8 pad material is overhanging the inner edge of the pad contact area, and on the inner face it isn't. So as well as having to do some dismantling to clean up the extra areas on the disc there will also be unbalanced braking between sides. That may be a factor in warped discs that one person apparently experienced with V8 pads in a 4-cylinder.

There is also the question of the available area on the disc for pad contact. 4-cylinder and V8 discs are different, do the former have the increased surface for the extra pad material to act on? And the answer is 'yes and no'. On the outer face of the disc some of the extra V8 pad material is overhanging the inner edge of the pad contact area, and on the inner face it isn't. So as well as having to do some dismantling to clean up the extra areas on the disc there will also be unbalanced braking between sides. That may be a factor in warped discs that one person apparently experienced with V8 pads in a 4-cylinder.

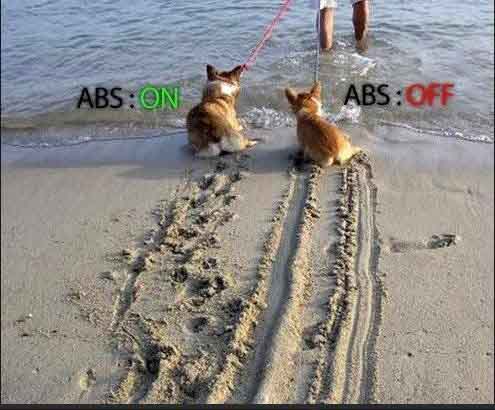

And to what end? No matter how powerful you make the brakes it's the tyre contact with the road that stops you. As long as you can lock the wheels the brakes are good enough, increasing the friction there only results in a lighter pedal pressure. If you do something to the front brakes that reduces pedal pressure in the MGB systems you are effectively reducing braking effort at the rear, which will extend your stopping distances, you would need to increase the tyre to road friction to stop sooner. Competition use aside if you need lighter brakes then fit a bigger servo, at least that will maintain the front to rear balance. It just goes to show yet again that when you start fiddling with what the factory did you almost always introduce compromises. As Roger Parker wrote in the MGOC magazine in May 2016 in an article entitled "Uprated Brakes - Do I actually need them" repeating it in January 2022 his conclusion was that in most cases uprated components were NOT needed for the type of use to which the cars were usually subjected. The 2022 article was primarily about brake squeal, which is often caused by uprated pads and discs, and other sources say the same thing. He does however show pictures of V8 pads in the January 2022 article indicating they can be used in 4-cylinder cars, I've sent him my findings.

Brake Pipe Change May 2013

As far as bending goes Fuzz Townshend uses a very nifty tool here - basically just a pair of pliers with curved jaws to grip the pipe, then you form the bend with your other hand. Originally I wasn't able to locate that one, but others of a similar type are only a couple of quid cheaper than the more sophisticated type where the second arm of the tool is used to make the bend, from less than a tenner, so I wondered if it is worth it. Then I happened to find it manufactured by Oakes for £19!! However the tool Fuzz uses is making a tighter bend, closer to the end, than the others are perhaps capable of.

For a while now I've been aware of Vee's right front brake pipe being rusty (the left front looks like it had already been changed) and last year I got an advisory on it, so decided to change it before the MOT this year. Came off OK, but straightening out where it passes under the chassis rail to remove it maintaining as much of the shape as possible to bend the new pipe to match, it cracked where it was obviously paper-thin. The new pipe went in OK with almost nothing lost from the union, and that was where the problems started!

Went to undo the caliper bleed screw and it was stuck fast, I could tell it was twisting. Tried releasing fluid - no go. Took it off and went to Halfords where they go some heat on it - still no go and it sheared. Back home I drilled the old one out, increasing the drill size bit by bit (no pun intended) hoping to get to the point where I could remove the remainder without damaging the threads, but by the time it did come out I had removed the top of the threads on one side of the hole. It might have been OK, but I didn't want to risk it, so I'll have to spring for a new one. Better check the other side, and that is exactly the same! Very annoying as I'd replaced these myself in 1997. So two calipers required, and might as well change the hoses as well even though I'd also replaced them in the past. Heavy items so cost is an issue, but I was going over to Shropshire in a couple of days so a detour to Clive Wheatley was the best way. Clive didn't have standard brake hoses but did have braided Teflon at not that much more as they were old stock.

Right-hand caliper and hose goes on OK, but although I can undo the pipe nut from the hose end on the left side, the nut is seized to the pipe, so I've had to unscrew the caliper and the hose from the pipe rather than the other way round. I could screw the new ones back on the same way, but might well end up with a twist in the hose, so decide to replace the left front pipe as well (this is getting into Shipwright's Disease territory). And of course the screw that holds the clip to the inner wing is seized and has to be drilled out, whereas both screws under the chassis rails where the clips were more rusty came out OK. Subsequently with the pipe held in a soft-jawed vice I can tap the nut up the pipe and free it up, so that is ready to be used as a spare, probably many years hence! Eventually I get pipes, hoses and calipers fitted both sides, and as the braided hose kit came with the rear hose as well decide to try changing that. And of course the main line to the union on the rear axle is also seized to its pipe! But as that doesn't need changing (yet!) I decide to leave that for another day as Vee has been out of action for several days already. Because of the problems with undoing them - and this only seemed to affect the replacement copper-coloured pipes - I put a smear of copper-grease where the pipes exited the nuts being careful to keep it away from the threads never mind the ports, to hopefully prevent a recurrence

So time for bleeding, and that is where more problems started. Bled low-pressure first, all four corners, longest to shortest, which left a long and spongy pedal as expected. Got my assistant to stand on the pedal as usual while I opened and shut each caliper nipple, but instead of more air after which the pedal is as it should be as in the past I just get fluid, and the pedal is no better. Do the same at the rears, with the same result. Same at the front again, still the same result. Getting a bit annoyed now, so leave it to ponder a bit, and remember some people recommend wedging the pedal down overnight. Do that and next morning it seems OK, and on a short test drive, but next day it is as bad as ever. Thinking about the theory behind wedging the pedal, I wonder if it is that under pressure any air bubbles will be compressed and knocked off the wall of the pipe, to float to the highest point. If this is the loop of pipe right by the master, then perhaps the back flow on releasing the pedal flushes them into the master and then the reservoir. So this time I jack the front of the car right up, and wedge the pedal overnight again. Next morning it is much better, but still a little long and a little spongy, and without the initial bite that I'm used to on both cars. This may be because of the new calipers - perhaps the pads having the bed-in again, I did notice the old ones had the cut-outs in the piston facing a different way to how they should be (facing towards the stub-axle) on at least one of them. I decide to leave things how they are and see what happens, and after a couple of weeks either I've got used to it or they have got back to normal.

As part of Vee's repaint and engine rebuild I stripped the engine bay including removing all the hydraulics. After they and the engine and gearbox had gone back in I reverse filled/bled the clutch and got full travel straight away, and with the brakes it was just the usual high-pressure bleed after filling the system then an overnight wedge-down of the pedal.

Brake Pipe Heat Shield December 2020

AHH8900, mounted in front of the heater using the middle and right (as you look in from the front) heater mounting screws on top of the heater flange. Why the brake pipes need shielding (it's described as such in the Parts Catalogue) is anyone's guess, if the fluid boils there the car is on fire! Some call it a fuel pipe shield which might make more sense except that the fuel pipe is above the shield, and it only seems to have been used on HS-equipped 4-cylinder cars. It makes more sense that it is a fuel pipe support, as on HS cars just after the support the pipe connects to the flex hoses that go to the carbs which are subject to engine rock. On HIF cars the fuel pipe has more clips further round the engine bay, and on the V8 the fuel pipe is even closer to the engine and unshielded. On both those the brake pipes go over the heater. More of a physical shield against the engine coming back? But then in an impact big enough to do that you aren't likely to need the brakes any more!

AHH8900, mounted in front of the heater using the middle and right (as you look in from the front) heater mounting screws on top of the heater flange. Why the brake pipes need shielding (it's described as such in the Parts Catalogue) is anyone's guess, if the fluid boils there the car is on fire! Some call it a fuel pipe shield which might make more sense except that the fuel pipe is above the shield, and it only seems to have been used on HS-equipped 4-cylinder cars. It makes more sense that it is a fuel pipe support, as on HS cars just after the support the pipe connects to the flex hoses that go to the carbs which are subject to engine rock. On HIF cars the fuel pipe has more clips further round the engine bay, and on the V8 the fuel pipe is even closer to the engine and unshielded. On both those the brake pipes go over the heater. More of a physical shield against the engine coming back? But then in an impact big enough to do that you aren't likely to need the brakes any more!

Brake squeal seems to have been a problem for the last 30 years. When I started getting it the word in the industry was that different asbestos was being used which had a lower wax content. Whatever, even anti-squeal shims and caliper piston cut-outs aren't guaranteed to cure it. I put a very thin smear of grease on every metal-to-metal contact point of pads/shoes, shims, pistons, calipers, back-plates etc. of both front and rear brakes and it seems to do the trick. Just once when first fitting new pads seems to be enough, but at every service for the rears. This used to cause some amusement amongst my friends many years ago but now one can buy brake grease for this very purpose. Be very careful not to get any on the friction material, discs or drums though. Generally successful for many years, I started getting one rear brake squealing on Bee which was very annoying on club runs with lots of short distances between turns. Greasing the shoes as above only worked for a short time and it came back. Eventually I swapped the shoes between the sides and the squeal went and hasn't returned so far after several years and thousands of miles.

After replacing Vee's calipers in April 2013 above I refitted the 'old' pads as they were nearly new, and after a short while started getting squealing from them. It started getting worse, so I removed the pads and greased them as I would new pads, and all seems OK since.

August 2014: At least, I thought it was. I've had to regrease them again since then, and now it is doing it again, in stop-start traffic they can really shriek. Googling brings up loads of problems and not a few remedies. One is chamfering the edges, and indeed when replacing the ZS discs and pads I was surprised to see a huge chamfer at a shallow angle and for more than half the thickness. A couple of YouTube videos showed people putting a chamfer of no more than about an eighth of an inch on them, which didn't seem much use to me. So I took mine out and using an angle-grinder cut a 45 degree angle for about half the thickness (still barely worn) on just the leading edge. I say 'edge' but it's radiused, so I cut the chamfer to the same radius. Subsequently a set purchased for the V8 is already chamfered. I checked the anti-squeal shims for orientation, and the cut-out was towards the leading edge, which is logical as that should mean the piston puts more pressure on the trailing edge. But note that with the V8 because the pads are handed - inner and outer - and the shims are also handed, you cannot get them facing the wrong way. However I did notice that the leading edge seemed to be worn more than the trailing, which goes counter to the logic of the shims, but then maybe they would have worn even more without them. The cut-outs in the pistons were facing the spindle as given in the manuals, but even that varies, sometimes even for other classic MGs, where recommendations can be that they should face down in the MGA but the other way in the Midget! (MG-Cars.net, about 3/4 the way down).

The backs of the pads were still well (copper) greased, but I did notice that the side edges of the backing plates were very shiny, so it's quite probable it's that part that is vibrating against the caliper. Nevertheless I didn't regrease them as I want to check the efficacy or otherwise of the chamfering. Reversed off the drive and a slight squeak when I braked, but then I had only chamfered the leading edges. After a couple of miles no squeaking, whereas unmolested they had been squealing within yards at the end of the road, and at the road humps and the end of the next road. However back again and pulling up outside another slight squeak, so the jury is still out. If that doesn't work there is talk of using specialist adhesives (but they only seem to be available from America with horrendous postage), or adhesive shims in place of the standard metal ones, or it might be 'Wurth' trying a specialist brake paste.

After just a couple more short journeys they are squeaking as bad as ever so chamfering is no good. Rather than use the Wurth paste which is just a different type of lubricant, I did more research and found Bremtech self-adhesive shims to replace the metal shims (also from Mintex and EBC). Removed (but kept!) the metal shims, cleaned all the grease off the pads with brake cleaner, used the pad as a template to cut the self-adhesive shims to size, peeled off the backing, and stuck down. Refitted and wheels back in about an hour. First journey of a few miles on local roads to a pal's house was blissfully silent, but then leaving his house they were at it again at the end of his road. After another local journey they are as bad as ever - squeaking occasionally but when they do it is pretty loud.

So the next step is to use the offcuts from the self-adhesive shims to stick onto the trailing edge of each backing plate, the principle being to cushion that from the face of the caliper that the pads are pushed against under braking. The left hand pads have the shiniest edges, which is interesting given that the squeal seems to be coming from that side, and when I'm turning the wheel to undo the nuts it's even squeaking slightly then. A strip on the worst edge still leaves the pads a little loose in the calipers, so I put some down the leading edge as well, which makes them snug. Back on the road and less than 8 miles round local roads and they are squealing again!

Next step is to try some CRC Disc Brake Quiet, which is reputedly a 'Paste that cures as a tough rubber. Prevents and stops disc brake noise and vibration.', or possibly Wurth Brake Paste. However a few more trips with the self-adhesive shims and extra strips shows that squeal is only happening occasionally, and not as loud as before, so I'll leave things as they are for a while. And eventually I realise they are not squealing any more.

Another recommendation is circular shims with prongs that go inside the piston, like these that come with MG/Rover ZS front pads (but not Mintex, for example), and some Peugeot pads, I understand.

Another recommendation is circular shims with prongs that go inside the piston, like these that come with MG/Rover ZS front pads (but not Mintex, for example), and some Peugeot pads, I understand.

November 2016: Still quiet (ditto October 2018, and after a flurry of reports earlier in the year and me recounting this trick, several other said it worked for them as well, and things have gone quiet (ho ho) since). But two more possibilities have come my way recently.

In May it happens again, this time accompanied by a vibration I could feel in the steering wheel. Got the front up, lock to lock no rubbing. Wheels off inspected lock to lock no signs of rubbing and nothing else obvious. Testing moving slowing forwards first one lock then the other it will very occasionally do it on both sides, trying it with brakes on and brakes off, but it's so infrequent and brief it's not been possible to establish the exact conditions necessary. Also took the rear drums off, clean and dry this time, although there is slight dampness round the off-side hub nut, and where the drum bolts up to the hub flange, which does smell very faintly of diff oil this time. Could be coming from the oil seal, but I'd expect that to run down the back-plate. The back of the hub is black and greasy, but not 'wet' with oil. Cleaned that off as well as round the hub nut and drum and hub flanges.

By November I'm pretty sure it has done it since May, but so wet lately Vee has had very little running. Drum off, no sign of oil, just some dry black marks on the areas of the drum and shoes, and only the slightest glistening on the hub and that face of the drum, all cleaned off with brake cleaner. The oil may have been from excess greasing at each annual service ... but why only one rear brake out of four? The graunch (if still there) remains to be found.

Piston cut-outs June 2018

When exercising and polishing the pistons solved a problem

And when it didn't Added May 2009

Disc changing

V8 calipers

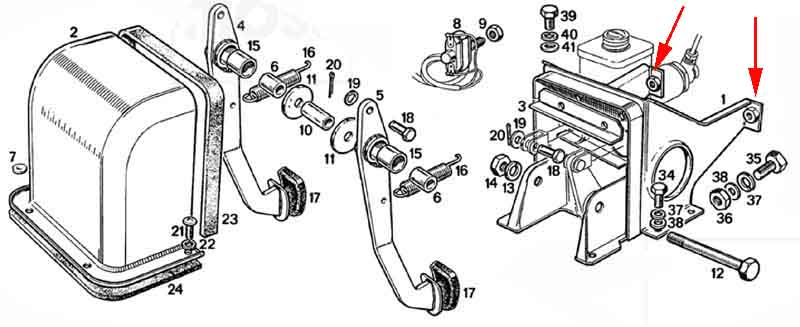

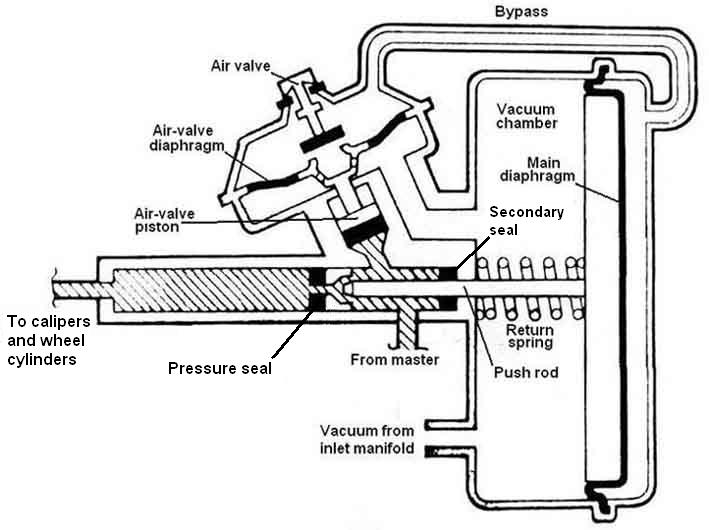

Cross-section of a caliper from the Leyland Workshop Manual. As fluid is forced into the caliper it pushes the pistons out, which press the pads against the disc. Unlike wheel cylinders the seals are retained in the caliper body. As the piston moves out it tends to pull the seals with it a little and distort them slightly. When the fluid pressure is released the seals tend to return to their former position, pulling the pistons with them, so releasing the pressure of the pads against the disc.

Cross-section of a caliper from the Leyland Workshop Manual. As fluid is forced into the caliper it pushes the pistons out, which press the pads against the disc. Unlike wheel cylinders the seals are retained in the caliper body. As the piston moves out it tends to pull the seals with it a little and distort them slightly. When the fluid pressure is released the seals tend to return to their former position, pulling the pistons with them, so releasing the pressure of the pads against the disc.

Piston cut-outs:

Most calipers seem to sport pistons with a cut-out in one part of the surface that bears against the pad. Who knows why? Especially when on the MGB it is supposed to be facing in towards the spindle, on the MGA facing outwards, and on the Midget facing up or down! When looking at an MGB caliper it can be seen that the piston is not central to the pad, but offset towards the spindle, so much so that the inner edge of the piston is not even on the pad. However, with the cut-out, as can be seen from the witness marks on a pad, the remaining contact surface between piston and pad is pretty-well slap bang in the middle of the pad and will give an even pressure of pad against disc. That could well explain the MGB orientation, but the MGA and Midget are something else.

Most calipers seem to sport pistons with a cut-out in one part of the surface that bears against the pad. Who knows why? Especially when on the MGB it is supposed to be facing in towards the spindle, on the MGA facing outwards, and on the Midget facing up or down! When looking at an MGB caliper it can be seen that the piston is not central to the pad, but offset towards the spindle, so much so that the inner edge of the piston is not even on the pad. However, with the cut-out, as can be seen from the witness marks on a pad, the remaining contact surface between piston and pad is pretty-well slap bang in the middle of the pad and will give an even pressure of pad against disc. That could well explain the MGB orientation, but the MGA and Midget are something else.

When I changed Keith's clutch a week ago I'd noticed the car pulling quite strongly to the right on braking, but hadn't realised his MOT was so close, and it failed on that and emissions. Pistons and seals are £40 for a full set but I really don't like fiddling with caliper internals (I'd opted to swap Vee's calipers outright when she had a similar problem), and complete calipers were £40 each (not bad considering the clutch slave was also £40). So we thought it worth trying to clean the pistons up a bit and exercising them in and out. The inner piston on the right-hand caliper was very stiff as was the outer piston on the left-hand. I took the pads out and although there was plenty of meat on three of them I noticed the material was crumbling away, something I hadn't seen before (before Bee's caliper stuck on, that is). The 4th pad had worn quite a bit more and at an angle. Also noticed the left-hand disc was pretty new whereas the right-hand looked original and noticeably thinner. One caliper may also have been changed previously as only the right-hand caliper had the cut-outs in the pistons. I wedged a block of wood between the disc and the fully retracted 'good' piston so I could lever the 'bad' piston in without distorting the disc too much. Pumped the 'bad' piston fully out, then dipped some coarse twine in brake fluid, wrapped it round the piston and pulled the string back and fore to scour the surface of the piston. Also dribbled a little fluid round the edge of the seal, then started working the piston in and out several times. Both 'bad' pistons noticeably lightened up to something much closer to the 'good' pistons. Cleaned off any excess brake fluid from the pistons and refitted the pads, using an old one from Bee that had plenty of meat on it in place of the badly worn one. On a test drive it was much better, but still pulled very slightly to the right under heavy braking when not holding the wheel. So I decided to clean the 'good' piston on the left-hand side as well. Might have been slightly improved after that, but still pulling very slightly. I know there is a limit of imbalance but had no idea how close it was to that limit, but Keith thought it worth a punt at a retest, and it was declared 'fine' so many of Keith's quids saved. Before that I also reset the carbs, which seemed very close in both balance and mixture, but I did weaken it by an 1/8th turn which showed as about 3.9%CO on my Gastester and 3.8% on the retest and also OK (limit being 4.5%). He does need new pads though, and the rear brakes looking at as the pedal is a bit 'long' for both our tastes, so that will probably be the next job.

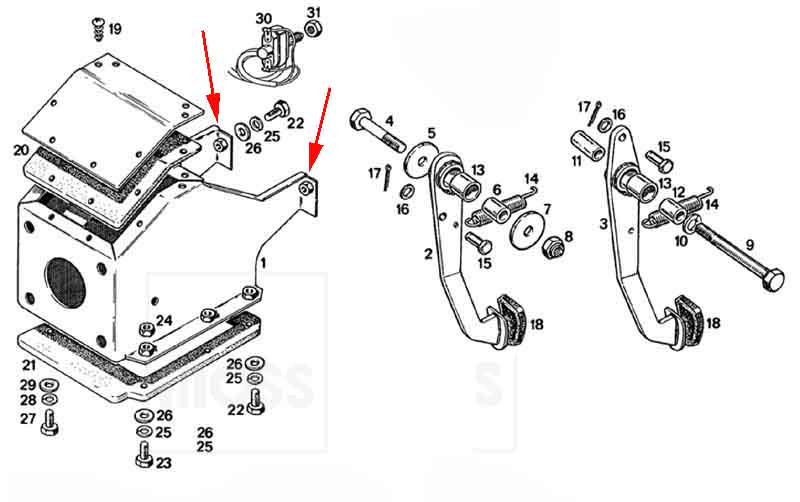

V8 Calipers:

These are an odd-ball consisting of an MGB outer casting and a Triumph 2.5 saloon inner casting. This means the pads are handed - inner and outer.

Caliper and Disc Change Added May 2009